Spiral stirrer

A helical and helical technology, applied in mixers with rotating stirring devices, chemical/physical/physical-chemical stationary reactors, dissolution, etc., which can solve the problems of insufficient stirring, single U-shaped stirring blade turbine, and complicated equipment welding. and other problems, to achieve the effect of convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

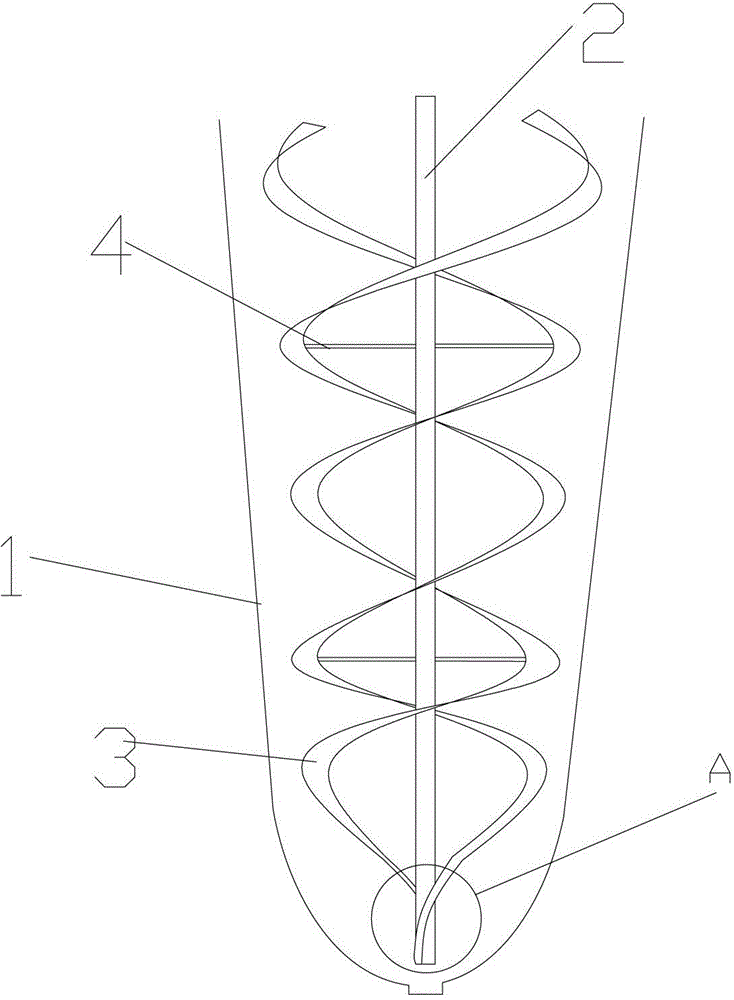

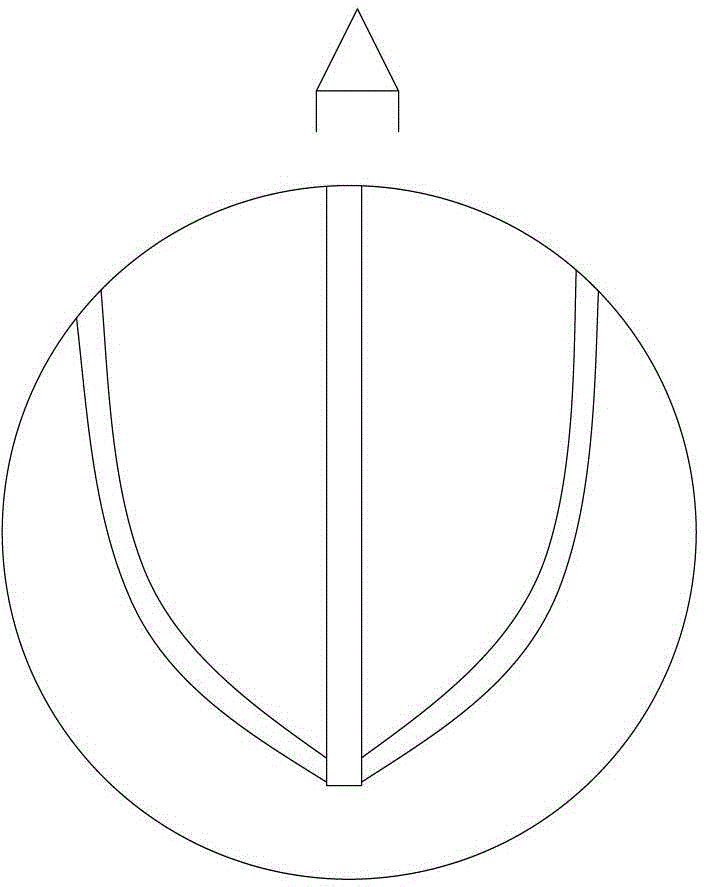

[0012] As shown in the figure, the spiral stirring includes a reaction tank 1, a rotating shaft 2, a stirring rod 3 and a support 4. The reaction tank is placed vertically, and the rotating shaft is vertically set at the center of the reaction tank and powered by a motor. The stirring rod is in a double helix structure around the rotating shaft. Setting, the bottom of the stirring rod is U-shaped, and the structure can be designed with the bottom shape of the reaction tank. The bottom of the stirring rod is fixedly connected with the bottom of the rotating shaft. The stirring rod is a segmented structure, and the spiral part is 3 sections. There are 3 supports.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com