Hub tool vehicle

A technology for wheel hub workers and tooling vehicles, which is applied in the field of machinery and can solve problems such as mutual collision, limited loading, and bump marks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

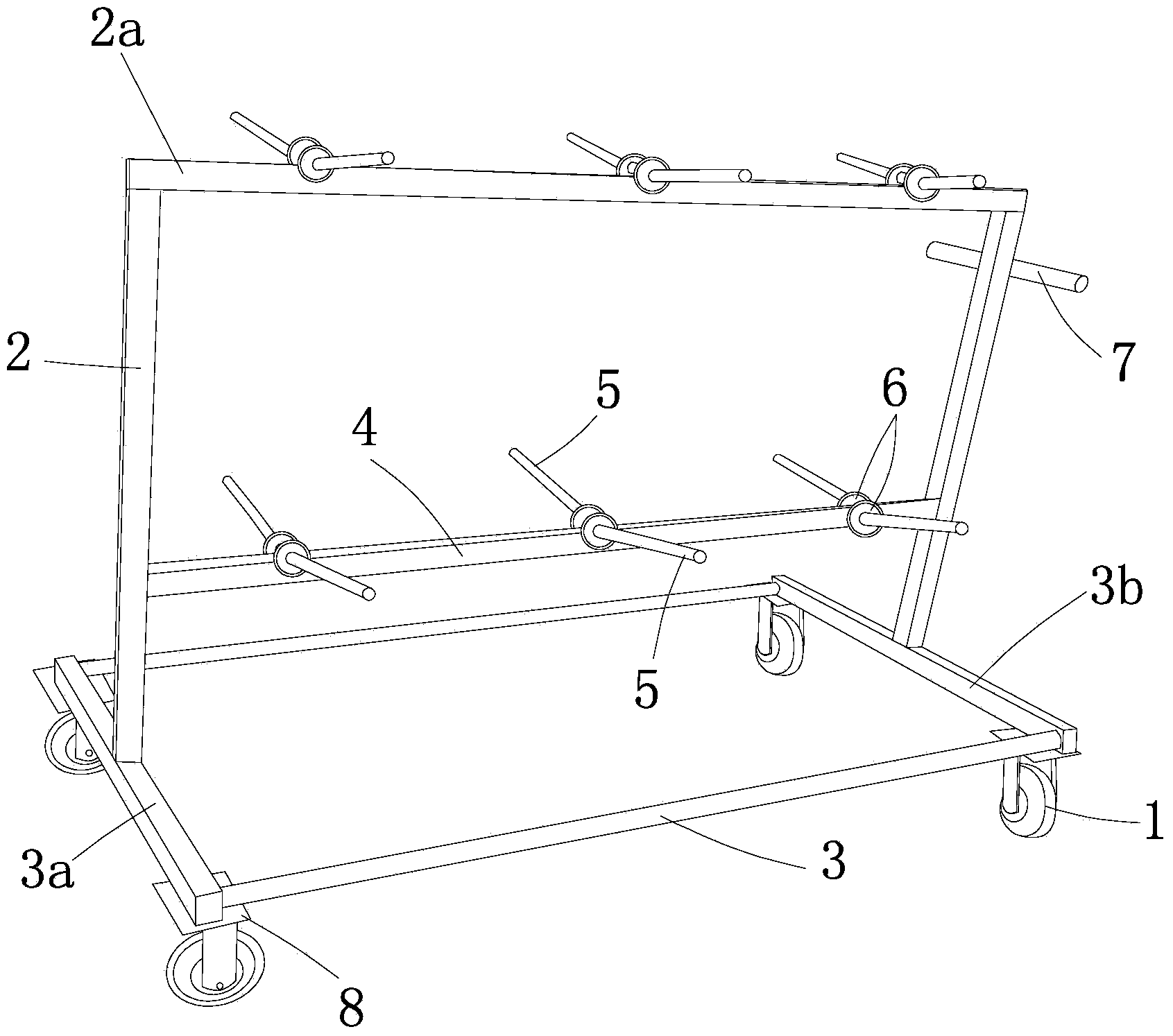

[0011] like figure 1 The shown hub tooling vehicle is mainly composed of tooling frame main body, universal wheel 1, horizontal connecting rod 4, suspension slanting rod 5, plastic spacer 6, horizontal handrail rod 7, horizontal mounting plate 8 and so on.

[0012] There are totally four universal wheels 1, which are arranged below the main body of the tooling frame and arranged in a rectangle. The main body of the tooling frame is welded by a "door" shaped frame 2 and a rectangular frame 3 at the bottom.

[0013] The left lower end of " door " shape frame 2 is vertically welded in the left horizontal bar 3a middle part of rectangular frame 3 , and the right lower end of " door " shape frame 2 is vertically welded in the right horizontal bar 3b middle part of rectangular frame 3 . The middle part of " door " shape frame 2 is welded with the transverse c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com