Pipe joint fast to install and detach

A pipe joint and fast technology, applied in the field of pipe joints, can solve the problems of long maintenance time, time-consuming and labor-intensive, and large workload, and achieve the effects of saving manpower and material resources, saving maintenance time, and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

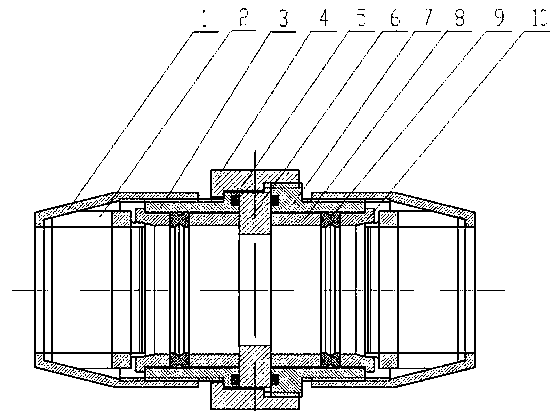

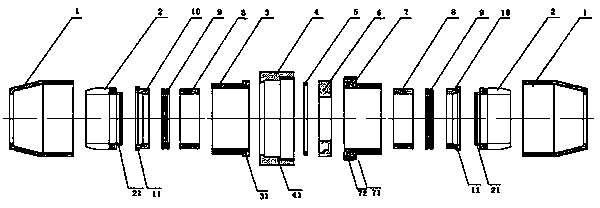

[0017] The application will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, the quick installation and disassembly pipe joint provided by this application includes the following components: lock nut 1, elastic snap ring 2, joint body a3, nut 41, nut coupling piece 4, sealing ring a5, spacer sleeve a6, joint body b7, The retaining ring 8, the seal ring b9 and the spacer b10, the connection relationship of the above components is as follows: with the nut connecting piece 4 as the center, the left side is the joint body a3, the retaining ring 8, the seal ring b9, the spacer b10, and the elastic clip ring 2 and lock nut 1; on the right side of the nut are seal ring a5, spacer a6, joint body b7, retaining ring 8, seal ring b9, spacer b10, elastic snap ring 2 and lock nut 1; The lock nut 1 is set on the elastic snap ring 2, the spacer b10 is set on the groove 21 of the elastic snap ring 2, the retaining ring 8, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com