Transformer with built-in cabin used for wind power generation

A transformer, built-in technology, applied in transformer/inductor casing, transformer/inductor cooling, transformer/inductor magnetic core, etc., can solve the problem of poor sealing performance of transformers, easy pollution of the environment, poor coordination and reliability, and increased line loss and other problems, to achieve the effect of convenient and reliable connection, safe operation and stable electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The concrete technical scheme of the present invention will be further described below in conjunction with embodiment:

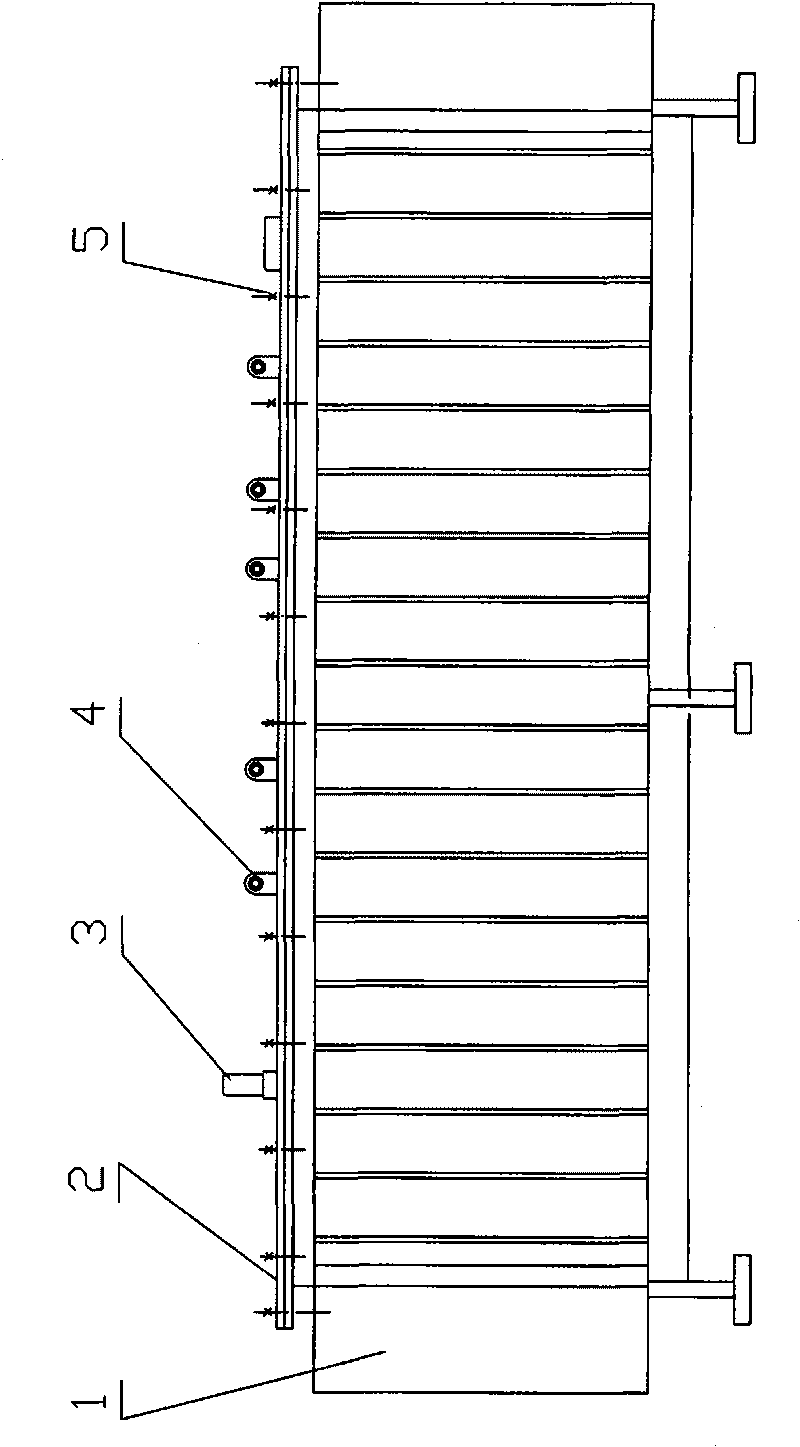

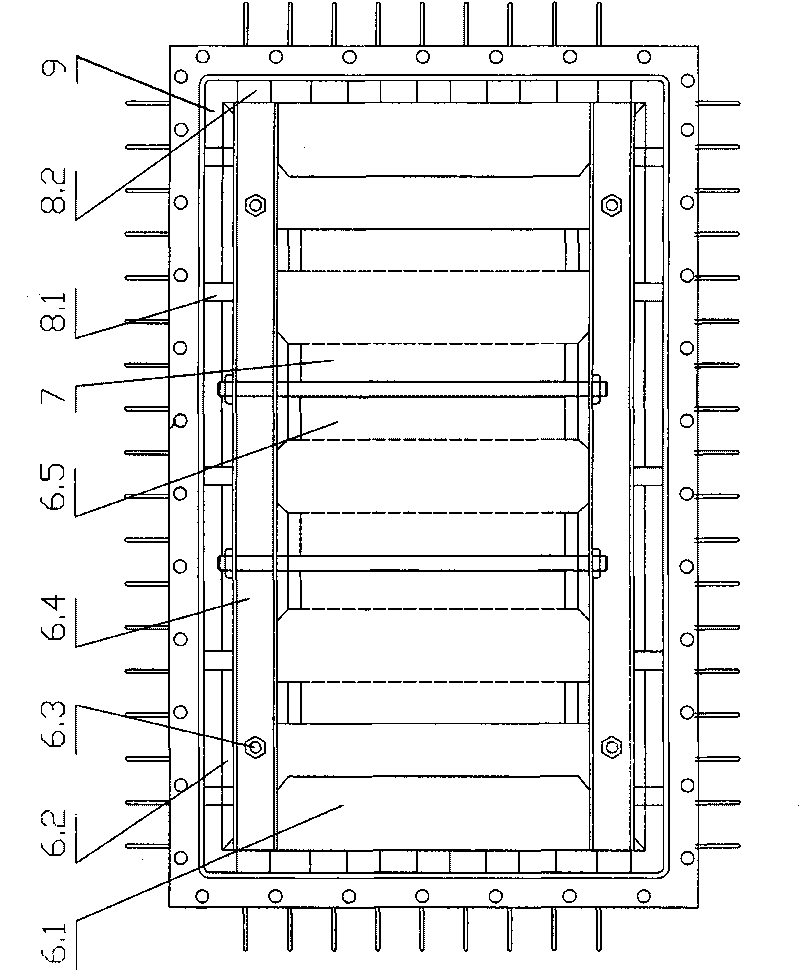

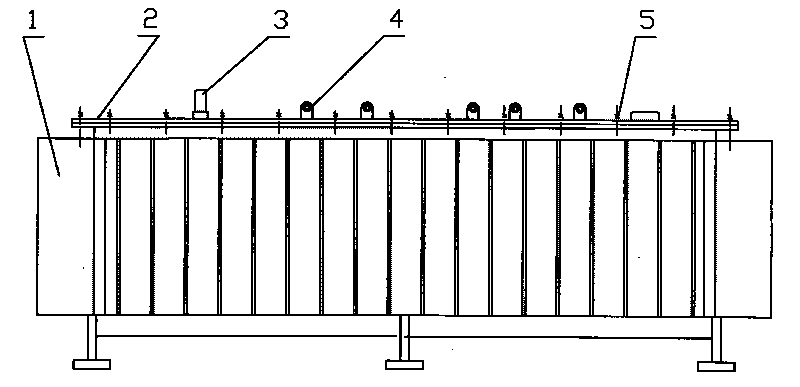

[0030] Such as Figure 1 ~ Figure 2 As shown, the built-in transformer for wind power generation includes a corrugated oil tank 1, an iron core, a three-phase winding 7, an external lead joint 4 and an insulation system, wherein

[0031] Corrugated oil tank 1: the bottom is made of thicker steel plate bent into a groove shape and welded; the upper part is cut and welded with angle steel to form a square frame, and the surrounding is made of thicker steel plate bent and welded into strips of angular cross-section, and the three are combined into four sides A box with an opening, a lower groove, and an upper opening; corrugated sheets are welded on the four sides where there are openings. After all welding is completed, a pressure leak test is carried out, and the qualified transfer to the painting process.

[0032] Tank cover 2: It is made of thicker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com