A kind of porous ceramic slow flow piece and watering joint with it

A technology of porous ceramics and water flow parts, which is applied in the field of porous ceramic slow flow parts and watering joints, and can solve problems such as death, potted plants replenishing water, potted plants withered, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

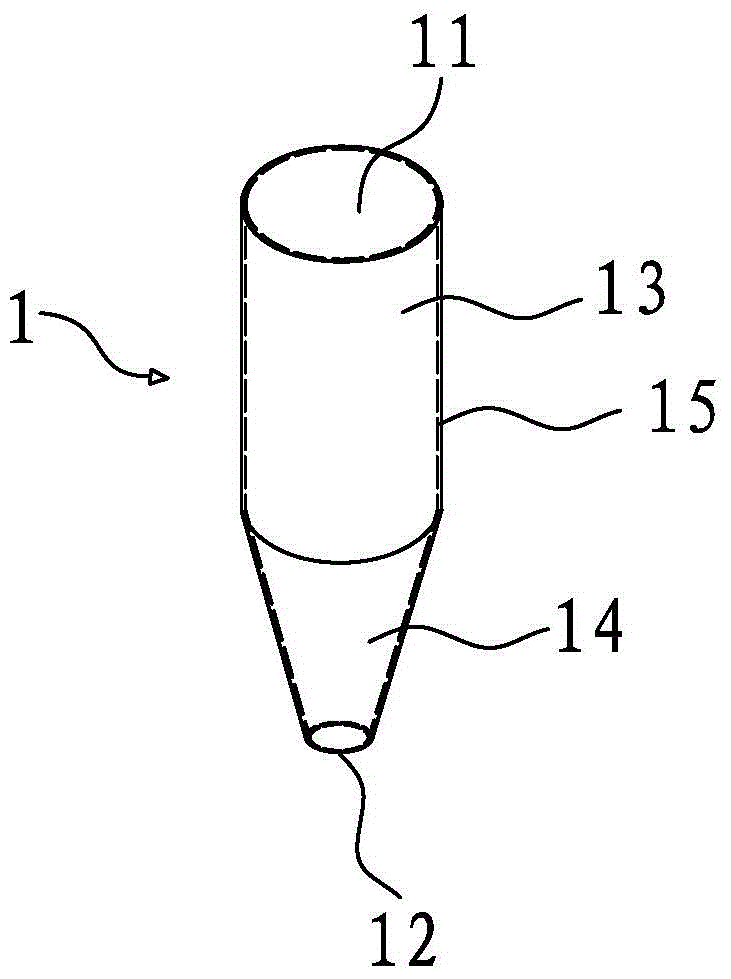

[0024] Such as figure 1 As shown, the present invention discloses a porous ceramic slow-flow member, which includes a porous ceramic body and a wax layer 15, wherein:

[0025] The porous ceramic body has a top surface 11 , a bottom surface 12 and a peripheral surface 13 . A wax layer 15 is coated on the peripheral surface 13 of the porous ceramic body. The wax layer 15 is a paraffin wax layer.

[0026] In this embodiment, the upper part of the porous ceramic body is cylindrical. The lower part 14 of the porous ceramic body is in the shape of an inverted cone or an inverted pyramid. In this embodiment, the lower part 14 is in the shape of an inverted cone. The height of the lower part 14 is determined according to the water outlet speed.

