A dynamic three-dimensional compact fushun ring spinning method

A ring spinning, three-dimensional technology, applied in the field of textile processing, can solve the problems of smaller yarn triangle area, inability to continuously and uniformly gather spinning, consume large negative pressure gas, etc., achieve narrow distribution width, and suppress hairiness , Improve the effect of yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

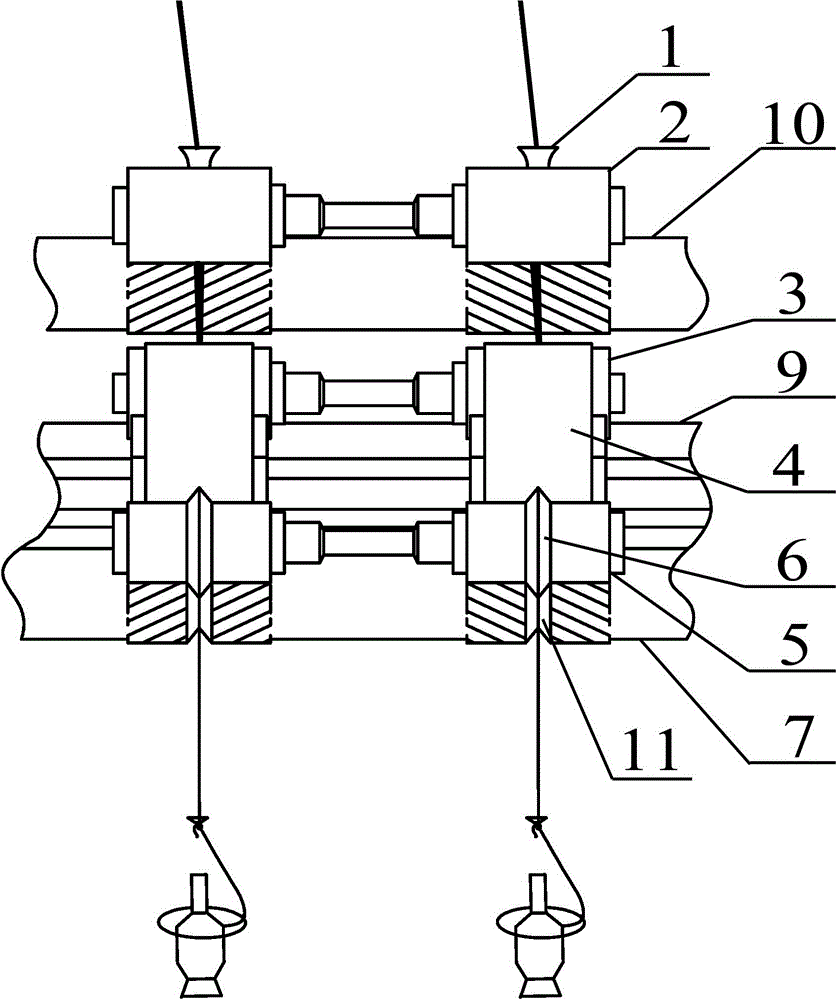

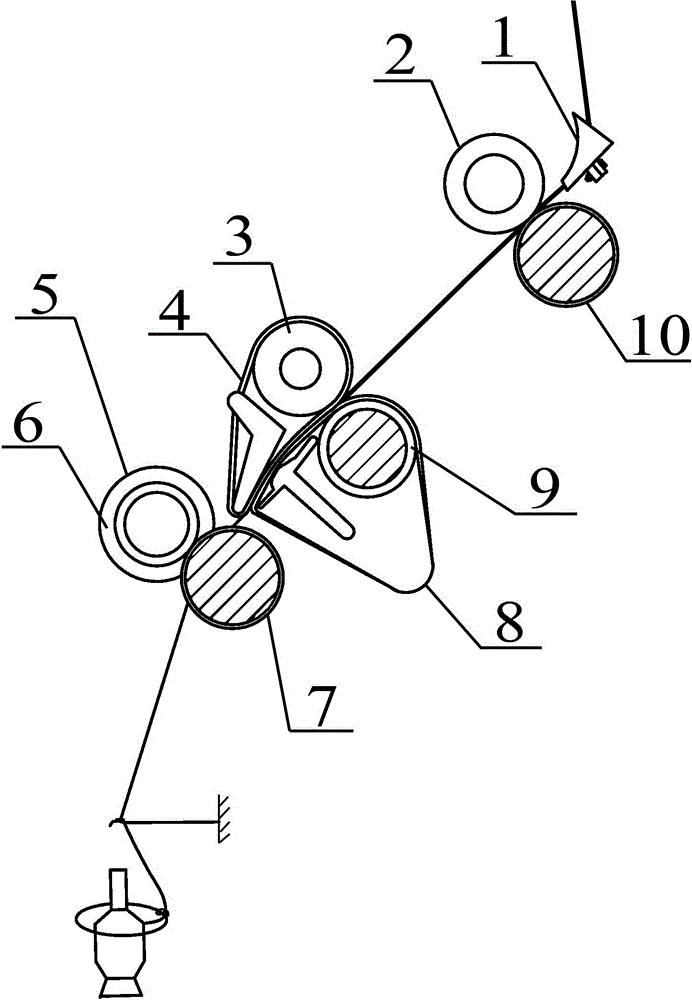

[0012] A dynamic three-dimensional compact fushun ring spinning method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] see Attachment.

[0014]A dynamic three-dimensional compact Fushun type ring spinning method. In each drafting system of the spinning frame, the roving unwound from the roving creel passes through the yarn feeding horn 1 and enters the rear roller 10, rear rubber roller 2, and middle roller. The drafting system is composed of bottom roller 9, bottom apron 8, middle top roller 3, top apron 4, front roller 7, and front rubber roller 5. At least one beard gathering groove is provided on the outer surface of front roller 7 along the circumferential direction 11. The beard gathering groove 11 is V-shaped, and a boss 6 corresponding to the beard gathering groove 11 is added on the outer surface of the front rubber roller 5 along the circumferential direction. The boss 6 is V-shaped, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com