A bend pipe shape detection system and detection method thereof

A detection system and detection method technology, applied in the field of pipe bending, can solve the problems of long time consumption, high cost, large equipment investment, etc., and achieve the effect of eliminating the superposition of detection errors, avoiding the superposition of errors, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

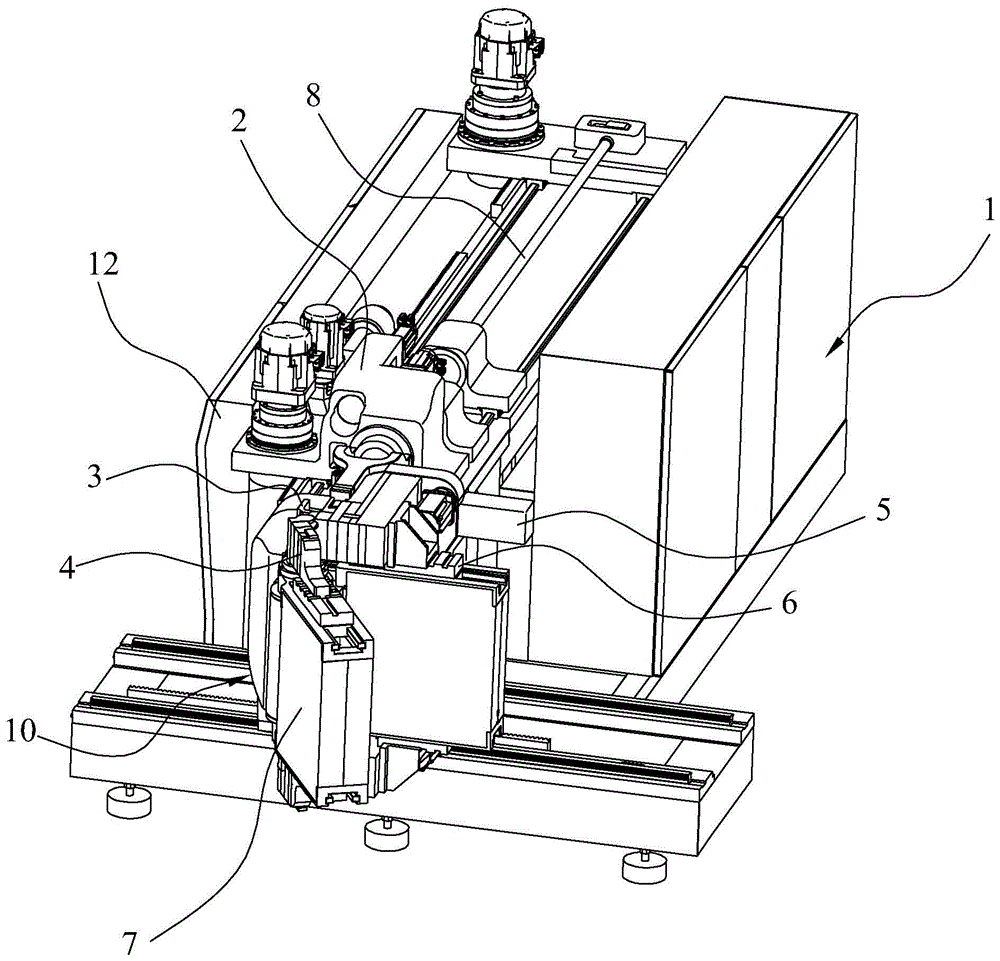

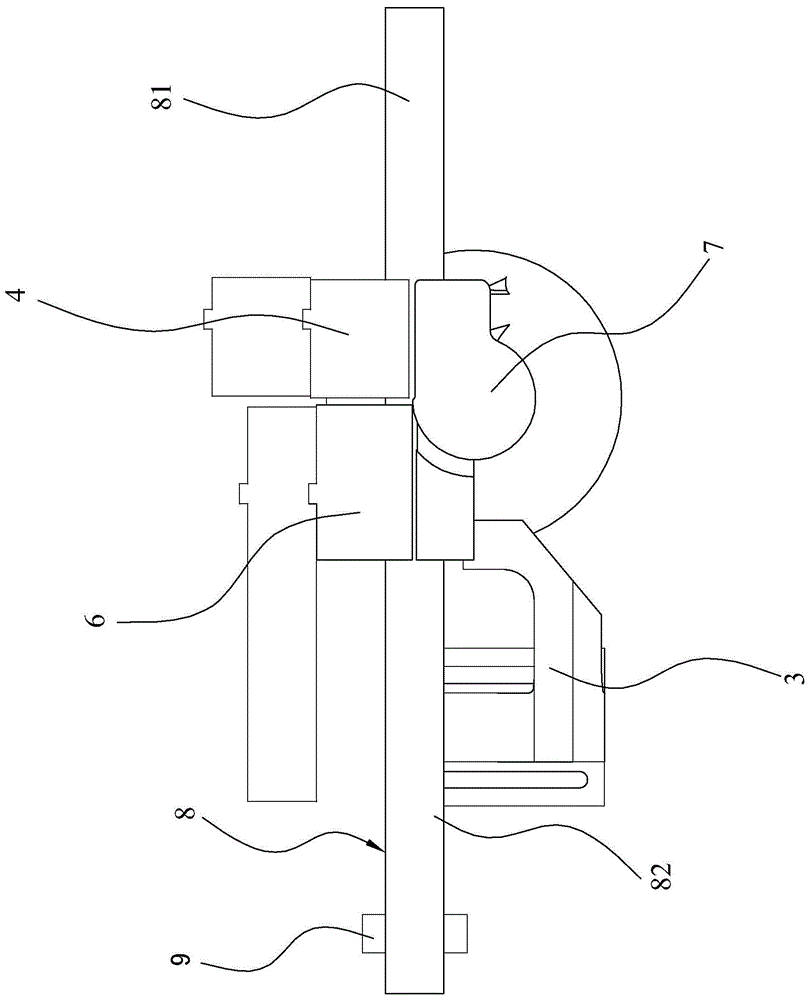

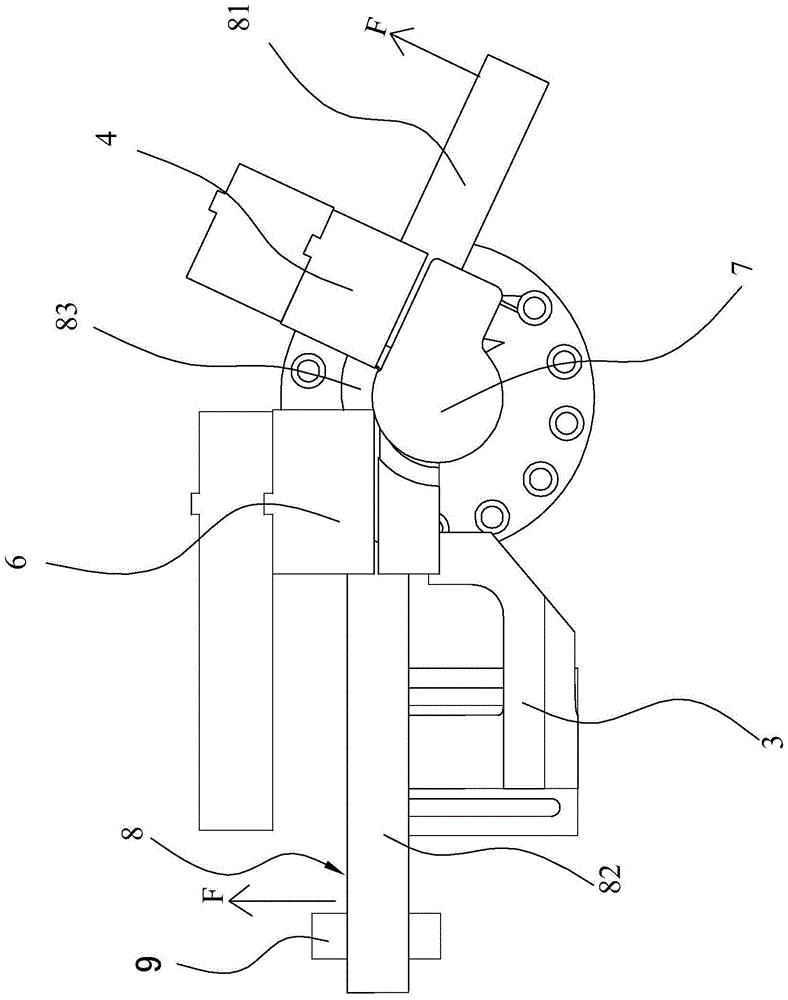

[0037] Such as Figure 1~5As shown, a bend pipe shape detection system includes a numerically controlled pipe bender 1, a pipe shape detection device and a control system (not shown) for processing detection information. In this embodiment, the pipe shape detection device is a measuring distance A sensor 11, such as a laser ranging sensor, is installed on the CNC pipe bender 1 on the same plane as the processed pipe fitting 8 on the CNC pipe bender 1, and the output of the sensor 11 is connected to the detection information. Processing the input of the control system, the springback angle of the pipe 8 is calculated using geometrical principles. The CNC pipe bending machine 1 includes a frame 12 and a machine head 10. The frame 12 is provided with a feeding trolley 2 for fixing and pushing the pipe fittings 8. The machine head 10 is provided with a main mechanism for clamping the pipe fittings 8 in cooperation with the pipe bending die 7. The clamp 4 and the auxiliary clamp 6...

Embodiment 2

[0044] Such as Figure 1~3 As shown, different from Embodiment 1, the pipe shape detection device in Embodiment 2 includes an auxiliary clamp 6 and a second servo motor 5 used to control the action of the auxiliary clamp 6, that is, directly uses the auxiliary clamp 1 of the CNC pipe bender 1. The clip 6 and the second servo motor 5 are used as a sensor for measuring distance to detect the rebound distance of the pipe fitting 8, the output of the second servo motor 5 is connected to the input of the control system for processing the detection information, and the output of the control system is connected with the control system simultaneously. The input of the second servo motor 5 is connected, and the detection information is fed back to control the action of the auxiliary clamp 6 through the second servo motor 5. The principle is: the auxiliary clamp 6 of the CNC pipe bending machine 1 is controlled by the second servo motor 5. The auxiliary push clamp arm moves up, and once...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com