Equal-modulus-gear fluid mechanism and engine employing same

A fluid mechanism and engine technology, which can be used in machines/engines, liquid fuel engines, combustion engines, etc., and can solve problems such as processing difficulties and seal wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

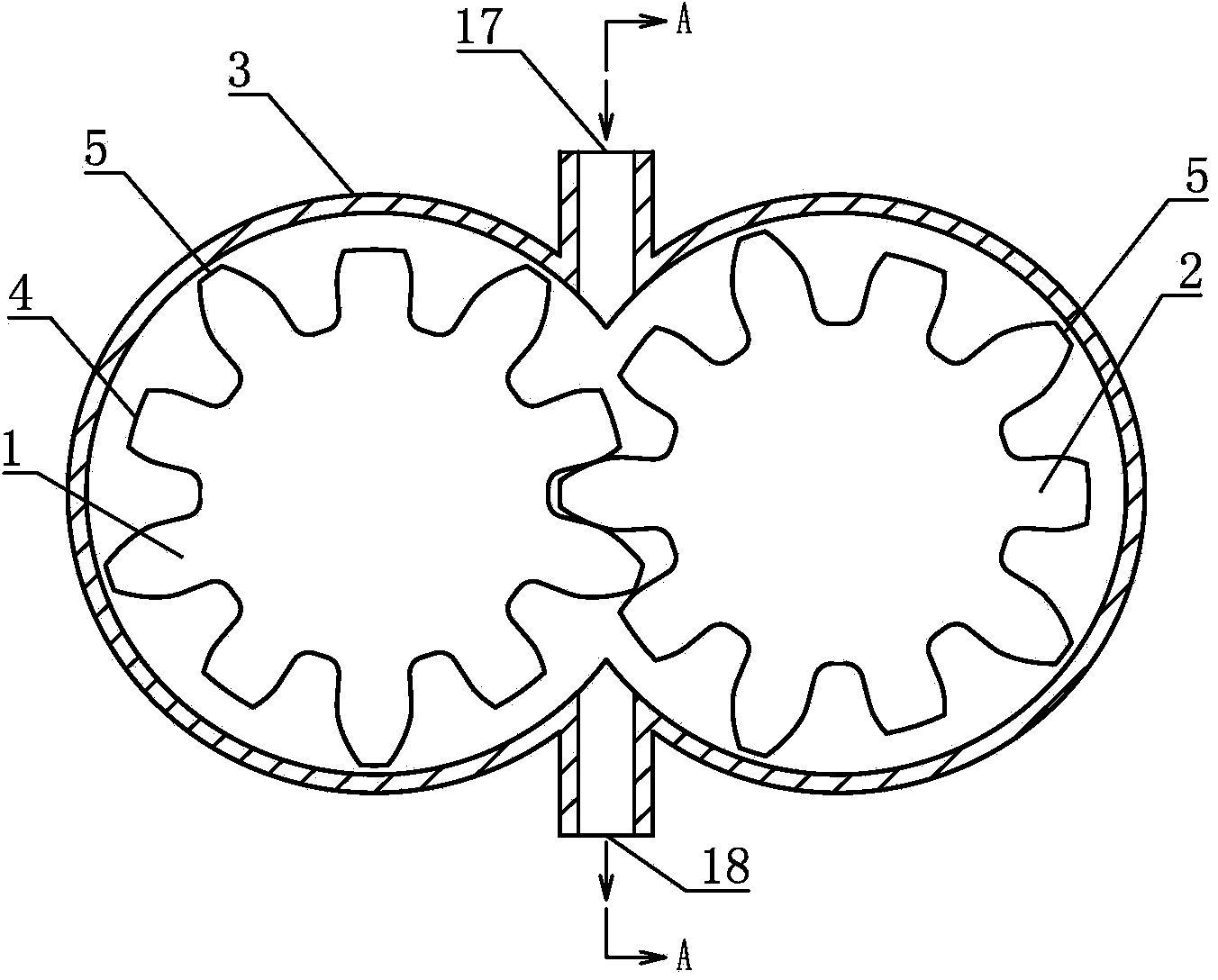

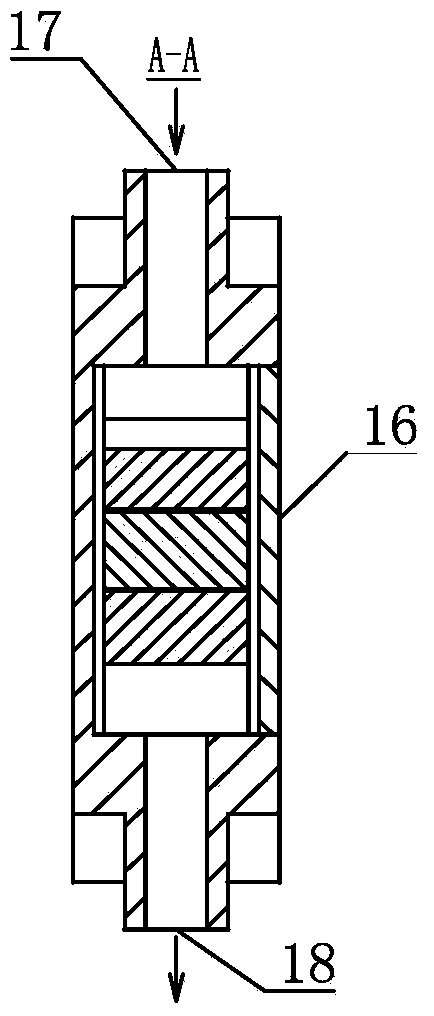

[0074] Such as Figure 1.1 with Figure 1.2 As shown, an equal-modulus gear fluid mechanism includes a gear A1 and a gear B2, the module of the gear A1 is the same as that of the gear B2, and the number of teeth of the gear A1 is the same as that of the gear B2 , a part of the teeth on the gear A1 is truncated to form a half tooth 4, a tooth that has not been truncated is defined as a full tooth 5, and a part of the teeth on the gear B2 is truncated to form a half tooth 4, The teeth that are not truncated are defined as full teeth 5, the gear A1 and the gear B2 are arranged in the double cylindrical cavity 3, and the gear A1 and the gear B2 are mutually meshed and rotated. A fluid inlet 17 is provided on the double-cylindrical cavity 3 , and a fluid outlet 18 is provided on the double-cylindrical cavity 3 .

[0075] As a changeable embodiment, optionally, a fluid inlet 17 is provided on the end sealing body 16 of the double cylindrical cavity 3; or on the double cylindrical c...

