Automotive low-cost high-formability aluminum alloy material and preparation method thereof

A technology of aluminum alloy materials and aluminum alloy sheets, which is applied in the field of low-cost and high-formability aluminum alloy materials for automobiles and its preparation, can solve the problems of low production cost, unsatisfactory stamping performance and bending performance, and reduce production costs , Excellent paint hardening properties, excellent stamping performance and the effect of bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

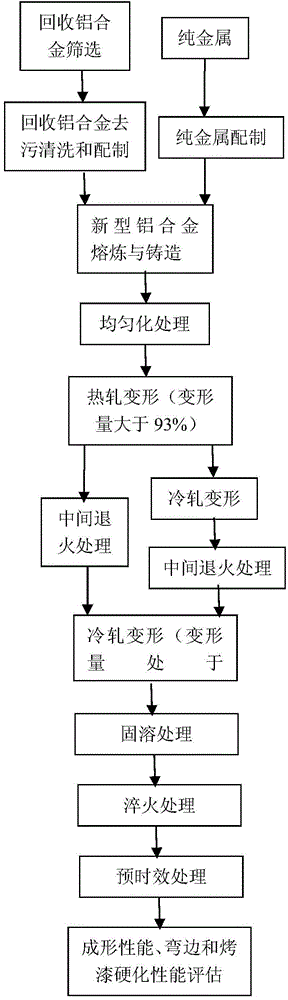

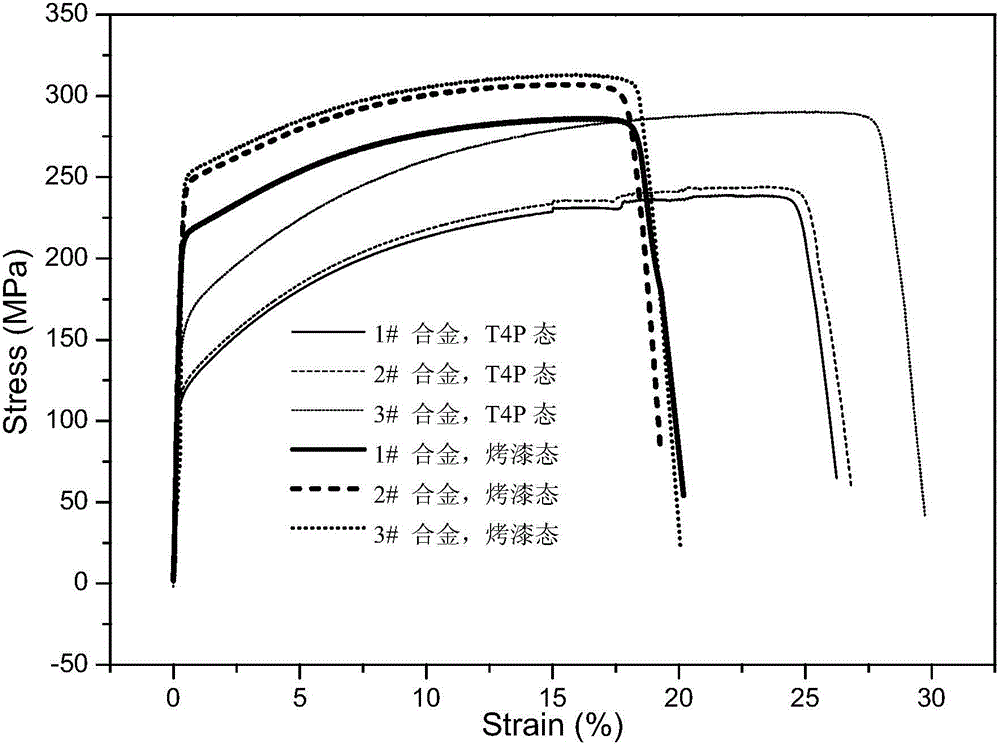

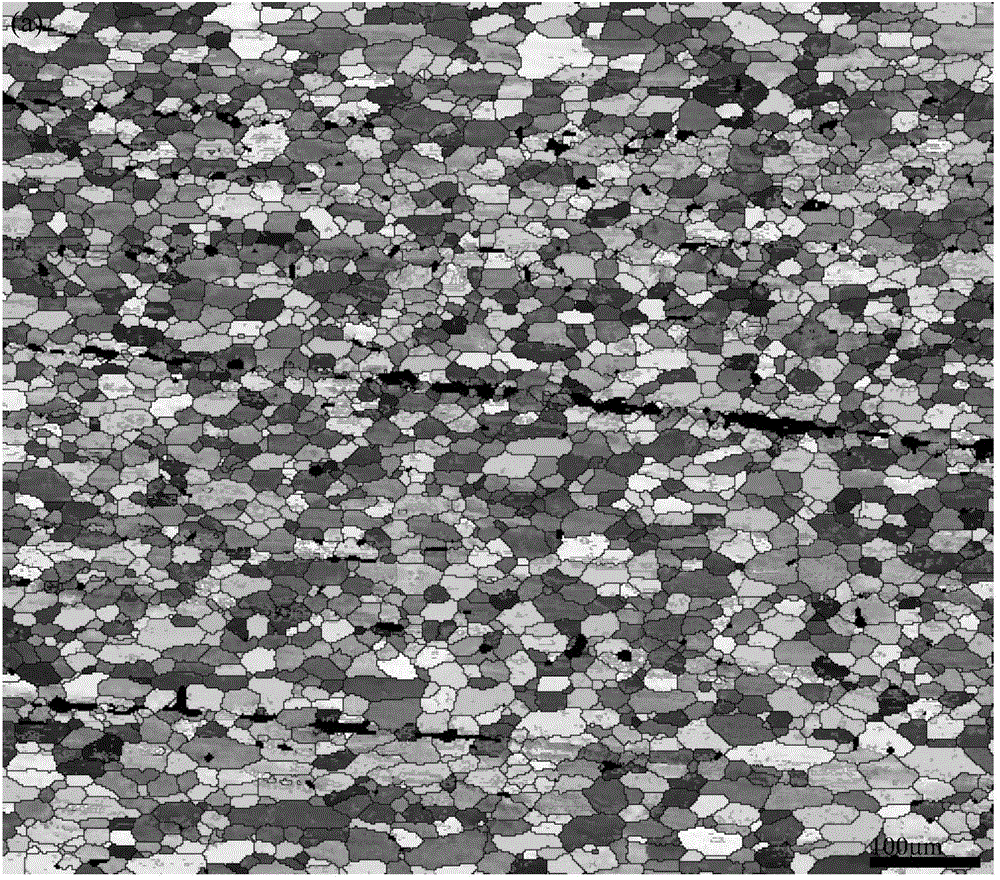

[0036] Implement the invention alloys 1#, 2# and 3# after smelting and casting, and homogenize them. The treatment process is: start to heat up at a heating rate of 20°C / h, wait for the temperature to reach 540-560°C for 14 hours, and then use The cooling rate of 20°C / h is taken out when the temperature of the furnace is lowered to 100°C. After homogenization, the ingot is cut and milled, reheated to 520-560°C for hot rolling, the pass reduction is 3%-30%, the total deformation of hot rolling is >93%, and the final rolling temperature is lower than 300°C ;The hot-rolled plate is heated to 350-550°C at a heating rate of 30°C / h for 1.2h annealing treatment, cooled by air cooling, and then cold-rolled to a thickness of 1mm, and the pass reduction is at 8 ~30%, the total deformation is 50~88%; then directly cut the sample from the cold-rolled plate and place it in a heat treatment furnace at 545~555°C for 3min solution treatment, and the heating rate of the sample is greater than ...

Embodiment 2

[0038] After implementing the invention alloys 1# and 2#, after smelting and casting, they are homogenized. The treatment process is: start heating at a heating rate of 20°C / h, wait for the temperature to reach 540-560°C for 14 hours, and then heat at 20°C / h The cooling rate of h is to take out the sample when the temperature of the furnace is lowered to 100 °C. After homogenization, the ingot is cut and milled, reheated to 520-560°C for hot rolling, the pass reduction is 3%-30%, the total deformation of hot rolling is >93%, and the final rolling temperature is lower than 300°C ;The hot-rolled plate is heated to 350-550°C at a heating rate of 30°C / h for 1.2h annealing treatment, cooled by air cooling, and then cold-rolled to a thickness of 1mm, and the pass reduction is at 8 ~30%, the total deformation is 50~88%; then directly cut the sample from the cold-rolled plate and place it in a heat treatment furnace at 545~555°C for 3min solution treatment, and the heating rate of the...

Embodiment 3

[0040] Implement the invention alloy 4# and 5# after smelting and casting, and homogenize them. The treatment process is: start heating at a heating rate of 30°C / h, wait for the temperature to reach 540-560°C for 21 hours, and then heat at 30°C / h The cooling rate of h is to take out the sample when the temperature of the furnace is lowered to 100 °C. After homogenization, the ingot is cut and milled, reheated to 520-560°C for hot rolling, the pass reduction is 3%-30%, the total deformation of hot rolling is >93%, and the final rolling temperature is lower than 300°C ;The hot-rolled plate is heated to 350-550°C at a heating rate of 200°C / h for 2h annealing treatment, cooled by air cooling, and then cold-rolled to a thickness of 1mm, and the pass reduction is between 8 and 3. 30%, the total deformation is 50-88%; then directly cut the sample from the cold-rolled plate and place it in a heat treatment furnace at 545-555°C for 7min solution treatment, and the heating rate of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap