Motor car axle for low floor bogie

A bogie and low-floor technology, applied in axles, wheels, vehicle components, etc., can solve the problems of limited installation space for low-floor axles, fatigue cracks in bearing seats, and elevated height of the frame from the rail surface, etc., to achieve neutrality Good, easy to withdraw the wheel, the effect of height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

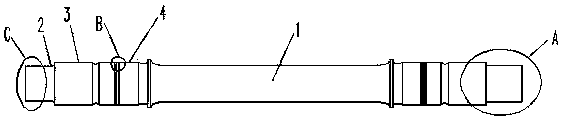

[0038] like figure 1 As shown, a motor vehicle axle for a low-floor bogie includes an axle body 1 , two journals 2 , two wheel seats 3 and two bearing seats 4 .

[0039] The shaft body 1 is preferably a cylinder, and two first frustums are preferably provided at both ends of the shaft body 1 , and the diameter of each first frustum gradually increases in a direction away from the shaft body 1 .

[0040] Two wheel bases 3 are arranged symmetrically at both ends of the shaft body 1 .

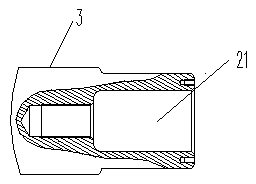

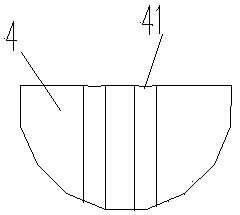

[0041] Each wheel base 3 is provided with a journal 2 on one side away from the shaft body 1 . like figure 2 and Figure 5 As shown, one of the journals 2 is provided with a gearbox installation interface 21 for connecting with the gearbox 6 . like Figure 4 and Figure 5 As shown, the other journal 2 is provided with a brake disc instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com