Embodiment 2

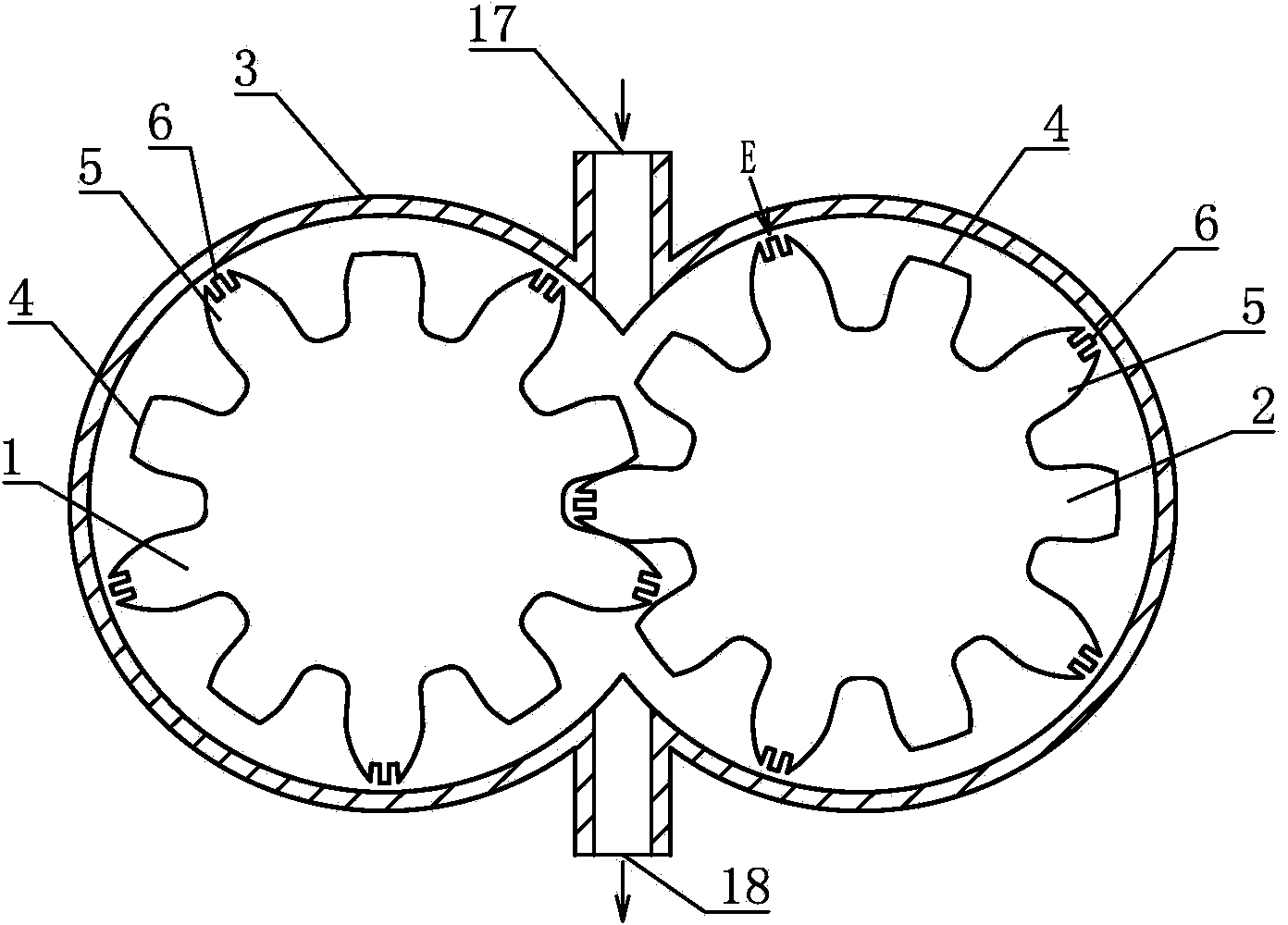

[0079] Such as Figure 2.1 with Figure 2.2 As shown, an equal-modulus gear fluid mechanism differs from Embodiment 1 in that a seal is provided on the tooth tops of the full teeth 5 on the gear A1 along the axis of rotation of the gear A1. Concave-convex resistance-increasing lines 6 , sealing concave-convex resistance-increasing lines 6 are provided on the tops of all teeth 5 on the gear B2 along the axis of rotation of the gear B2 .

[0080] As a changeable embodiment, it is also possible to set a sealing concave-convex resistance increasing line 6 on the tooth tip of the full tooth 5 on one of the gear A1 and the gear B2 along the axis of rotation of the gear. .

[0081] In the present invention, all embodiments can refer to this embodiment along the gear A1 and / or the gear B1 on the tooth top of the full tooth 5 on the gear A1 and / or on the gear B1 Sealing concave-convex resistance-increasing lines 6 are arranged in the axis direction of the rotation.

Embodiment 3

[0083] Such as Figure 3.1 with Figure 3.2 As shown, an equal-modulus gear fluid mechanism differs from Embodiment 1 in that a concave-convex resistance-increasing structure 7 is provided on the end surface of the gear A1.

[0084] As a changeable embodiment, at least one of the three of the end face of the gear A1, the end face of the gear B2 and the inner wall of the end sealing body 16 can be provided with the concave-convex resistance increase Structure 7.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap