Plastic smoke box automatic lapping device

A technology of a lap joint device and a power device, which is applied in the field of automatic lap joint devices for plastic smoke boxes, can solve the problems of reducing the economic benefit of enterprises, increasing the labor volume of workers, and increasing the cost and expenditure, and achieves the reduction of cost expenditure, labor volume, and improvement. The effect of production speed and quality speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

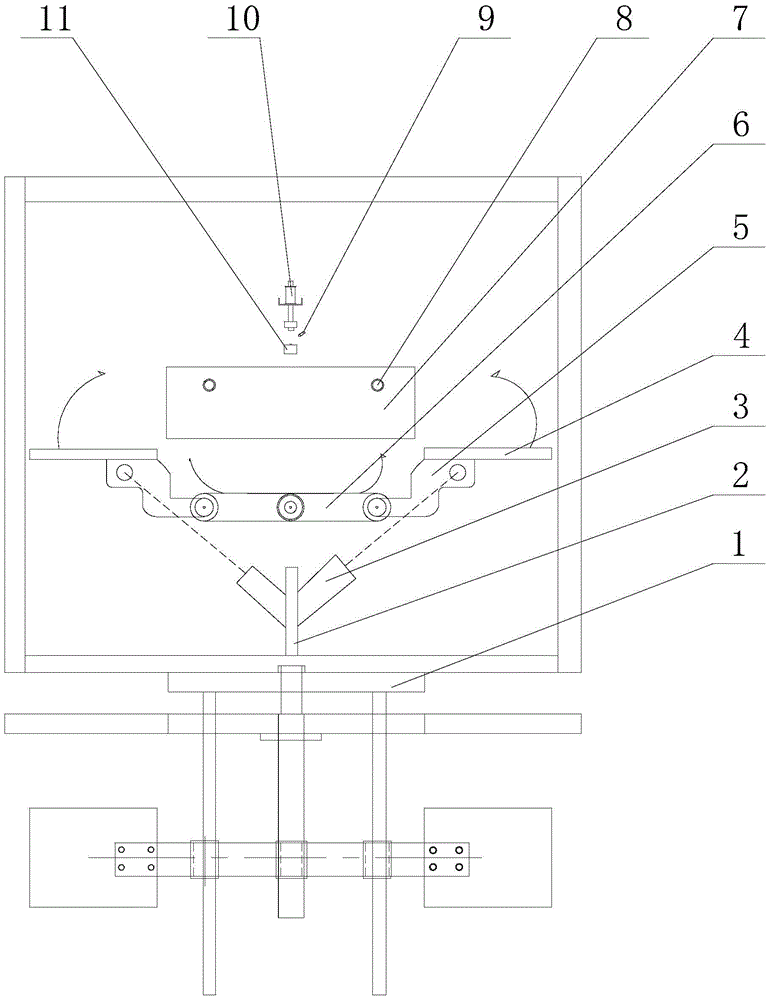

[0020] see figure 1 , the plastic cigarette box automatic lapping device described in a preferred embodiment of the present invention is suitable for a working platform 1 for cigarette box processing, including a turning power device installed on the working platform 1 and a central axis arranged above the turning power device 6. Both ends of the central axis 6 are symmetrically provided with moving tray devices, and a turning positioning device is provided directly above the middle position of the central axis 6 . A welding edge sealing device is arranged above the turning positioning device.

[0021] The turning power device includes a mounting frame 2 installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com