240V high-voltage direct current insulation monitoring system

An insulation monitoring, high-voltage DC technology, applied in the direction of testing dielectric strength, fault location, etc., can solve problems such as short circuit of DC power supply, affecting the safe operation of equipment in the equipment room, personal safety threats, etc., and achieve the effect of simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0017] The technical scheme of concrete implementation of the present invention is:

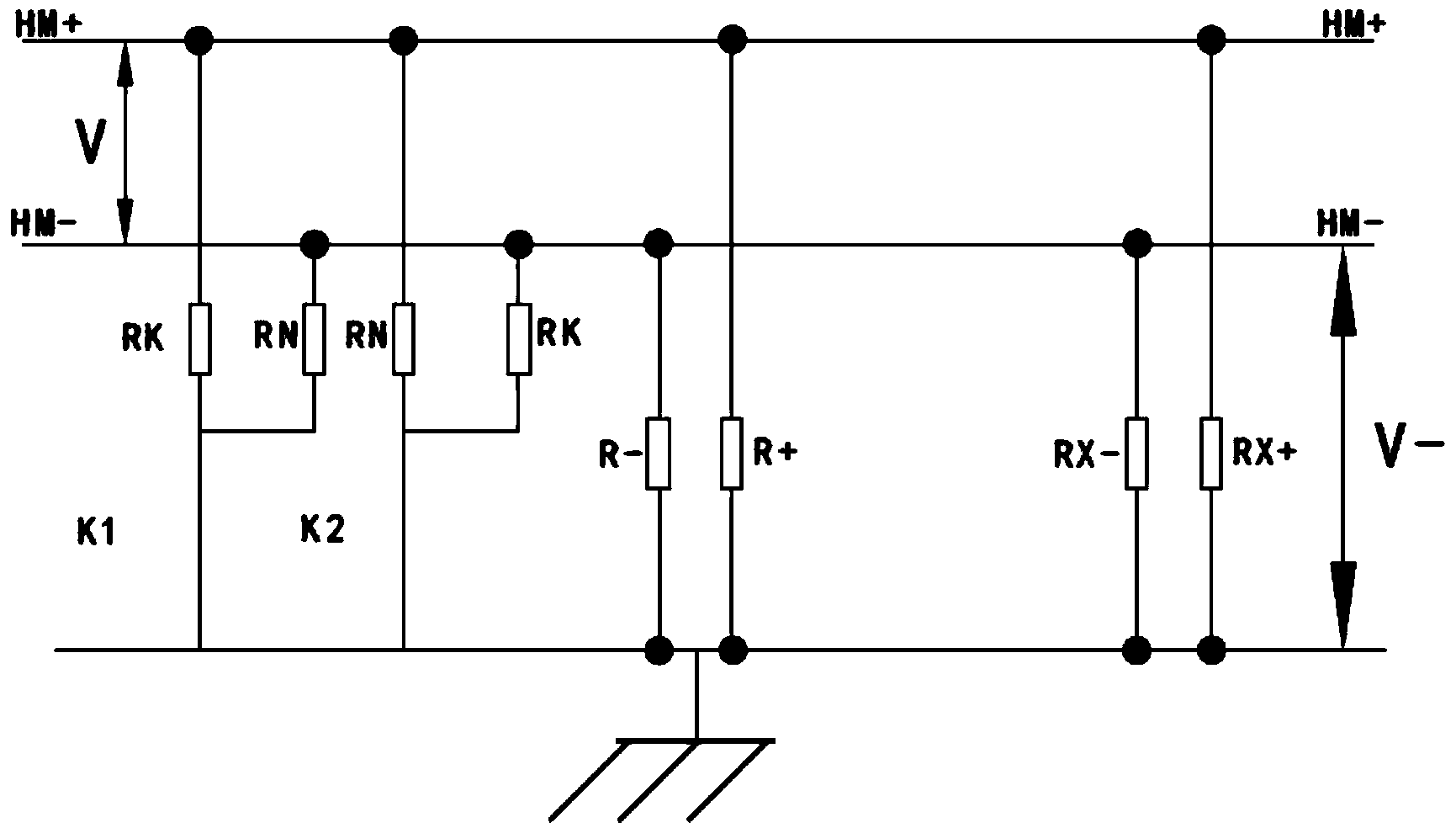

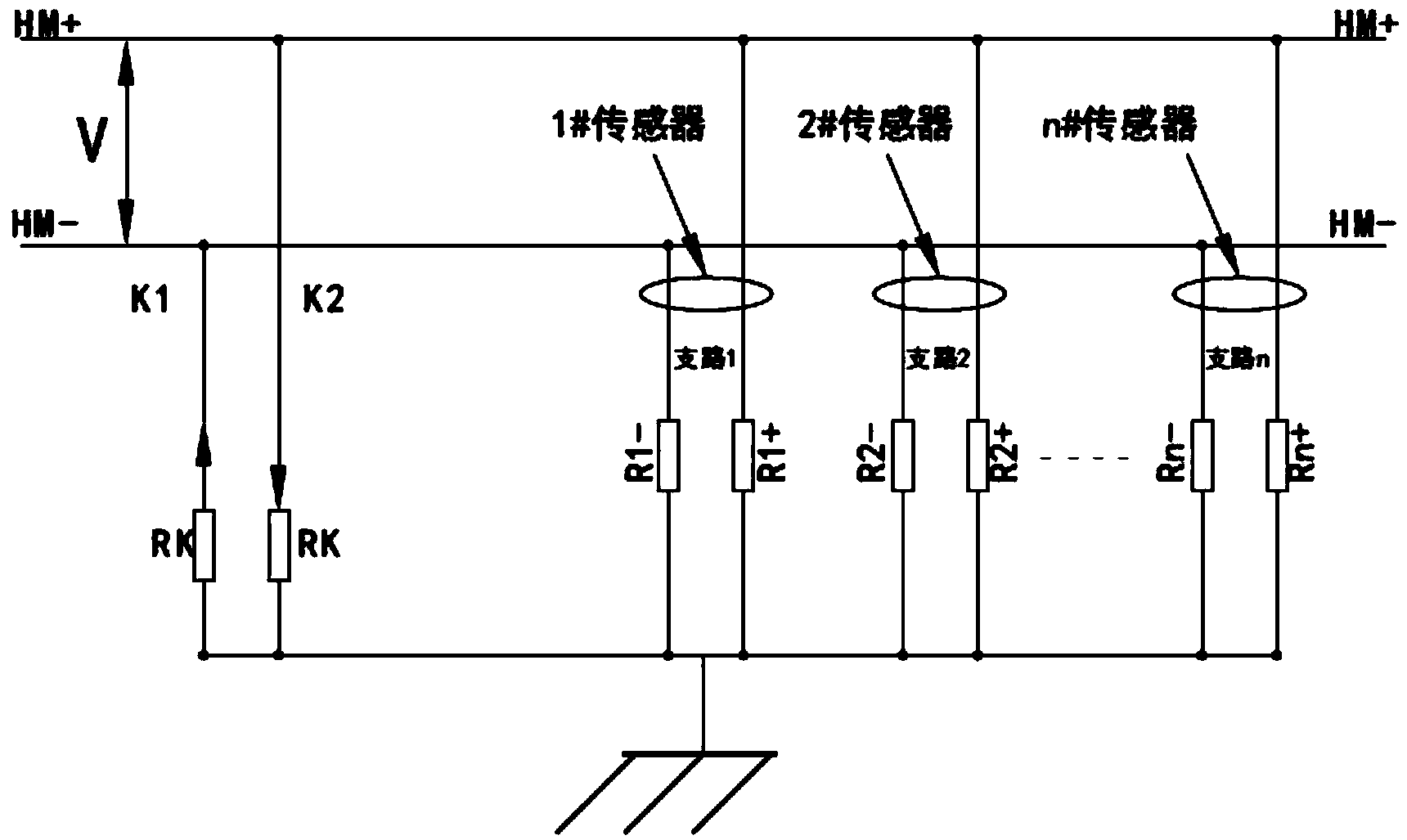

[0018] A 240V high-voltage DC insulation monitoring system. The system adopts a balanced and unbalanced bridge compatible detection method to isolate and monitor the ground voltage of the positive and negative bus bars in real time, and measure the insulation resistance of the bus bar; when the bus bar insulation drops, it sends out an alarm signal and starts Branch inspection, at the same time put branch power resistor RK in the bus, and send branch inspection command to the intelligent leakage current sensor to find the grounding branch through the RS485 bus; The intell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com