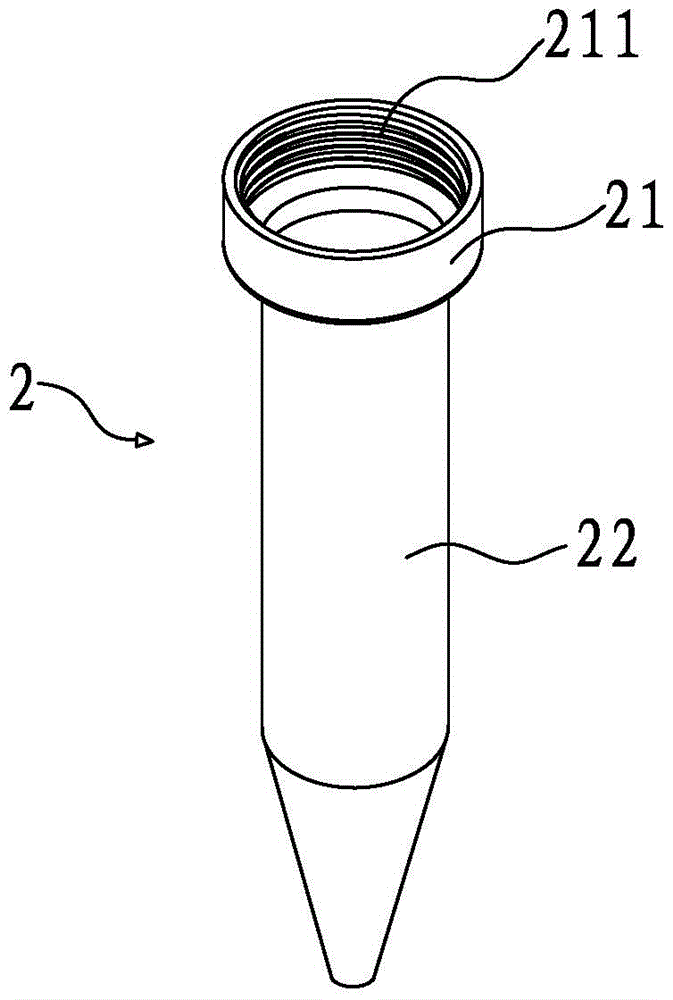

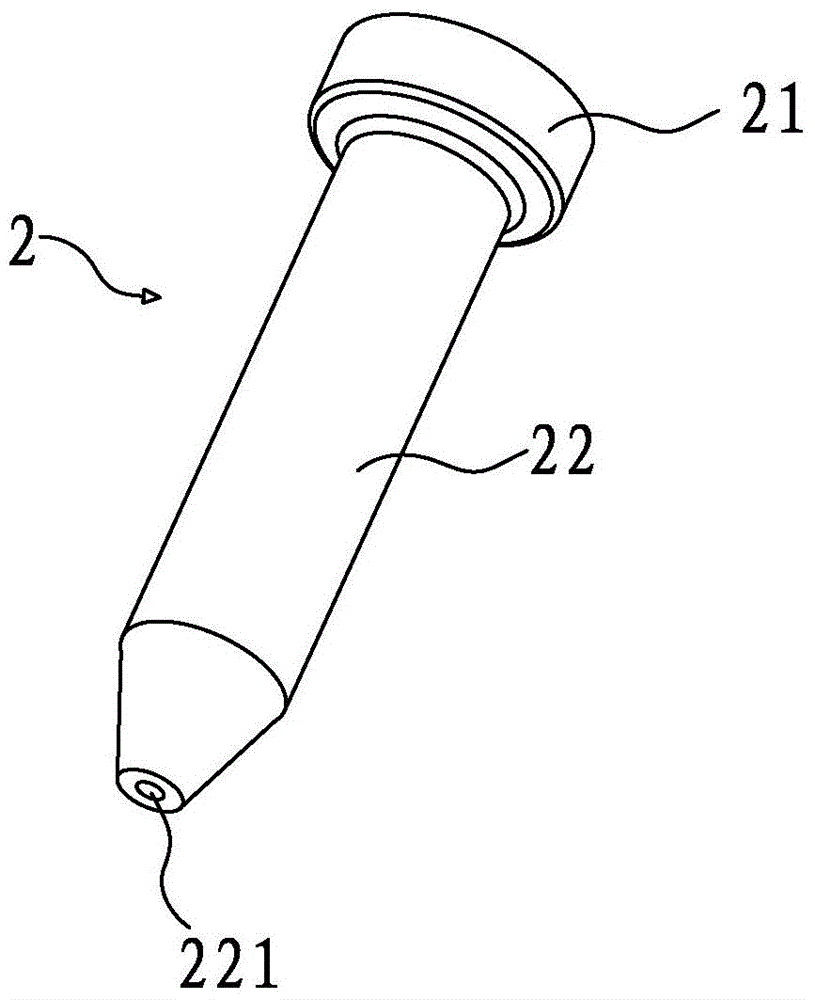

[0027] Such as figure 2 , 3 As shown in , 4, the present invention also discloses a watering joint with a porous ceramic slow-flow member, which includes a centrally connected joint cylinder and the above-mentioned porous ceramic slow-flo...

Embodiment 2

[0036] The differences between this embodiment and Embodiment 1 are:

[0037] The porous ceramic of the porous ceramic slow flow part is made of the following components in parts by weight: 1 part of base material, 0.03 parts of binder and 1.1 parts of deionized water; the base material includes the following components in parts by weight : 1 part of alumina, 3 parts of cordierite clinker, 0.3 part of vermiculite powder, 3 parts of diatomite, 2 parts of kaolin, 3 parts of attapulgite and 8 parts of woody activated carbon; Minutes: 1 part of PVA, 4 parts of CMC, 0.8 part of gum arabic.

[0038] Preparation:

[0039] Dissolve PVA in deionized water to obtain solution A, dissolve CMC in deionized water to obtain solution B, heat and dissolve gum arabic in deionized water to obtain solution C, and dissolve alumina, cordierite clinker, vermiculite powder, diatomaceous earth , kaolin, attapulgite, woody activated carbon and three solutions of A, B and C plus deionized water for ba...

Embodiment 3

[0041] The differences between this embodiment and Embodiment 1 are:

[0042] The porous ceramic of the porous ceramic slow flow part is made of the following components in parts by weight: 1 part of base material, 0.06 parts of binder and 1 part of deionized water; the base material includes the following components in parts by weight : 1 part of alumina, 2 parts of cordierite clinker, 3 parts of vermiculite powder, 2 parts of diatomite, 3 parts of kaolin, 4.6 parts of attapulgite and 2 parts of woody activated carbon; Minutes: 1 part of PVA, 2 parts of CMC, 3.6 parts of gum arabic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com