Blast hole explosion blocking method

A blasthole and orifice technology, which is applied in the field of open-air deep-hole step blasting and blockage construction of blasthole blasting, can solve problems such as rapid drop in detonation gas pressure, difficulty in ensuring blockage and compaction, and affect the safety of blasting operations. The effect of blasting effect, improving energy utilization rate, good practical effect and economic effect

Active Publication Date: 2015-02-25

CHINA GEZHOUBA GRP YIPULI CO LTD

View PDF4 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the above-mentioned dense material B is mainly used for dense plugging in blasthole blasting, and the plugging length generally accounts for about 1/3 of the blasthole depth. Large, and the blocking operation usually adopts manual operation, which leads to a very high labor intensity for workers

In addition, due to the large length of the plugging, it is difficult to ensure the compactness of the plugging.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Login to View More

Abstract

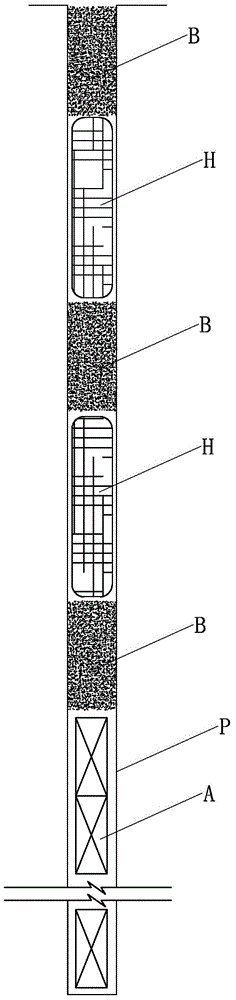

The invention discloses a blast hole explosion blocking method. The method includes the following construction steps that a, buffering air bags are obtained and are each of a cylindrical structure; b, an explosive is arranged at the middle portion in a blast hole, so that an explosive containing section is formed, then the blast hole is blocked through drilling cuttings, and therefore a dense blocked section is formed; c, the buffering air bags obtained in the step a are sequentially placed in the blast hole, so that a buffering air bag set is formed; d, the step b and the step c are finished repeatedly, so that dense blocked sections and the buffering air bags are arranged alternately; e, the blast hole is blocked through the drilling cuttings, blockage work of the remaining portion of a hole opening is finished, and the last dense blocked section is formed. According to the construction method, due to the fact that the buffering air bag set occupies a large space, the use number of blocking materials is reduced, and labor intensity of workers is relieved; the acting time of explosion gas in the blast hole can be prolonged, so that the explosion crushing effect is improved, the blast hole is effectively prevented from being punched, and the explosion operation safety level is improved.

Description

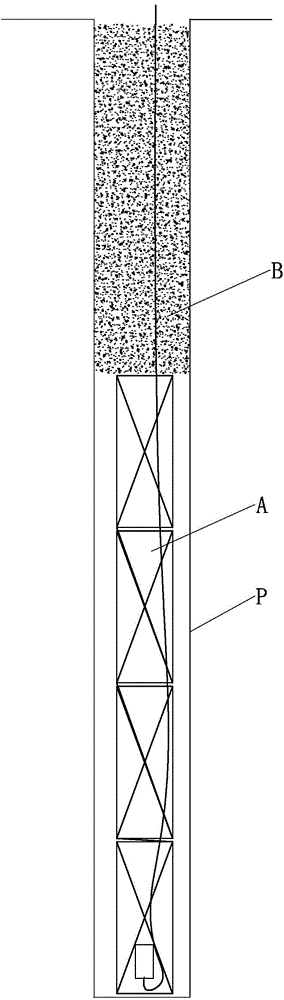

technical field [0001] The invention belongs to the technical field of engineering blasting, and relates to a plugging construction method for blasthole blasting. The construction method is especially suitable for open-air deep hole step blasting. Background technique [0002] Blast hole blasting method is the most common blasting construction method, the blast hole charge structure (such as figure 1 shown) is usually composed of a charge section A located in the middle and lower part of the blasthole P and a dense plugging section B located at the top of the blasthole, where the charge section is filled with explosives, and the plugging section is made of dense materials such as cuttings, mud, and crushed stones. Fill it tightly. After the explosive is detonated, it explodes in the blast hole to form a detonation wave. Under the joint action of the stress wave generated by the detonation wave and the expansion of the detonation gas, the blasting effect of crushing ore and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F42D1/18

Inventor 周桂松

Owner CHINA GEZHOUBA GRP YIPULI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com