Remote pneumatic feeding and weighing feeder

A feeding machine and weighing technology, applied in conveyors, feeders, automatic feeding/discharging weighing equipment, etc., can solve the problem of increasing user investment costs, climbing of feeding pipelines, complex machine structure, etc. problems, to achieve the effect of saving manpower, reducing labor intensity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

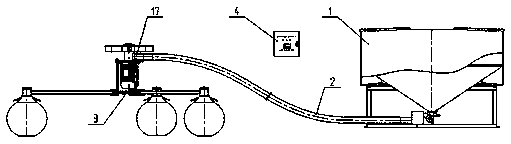

[0017] like Figure 1-6 As shown, the remote pneumatic feed meter feeding machine includes a weight feed box 1, a feed pipeline 2, a pneumatic throwing machine 3 and a control box 4, which are connected to the feed output pipe 12 of the weight feed box 1 The feeding pipeline 2, one end of the feeding pipeline 2 is connected to the receiving output pipe 13 of the weighing feed box 1, the other end of the feeding pipeline 2 is connected to the feeding interface pipe 17 of the pneumatic throwing machine 3, and the wiring in the control box 4 The terminals are respectively connected to the connecting terminal 16 of the weighing feeding box 1 and the motor of the pneumatic throwing machine 3, and the input terminal of the control box 4 is connected to the three-phase power grid to form a remote pneumatic feeding meter re-throwing feeder as a whole.

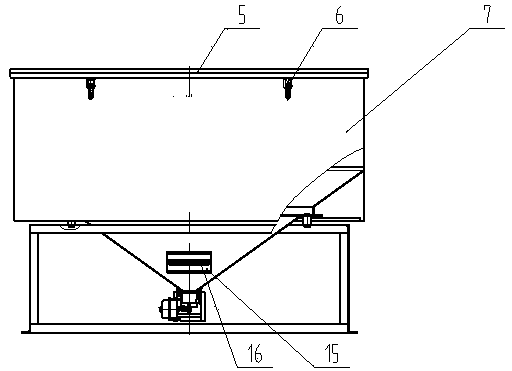

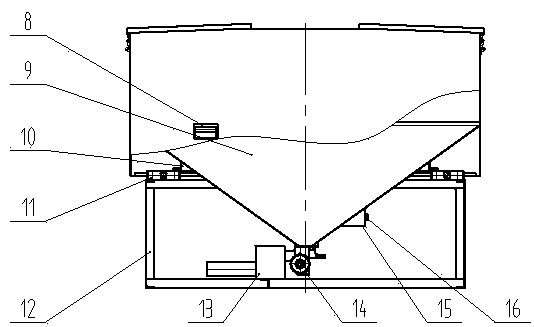

[0018] In the remote pneumatic feeding meter weighing feeder of the present invention, the weighing feeding box 1 includes a box cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com