Wiring harness tensile force test clamp capable of being moved and adjusted in multiple directions

A tensile test and multi-directional technology, applied in tension measurement and other directions, can solve problems such as waste of resources, poor extensibility, and unusability, and achieve the effects of improving efficiency, good extensibility, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

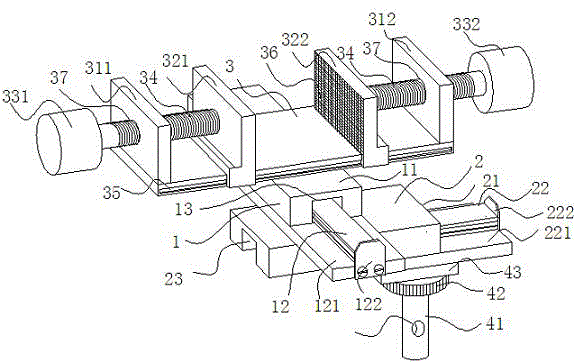

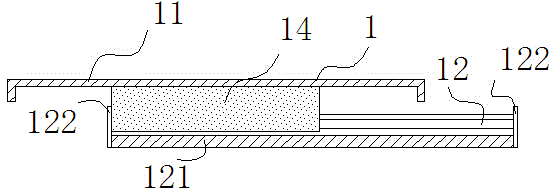

[0020] figure 1 It is a structural schematic diagram of the clamp embodiment of the present invention, such as figure 1 As shown, the test fixture includes a clamping part 3, a first sliding part 1, a second sliding part 1 and a mounting head 4. The clamping part 3 is arranged on the upper part of the first sliding part 1, and the first sliding part 1 and the second sliding part 1 are vertically connected and fixed, the sliding part can move and slide in a straight line, and cooperate with the second sliding part 1 to realize the multi-directional movement adjustment of the clip part 3.

[0021] The clamping part 3 includes a third slide rail 35, and the two ends of the third slide rail 35 are provided with fixed ends 311, 312, and also includes a first clamping end 321 and a second clamping end 322 sliding on the third slide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com