Film lamination method

A film and surface film technology, applied in chemical instruments and methods, laminating devices, packaging, etc., can solve the problems of easy dust absorption on the screen and pasting surface, easy damage to the film body, and affecting the display effect of the screen, so as to reduce the exposed area time, to avoid the effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

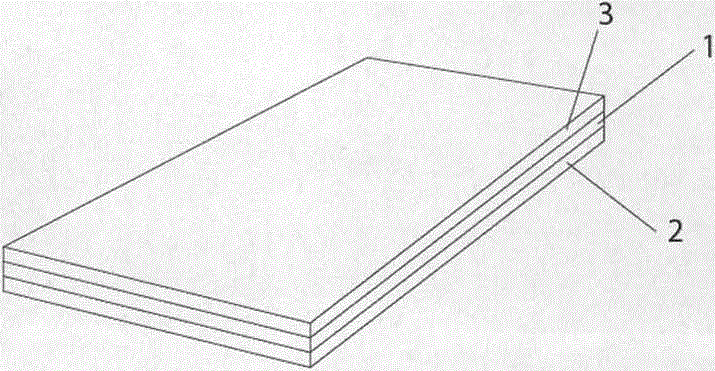

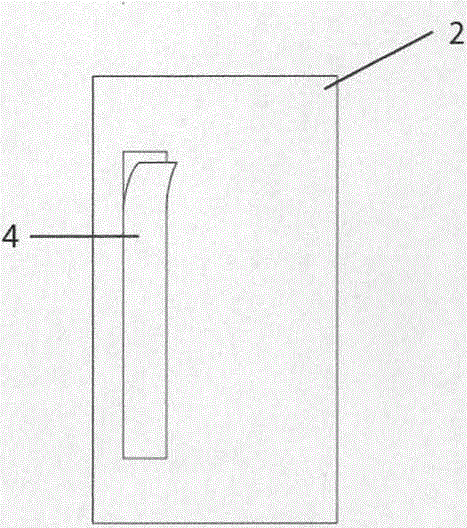

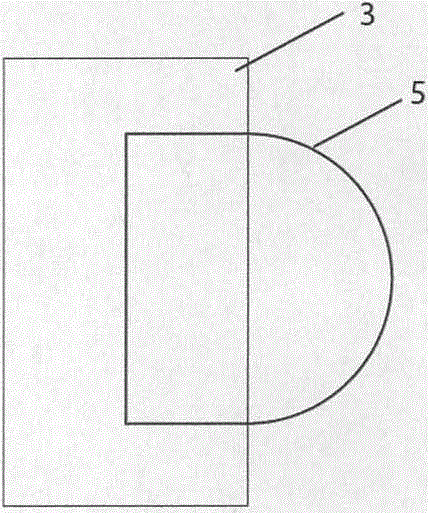

[0026] Such as figure 1 , 2 , 3, and 4, the protective film described in this embodiment has a five-layer structure, which includes an intermediate use layer 1, a base film 2 attached to the lower surface of the use layer and a surface film 3 attached to the upper surface of the use layer, located at the bottom The elongated low-viscosity double-sided adhesive strip 4 on the surface of the film and the fixing strip 5 attached to the longer side of the film, the fixing strip is partially exposed, and the exposed part is provided with an adhesive protective sheet 6 .

[0027] Like this, put the protective film on the screen to determine the pasting position before implementing the film, and fix the protective film on the screen surface by the double-sided adhesive tape 4. If there is a deviation in the position, you can take it off and align it again at any time. After the pasting is completed, Tear off the adhesive protection sheet 6, and tightly fix the adhesive surface of th...

Embodiment 2

[0029] Such as Figure 9 As shown, this embodiment describes a curved screen that is popular in the market at present. The protective film cannot completely cover the curved part of the screen. It is usually smaller than the screen and avoids the curved part. It should be pasted on the screen. In this way, the screen protective film can be fixed on the screen and the back of the screen through the fixing strip attached to the surface film, forming a page structure on the screen that can be opened at will.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com