Neutral beam injection gradient pole voltage-dividing power supply high voltage leading-out wire terminal

A high-voltage lead-out wire, neutral beam technology, applied in the direction of lead-in/through-type insulators, etc., can solve the problems of large volume and weight, increase the manufacturing cost of gradient polar voltage divider power supply, etc., and achieve small size, light weight, and insulation level. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

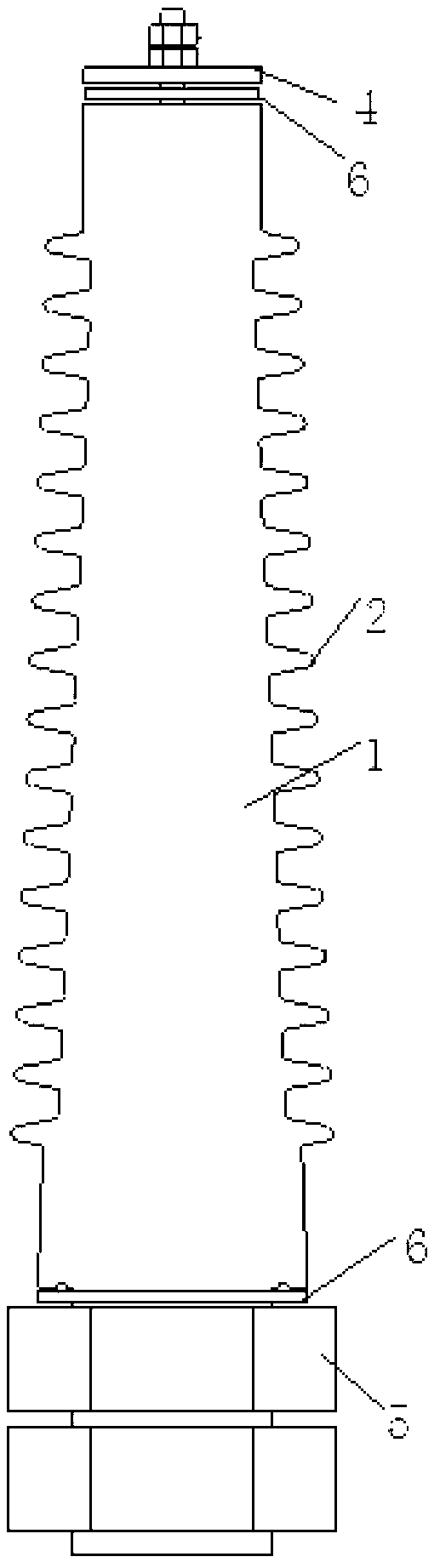

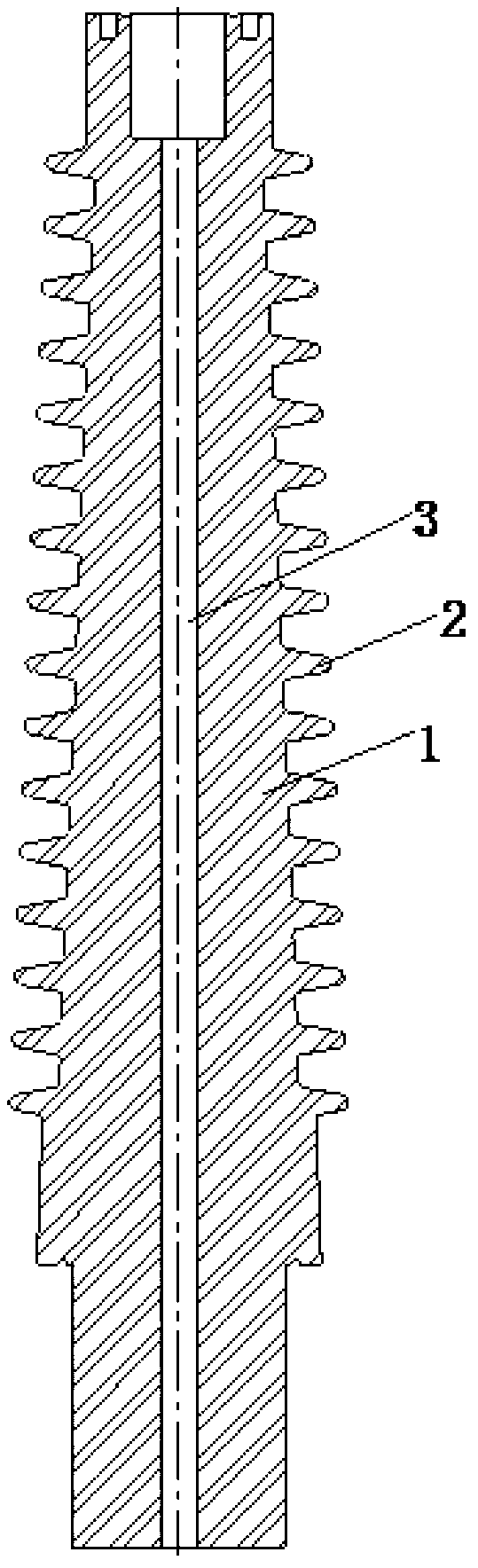

[0010] like figure 1 , 2 . As shown in 3, a neutral beam injection gradient pole voltage dividing power supply high-voltage lead wire terminal includes a sleeve 1, and the sleeve 1 is made of a cylindrical polytetrafluoroethylene material, and the sleeve 1 The periphery is cut into a protruding annular piece 2 to increase the surface insulation length. A central hole 3 leading to the top is opened from the center of the bottom of the bushing 1, and the internal high-voltage lead wire of the gradient pole voltage divider is drawn out from the central hole 3. The top of the bushing 1 is fixed with a top cover 4 for fixing the high-voltage lead wire. The lower part of the bushing 1 is provided with an external thread, and the lower part of the bushing 1 is screwed with a polytetrafluoroethylene nut 5 through the external thread. The gas enters the oil tank through the center hole 3 of the casing and the insulating oil flows out from the center hole 3 of the casing 1. Rubber seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com