High voltage component and air purifier

A technology of high-voltage components and tungsten wire, which is applied in the field of air purification, can solve the problems of insufficient isolation, difficulty in designing a complete seal, and discharge of tungsten wire, so as to improve the insulation level, weaken the high-voltage discharge phenomenon, and stabilize the purification performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

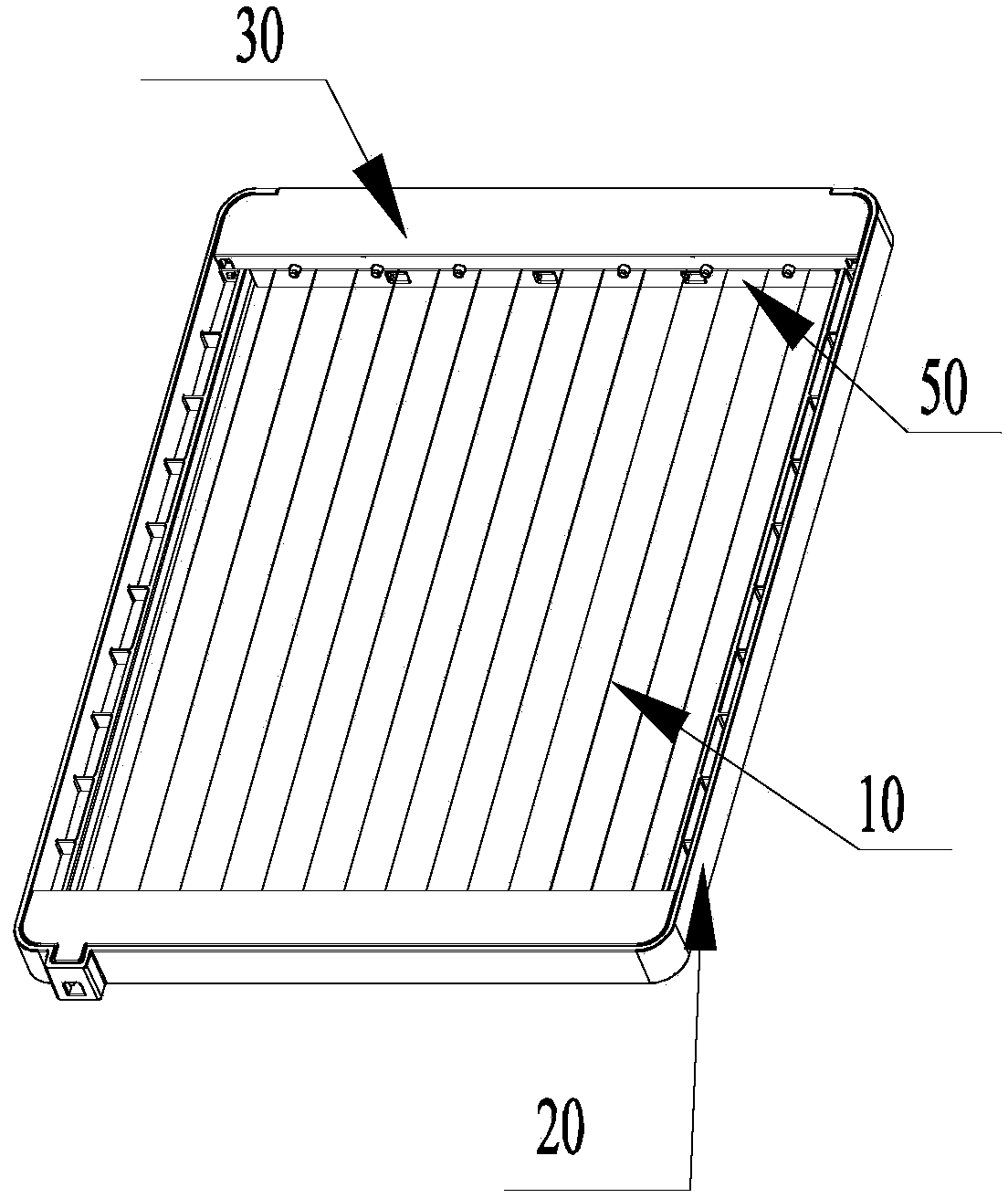

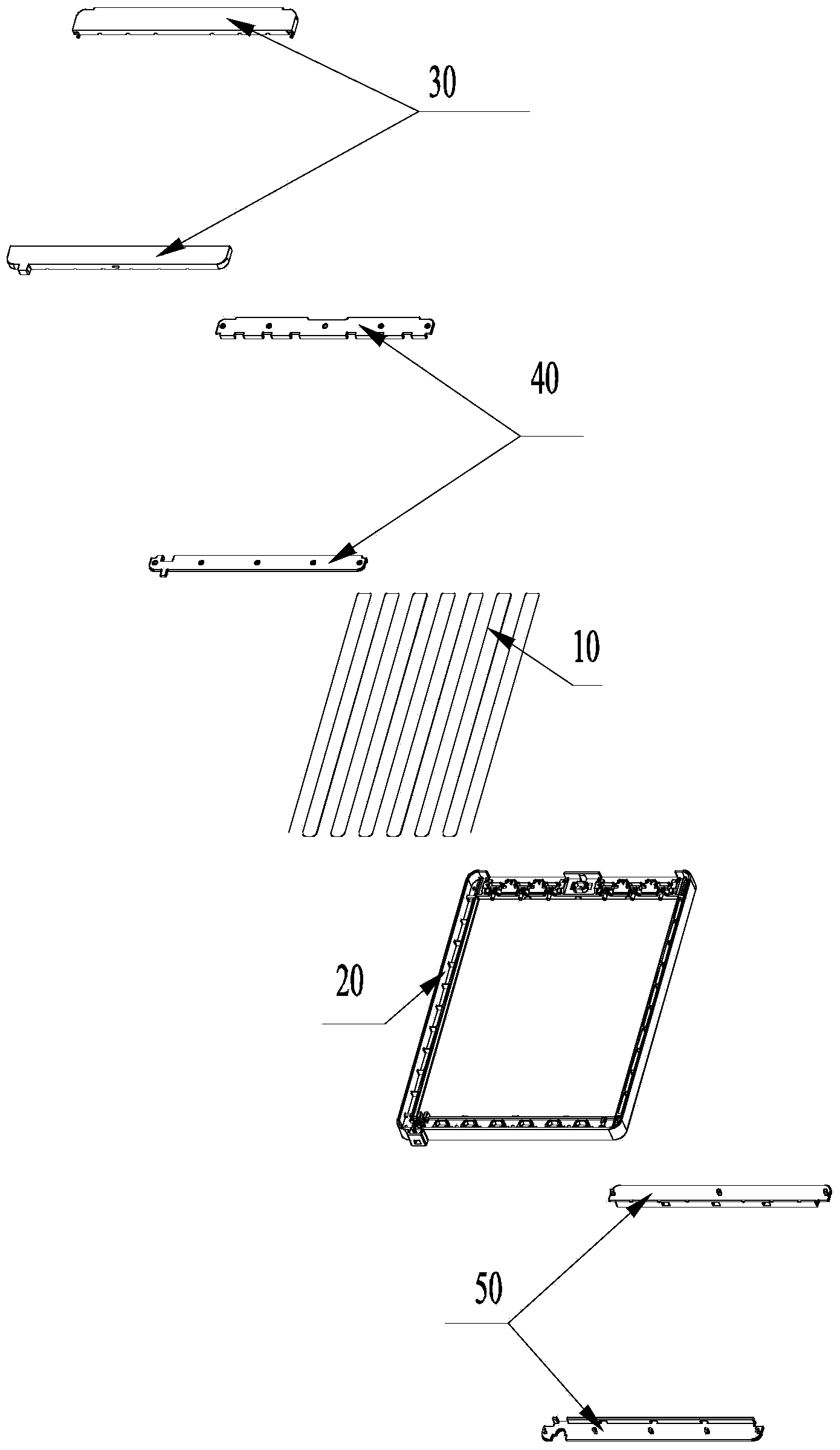

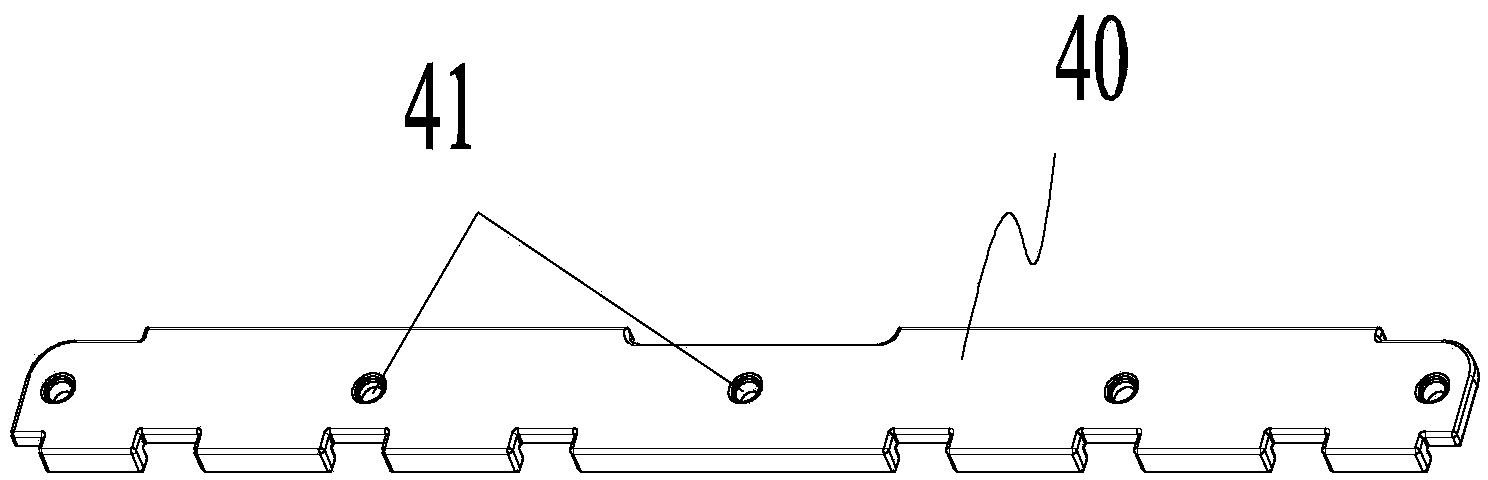

[0029] Such as figure 1 and figure 2 As shown, the high-voltage assembly according to the present invention includes a tungsten wire 10, a tungsten wire mounting frame 20 and a cover plate 30, the tungsten wire mounting frame 20 has a tungsten wire fixed end, and the tungsten wire 10 is fixed on the tungsten wire fixed end and passes through the cover plate 30 , the high-voltage assembly further includes a first insulating pad 40 , and the first insulating pad 40 covers the side of the cover plate 30 facing the tungsten wire mounting frame 20 . In the present invention, by covering the first insulating pad 40 on the side of the cover plate 30 facing the tungsten wire mounting frame 20, compared with the prior art, the insulation between the tungsten wire 10 and the outside world is changed from a single cover plate 30 isolation to a cover plate 30 and T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com