Chain saw

A technology of chain saws and sprockets, which is applied in the field of chain saws, and can solve the problems that the maximum output of the motor cannot be fully ensured, the clutch device cannot work, and hinder the large-scale motor, so as to improve reliability, shorten braking time, and reliably deviate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below based on the drawings.

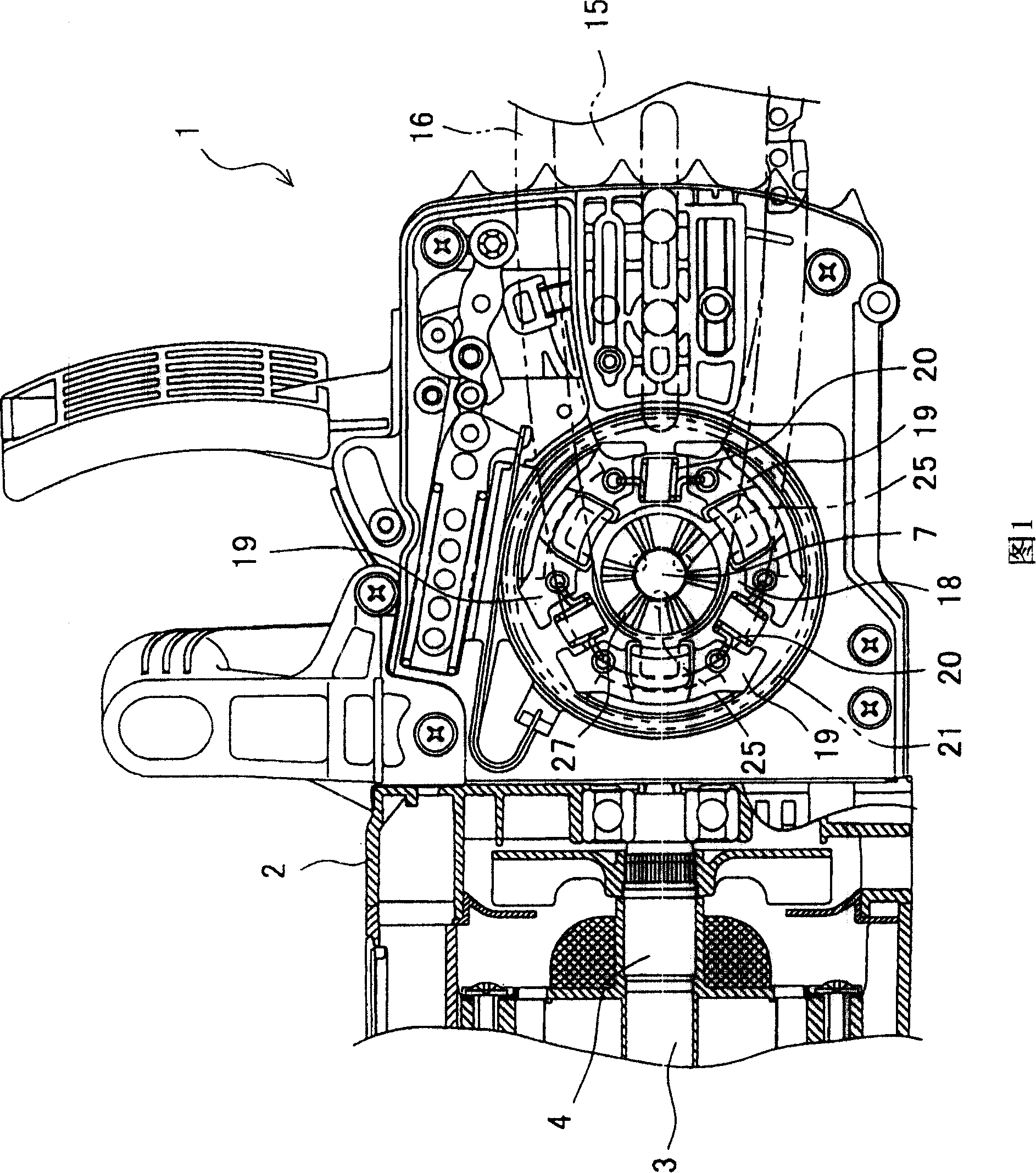

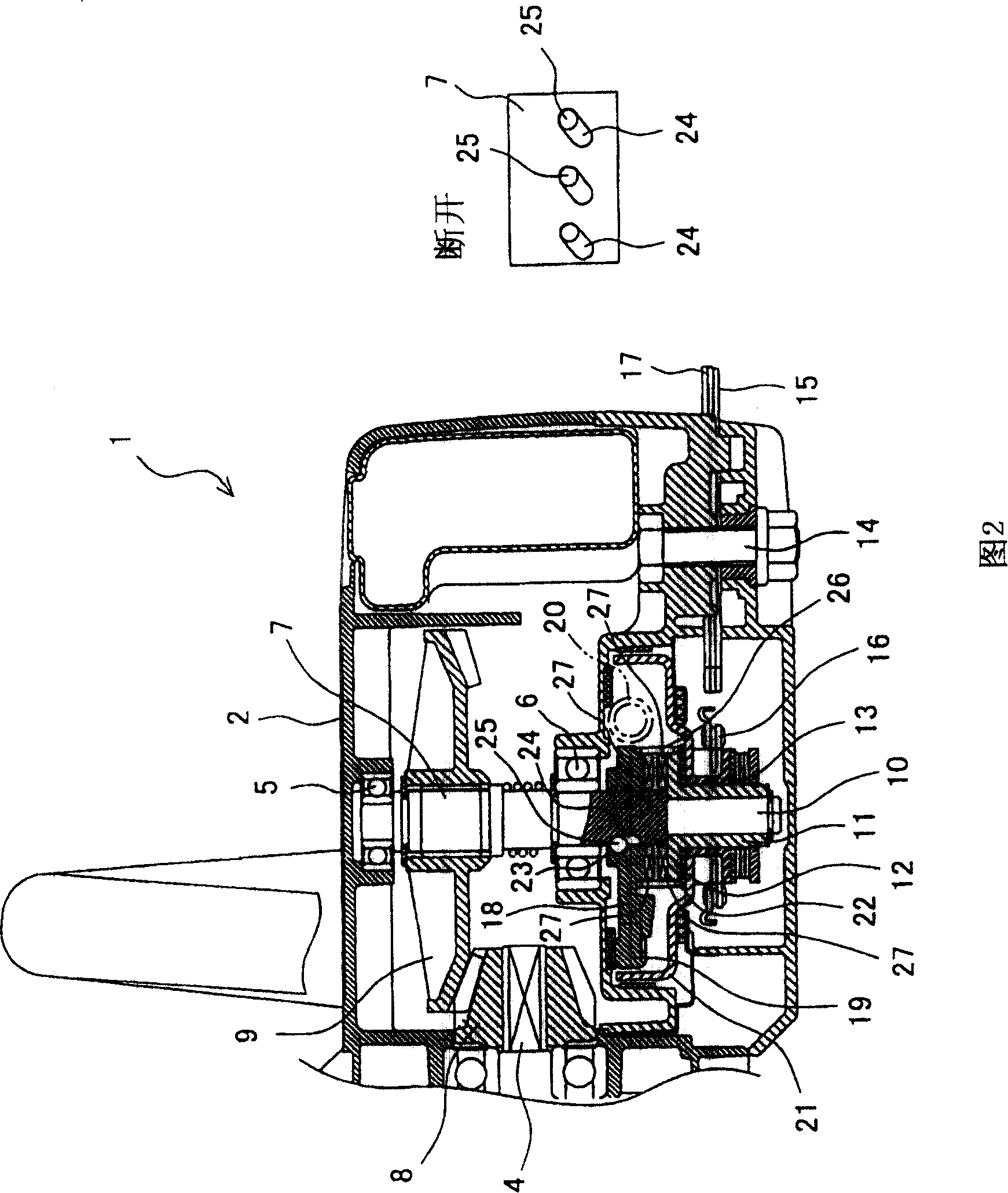

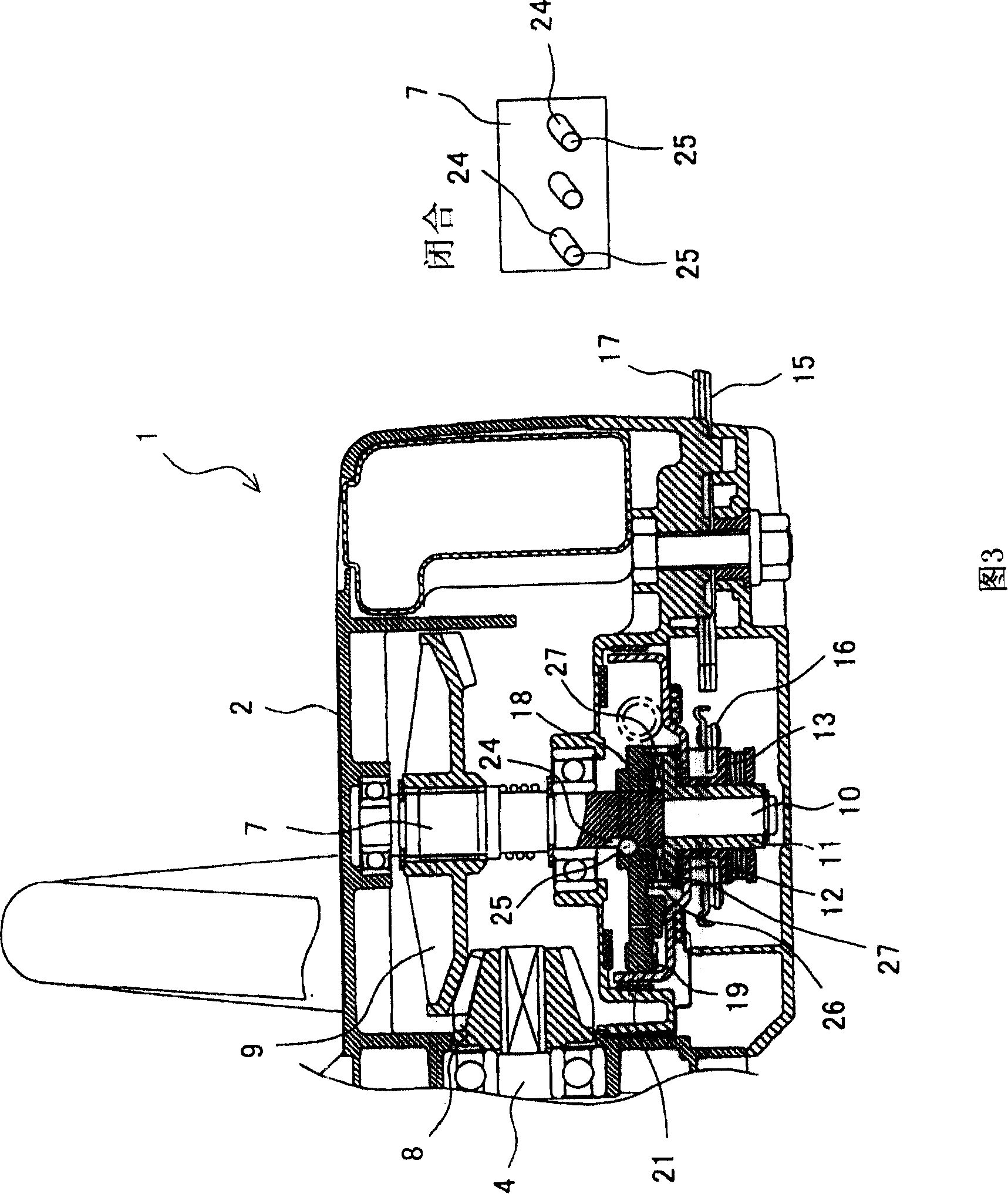

[0025] FIG. 1 is a partial vertical cross-sectional view showing an example of a chain saw, and the right side figure in FIG. 2 is a partial horizontal cross-sectional view. In the chain saw 1, the electric motor 3 is accommodated in the casing 2 facing forward (the right side in FIGS. The rotation of the output shaft 4 can be transmitted to the main shaft 7 by engaging the bevel gears 8 , 9 respectively fixed to the output shaft 4 and the main shaft 7 in a transverse direction perpendicular to the output shaft 4 . In addition, the end portion of the main shaft 7 on the opposite side to the bevel gear 9 protrudes laterally through the housing 2, and a cylindrical cam 11 that is independently rotatable is mounted on the protruding end portion 10, and the cam 11 is located on the inside. A flange 12 is extended (on the ball bearing 6 side), and a sprocket 13 integrally rotatable is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com