Hearing aid with physical sound guide module

A hearing aid and sound guiding technology, applied in the field of medical devices, can solve problems such as ear plugging, and achieve the effect of reducing high-frequency impurities, improving clarity, and clear speech

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

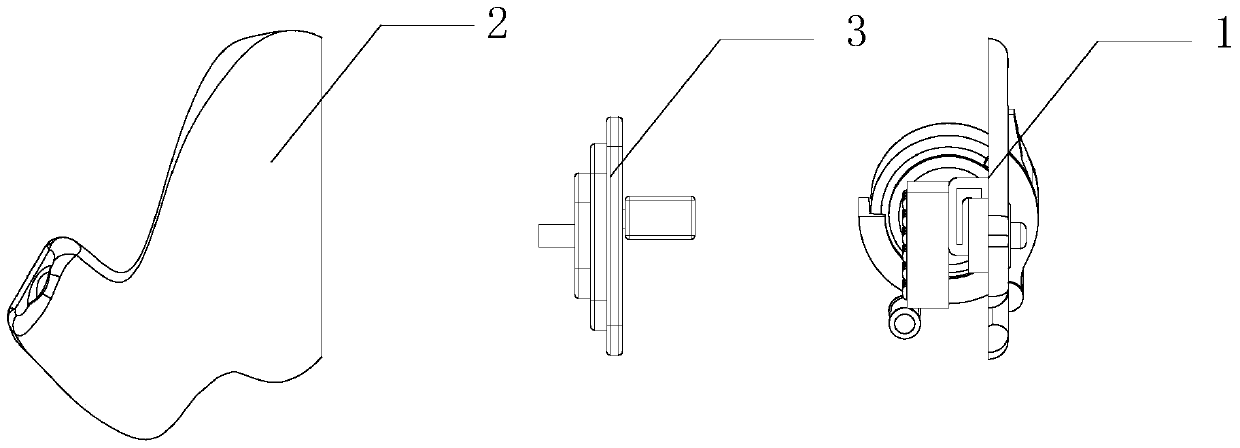

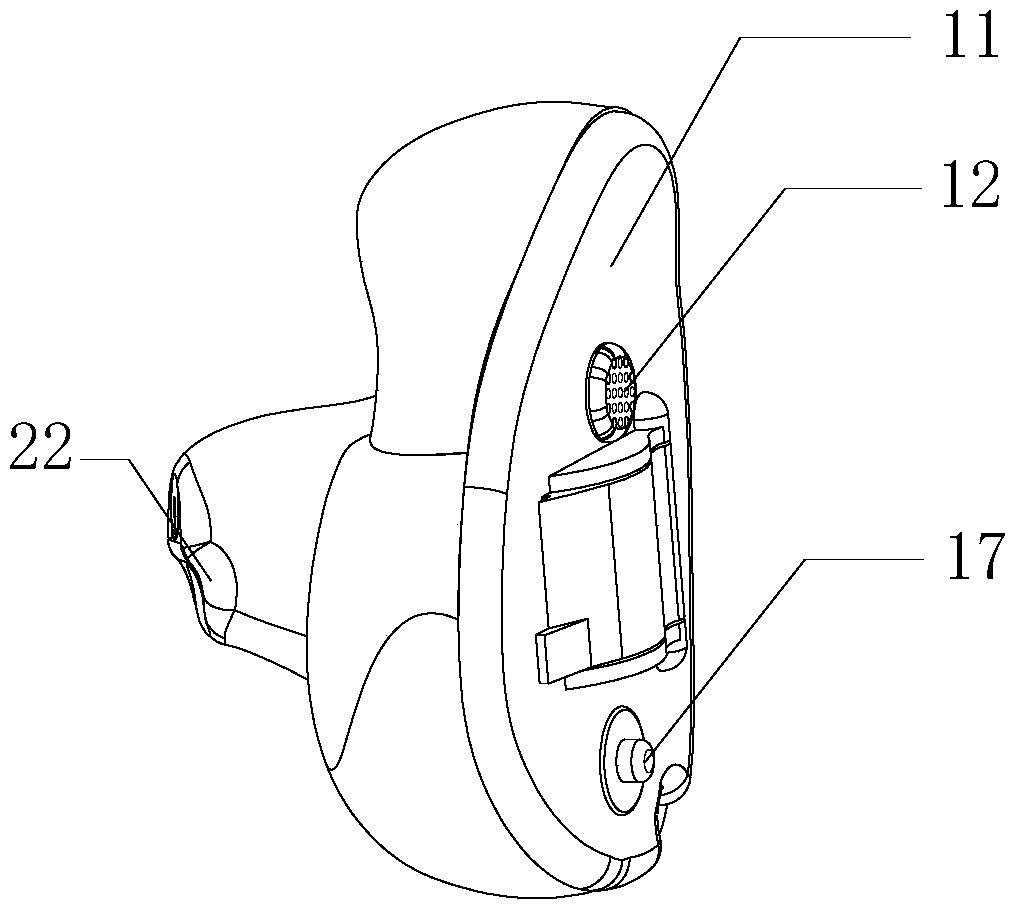

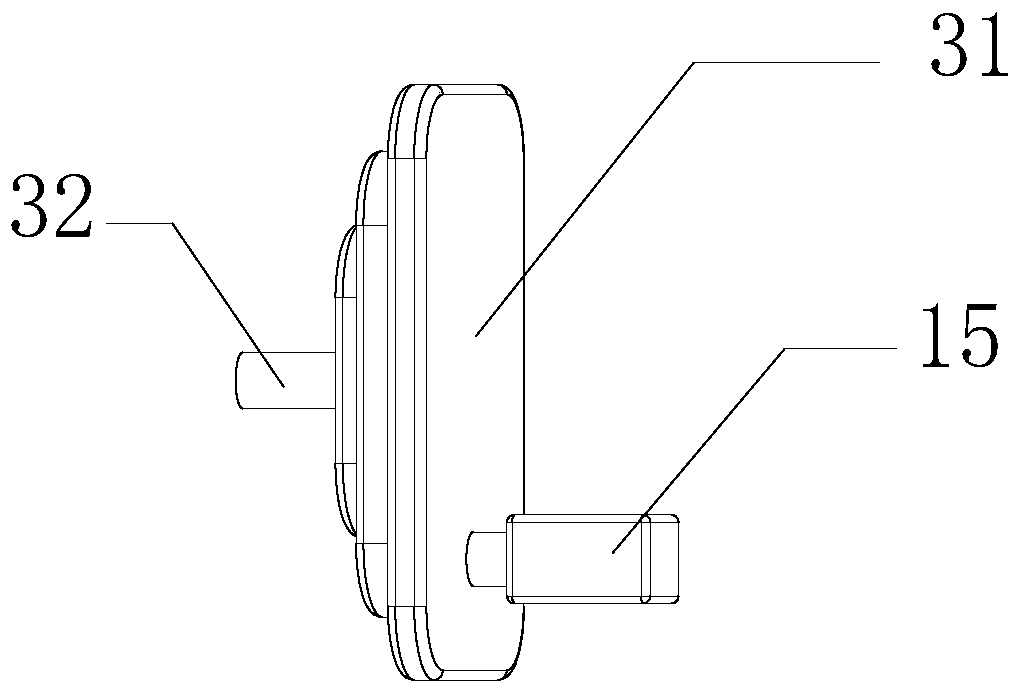

[0032] A hearing aid with a physical sound guide module, the hearing aid includes a custom shell 2 and a panel device 1 covering the opening outside the custom shell 2, an acoustic inner cavity 21 is formed inside the custom shell 2, and the panel device 1 includes a panel 11 and The sound collection hole 12, the microphone 13, the circuit board 14, the digital signal processing chip, the receiver 15, and the power supply unit 16 installed on the panel 11, and the hearing aid also includes a device installed in the acoustic inner cavity 21 for transmission to the ear canal. The sound guide module 3 of the sound signal; the sound guide module 3 includes more than one set of sound guide units stacked in sequence, and each set of sound guide units includes an ear mold support plate 31 and a sound guide tube 32 installed on the ear mold support plate 31 The sound guide tube 32 of each group of sound guide units spirals into a curved and meandering shape on its corresponding ear mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com