Universal joint connection device for sucker rod in inclined well section of surface-driven oil production screw pump well

A connecting device and universal joint technology, which is applied in the direction of drill pipe, drilling equipment, earthwork drilling and mining, etc., can solve the problems of not being able to bear tension but only being able to bear pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

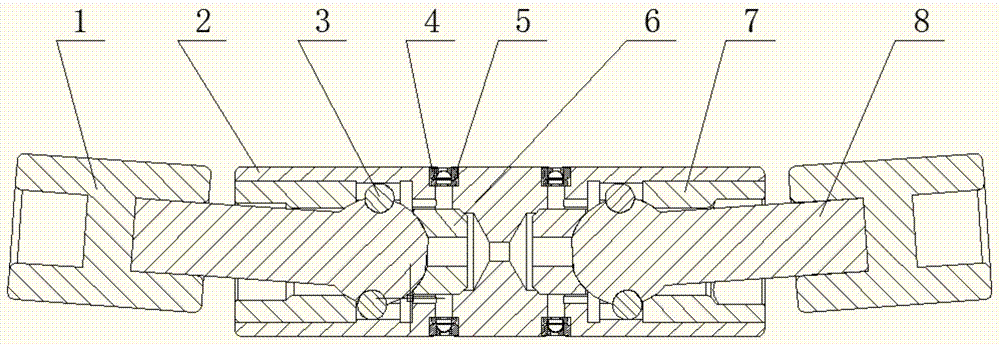

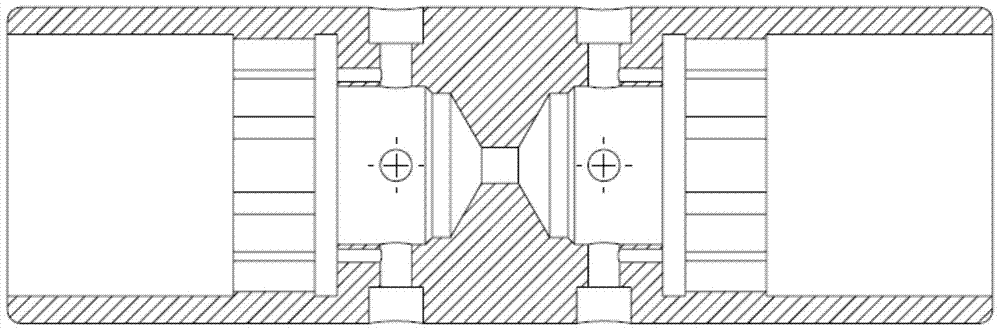

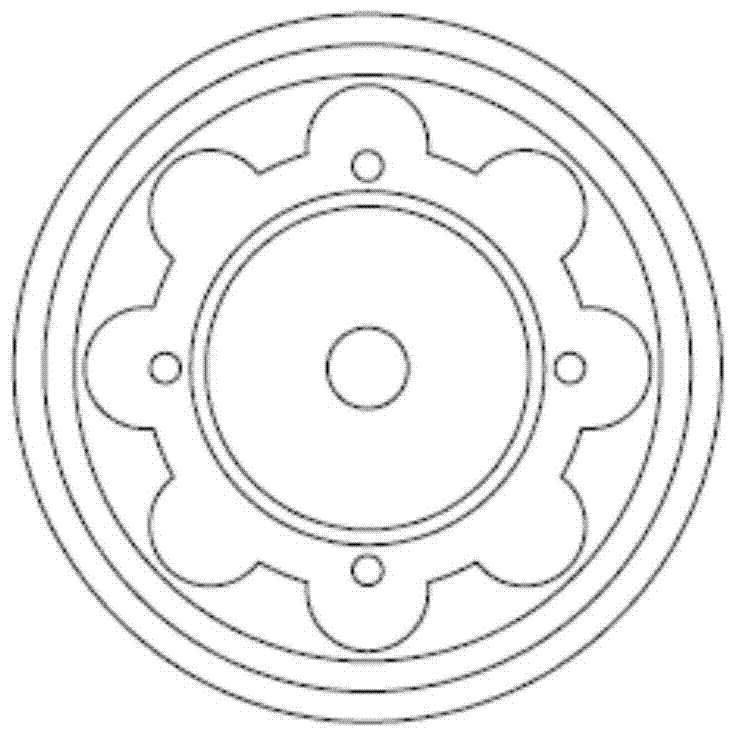

[0016] The present invention as figure 1 , figure 2 , image 3 , Figure 4 As shown, the two ends of the universal joint 2 are equipped with pressure bearing ball seats 6, the end of the deflection shaft 8 is connected with the box joint 1 through threads, and the spherical surface of the other end is passed through the pressure bearing ball seat 6 and the spherical pressure cap 7 axis. fixed on the universal joint 2, the steel ball 3 is installed in the semicircular arc groove on the inner circular surface of the end of the universal joint 2 and the ball socket on the spherical surface at the end of the deflection shaft 8, the steel ball 3 can be Axial movement in the semi-arc groove on the inner circular surface of the end of the joint joint 2, the deflecting shaft 8 transmits torque through the steel ball 3, and at the same time the deflecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com