Automatic tin soldering machine

An automatic welding and tin machine technology, which is used in welding equipment, auxiliary devices, metal processing and other directions to achieve the effects of long service life, fast material change and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

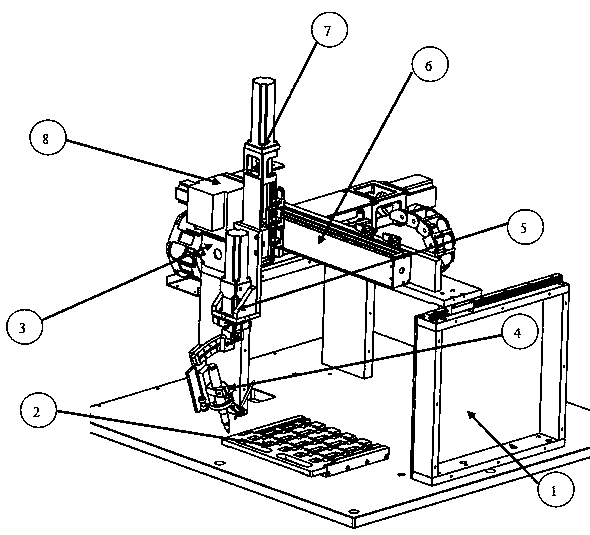

[0014] Automatic soldering machine, including support plate 1, carrier 2, Y-axis moving module 3, welding head 4, rotating axis 5, X-axis moving module 6, Z-axis moving module 7, tin wire storage module 8, and It is characterized in that there are multiple support plates 1, and the multiple support plates 1 support the X-axis mobile module 6 and the Y-axis mobile module 3 on a horizontal plane, intersecting in a T-shape, and the Z-axis mobile module 7 is arranged on the X-axis mobile module. 6, the upper end of the Z-axis moving module 7 is provided with a tin wire storage module 8, the lower end of the Z-axis moving module 7 is connected to a rotating shaft 5, the lower end of the rotating shaft 5 is fixed with a welding head 4, and the carrier 2 is set on a multi-block support between plates 1. The X-axis moving module 6, the Y-axis moving module 3, and the Z-axis moving...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap