Device for measuring sound absorption coefficient of acoustic material by use of pulse method and measuring method

A technology of sound absorption coefficient and acoustic material, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve the problems of cumbersome testing work and increase testing time, and achieve the effect of avoiding secondary errors and overcoming phase matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Describe the present invention below in conjunction with specific embodiment:

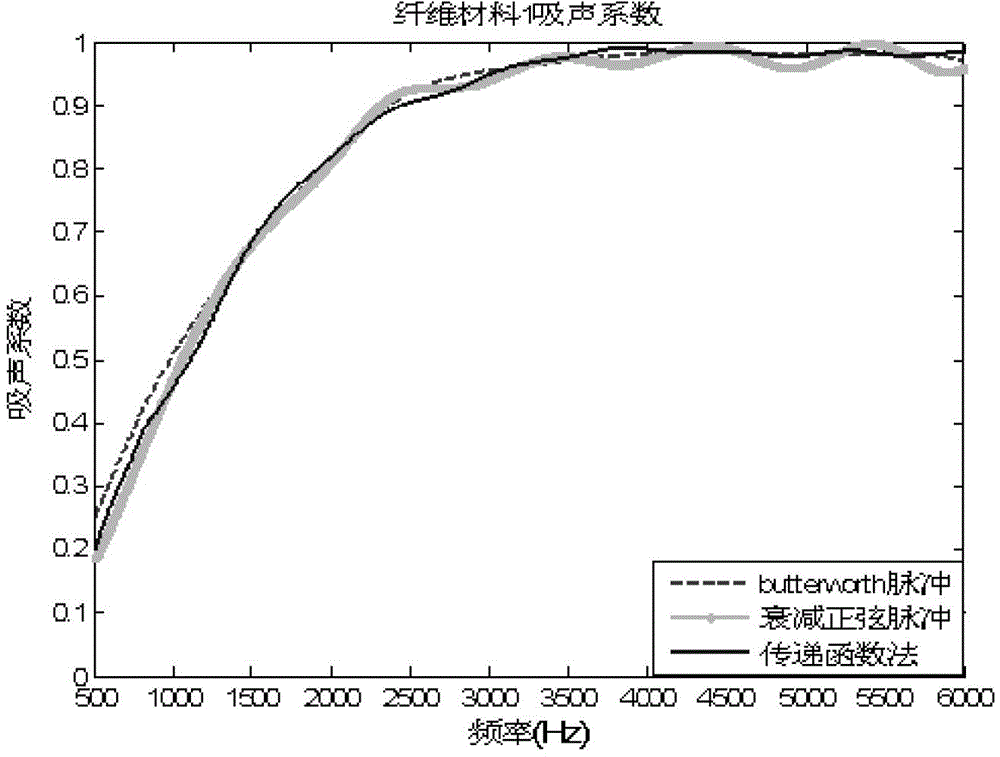

[0025] In this example, a measurement experiment of sound absorption coefficient was carried out on a fiber material with a thickness of 25 mm.

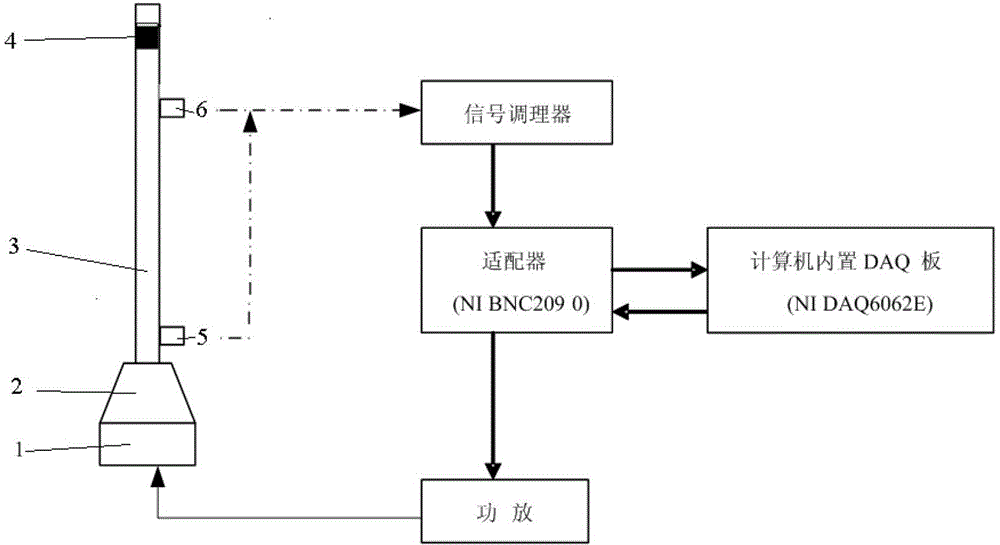

[0026] The measuring device used in this embodiment includes a sound tube, a pulse sound source, a microphone, a power amplifier, a signal conditioner, an adapter, and a data acquisition device.

[0027] The sound tube is composed of a large-diameter cylindrical tube, a conical tube and a small-diameter cylindrical tube which are coaxially and fixedly connected in turn. Tube length is 1360mm. The inner diameter of the large-diameter cylindrical tube is the same as the diameter of the pulse sound source. The pulse sound source is installed in the large-diameter cylindrical tube. The inner and outer diameters of the small-diameter cylindrical tube are 27mm and 34mm, respectively, and are capable of propagating broadband plane pulse waves (frequency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com