Road cone put-away and release device of automatic traffic cone put-away and release trolley

A technology of automatic retractable and retractable devices, applied in traffic signals, roads, roads, etc., can solve the problems of no retractable accessories and achieve high retractable efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

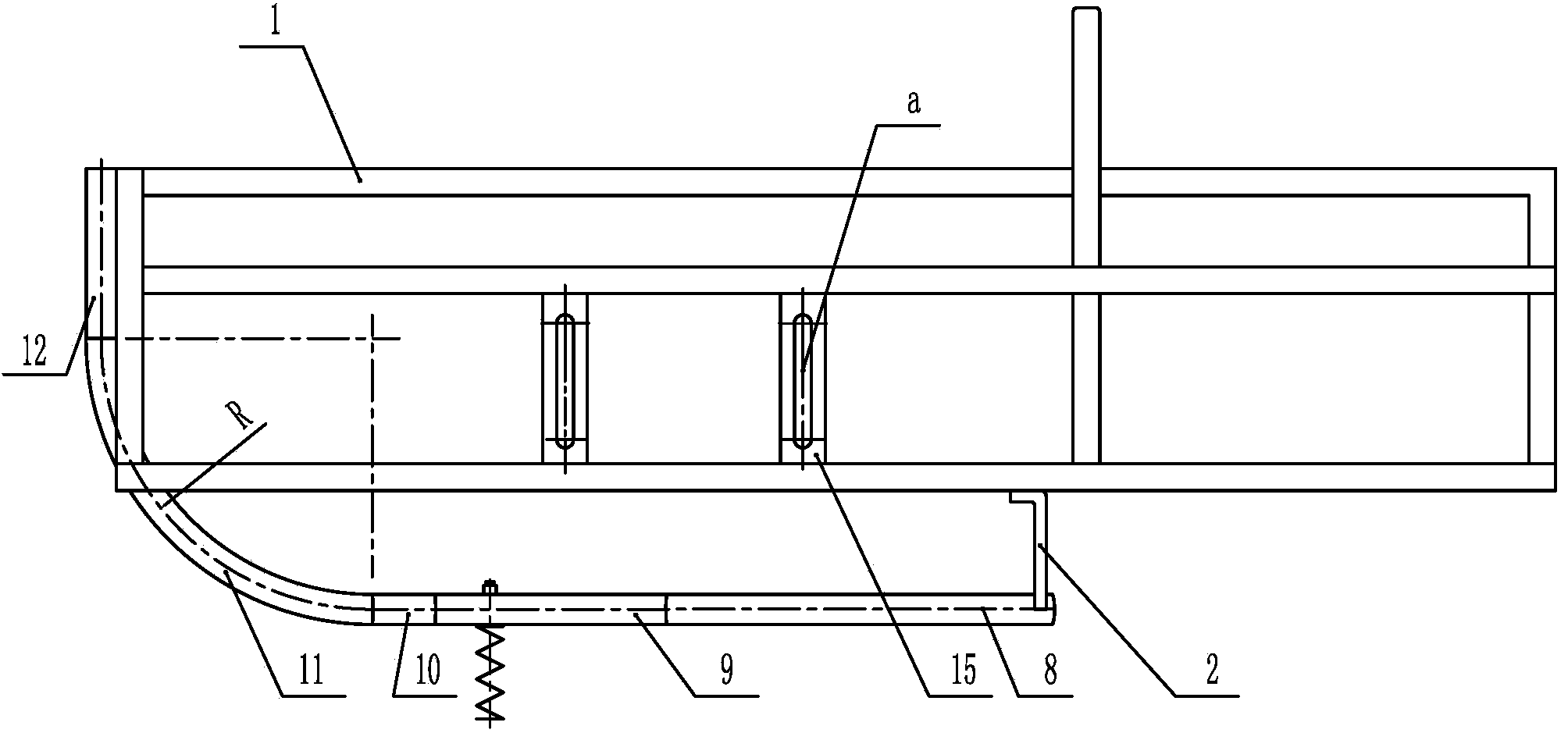

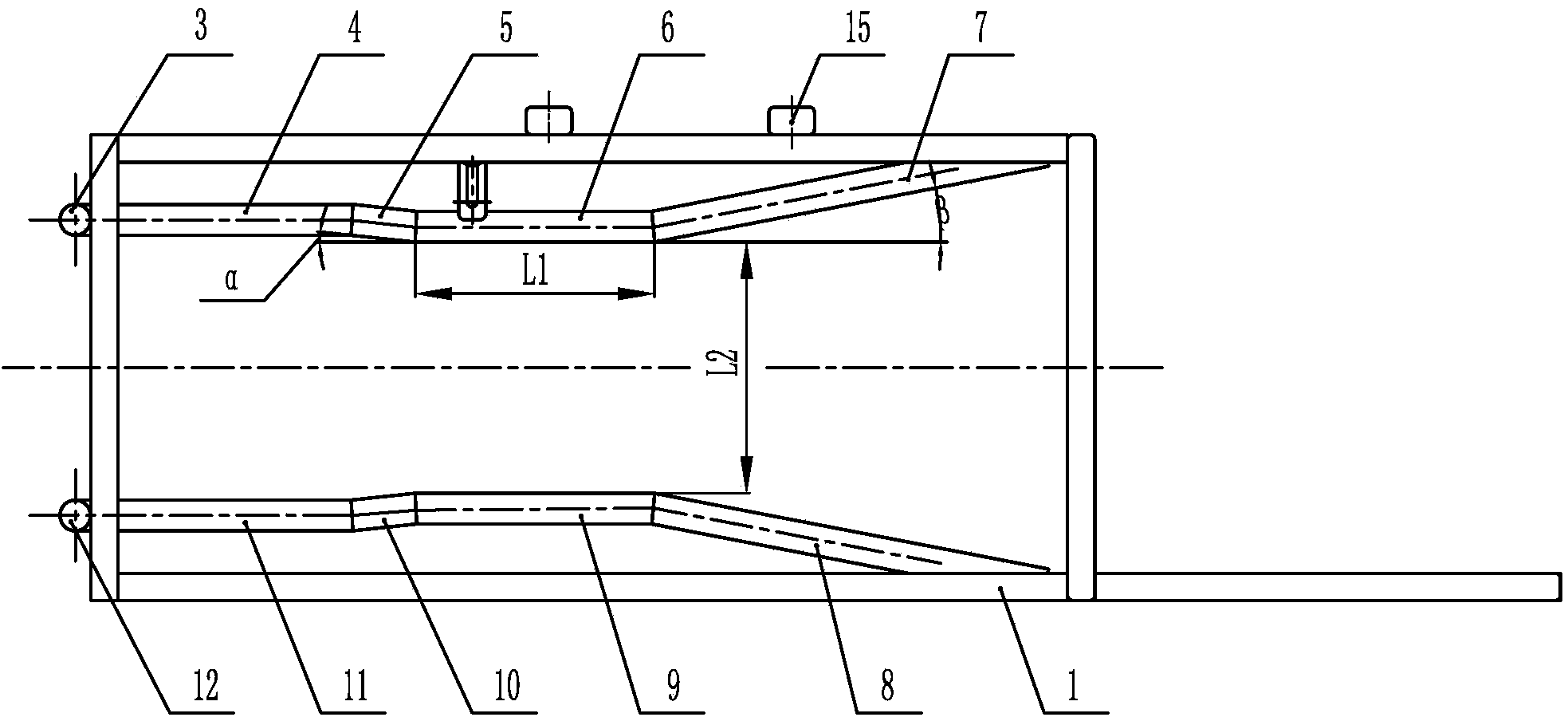

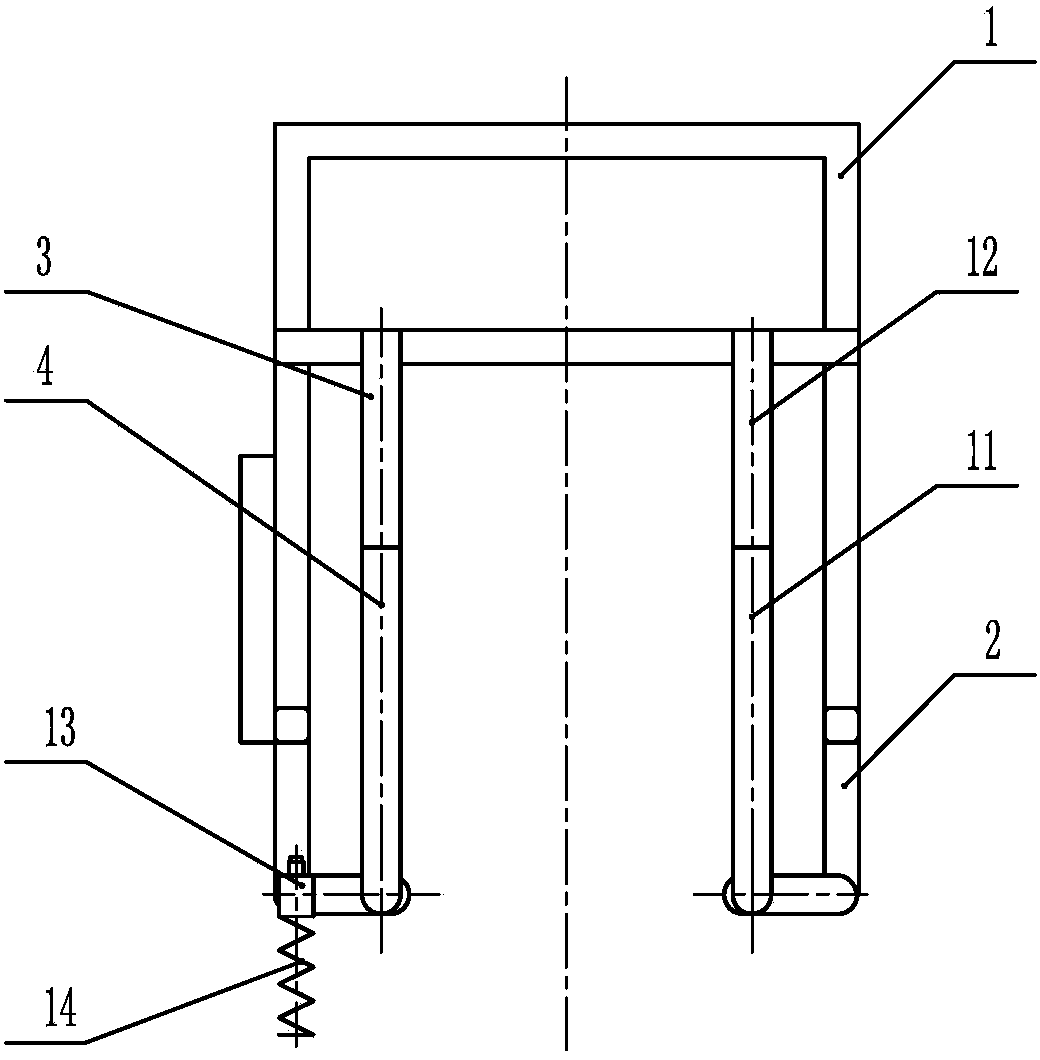

[0022] exist figure 1 , 2 , 3, the road cone retractable device of the traffic cone automatic retractable car of the present embodiment consists of a retractable frame support frame 1, a connecting plate 2, a rear vertical connection pipe 3, a rear righting pipe 4, a rear righting transition pipe 5, Rear correction pipe 6, rear storage pipe 7, front storage pipe 8, front correction pipe 9, front centering transition pipe 10, front centering pipe 11, front vertical connecting pipe 12, setting seat 13, setting rod 14, middle reinforcing plate 15 connections constitute.

[0023] The geometric shape of the retractable frame support frame 1 is a rectangular parallelepiped frame structure, and a rear vertical connecting pipe 3 is welded on the left rear end of the retractable frame support frame 1, and a rear centralizing pipe 4 is welded at the bottom end of the rear vertical connecting pipe 3 , the rear centralizing pipe 4 is an arc-shaped elbow, the central angle of the arc is ...

Embodiment 2

[0026]The rear vertical connection pipe 3 is welded on the left rear end of the retractable frame support frame 1 of this embodiment, and the rear vertical connection pipe 3 is welded with a rear centralizing pipe 4 at the bottom end of the rear vertical connecting pipe 3, and the rear centralizing pipe 4 is an arc-shaped elbow , the central angle of the arc is 80°, the arc radius R is 250mm, the other end of the rear centralizing pipe 4 is welded with a rear centralizing transition pipe 5, and the center line of the rear centralizing transition pipe 5 is connected to the bottom surface of the retractable frame support frame 1 The included angle ɑ between the center lines is 3°, and the other end of the transition pipe 5 is welded with a rear rectification pipe 6, the center line of the rear rectification pipe 6 is parallel to the center line of the bottom surface of the retractable frame support frame 1, and the rear rectification pipe 6 The length L1 is 200 mm. The other end...

Embodiment 3

[0028] The rear vertical connection pipe 3 is welded on the left rear end of the retractable frame support frame 1 of this embodiment, and the rear vertical connection pipe 3 is welded with a rear centralizing pipe 4 at the bottom end of the rear vertical connecting pipe 3, and the rear centralizing pipe 4 is an arc-shaped elbow , the central angle of the arc is 120°, the arc radius R is 380mm, the other end of the rear centralizing pipe 4 is welded with a rear centralizing transition pipe 5, and the center line of the rear centralizing transition pipe 5 is connected to the bottom surface of the retractable frame support frame 1 The included angle ɑ of the center line is 15°, the other end of the rear righting transition pipe 5 is welded with a rear correction pipe 6, the center line of the rear correction pipe 6 is parallel to the center line of the bottom surface of the retractable frame support frame 1, and the rear correction pipe 6 The length L1 is 400mm, the other end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Arc radius r | aaaaa | aaaaa |

| Arc radius r | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com