Pipe blank forming mold structure of double-wall corrugated pipe

A double-wall corrugated pipe and tube blank forming technology, which is applied in the field of plastic double-wall corrugated tube blank forming mold structure, can solve the problems of increased difficulty and material consumption, easy damage, easy deformation and cracking, etc. Easy to deform and break, good tensile strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

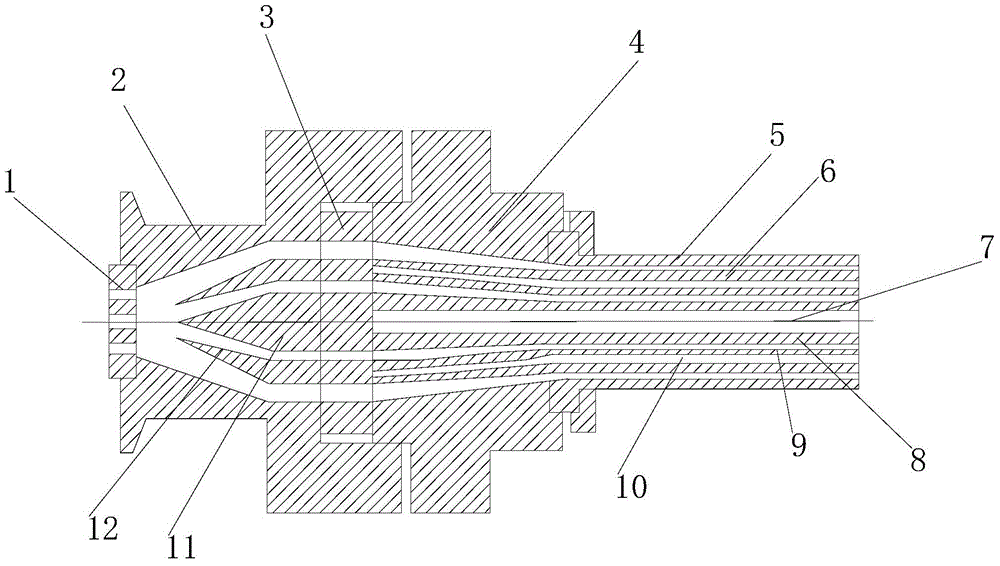

[0010] refer to figure 1 , the pipe blank forming mold structure of the double-wall bellows, including the plug 2 and the middle sleeve 4, the rear end of the plug 2 is provided with a groove, the front end of the middle sleeve is provided with a protrusion, the plug 2 and the middle sleeve 4. Fitting and connecting to form a mold body, the groove of the plug 2 is provided with a splitter cone support 3, the front end of the plug 2 is fixedly connected with a porous plate 1, and the inner wall of the plug 2 is symmetrically arranged from the inside to the outside on the central axis Melt flow channel cavity 11 and outer wall melt flow channel cavity 12, the inner central axis of the middle sleeve 4 is symmetrically provided with inner tube wall forming mandrel 8, outer tube wall forming mandrel 6, inner layer Pipe wall forming die 9 and outer layer pipe wall forming die 5.

[0011] The center of the middle sleeve 4 is also provided with a central hole 7 for placing a heater. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com