Hot air dryer for textiles

A technology for hot air drying and textiles, which is applied in the directions of drying, dryer, drying gas arrangement, etc., can solve the problems of uneven installation of heating devices, affecting the quality of textiles, and whether textiles are dried, and achieves improved drying effect, Simple structure and the effect of increasing drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

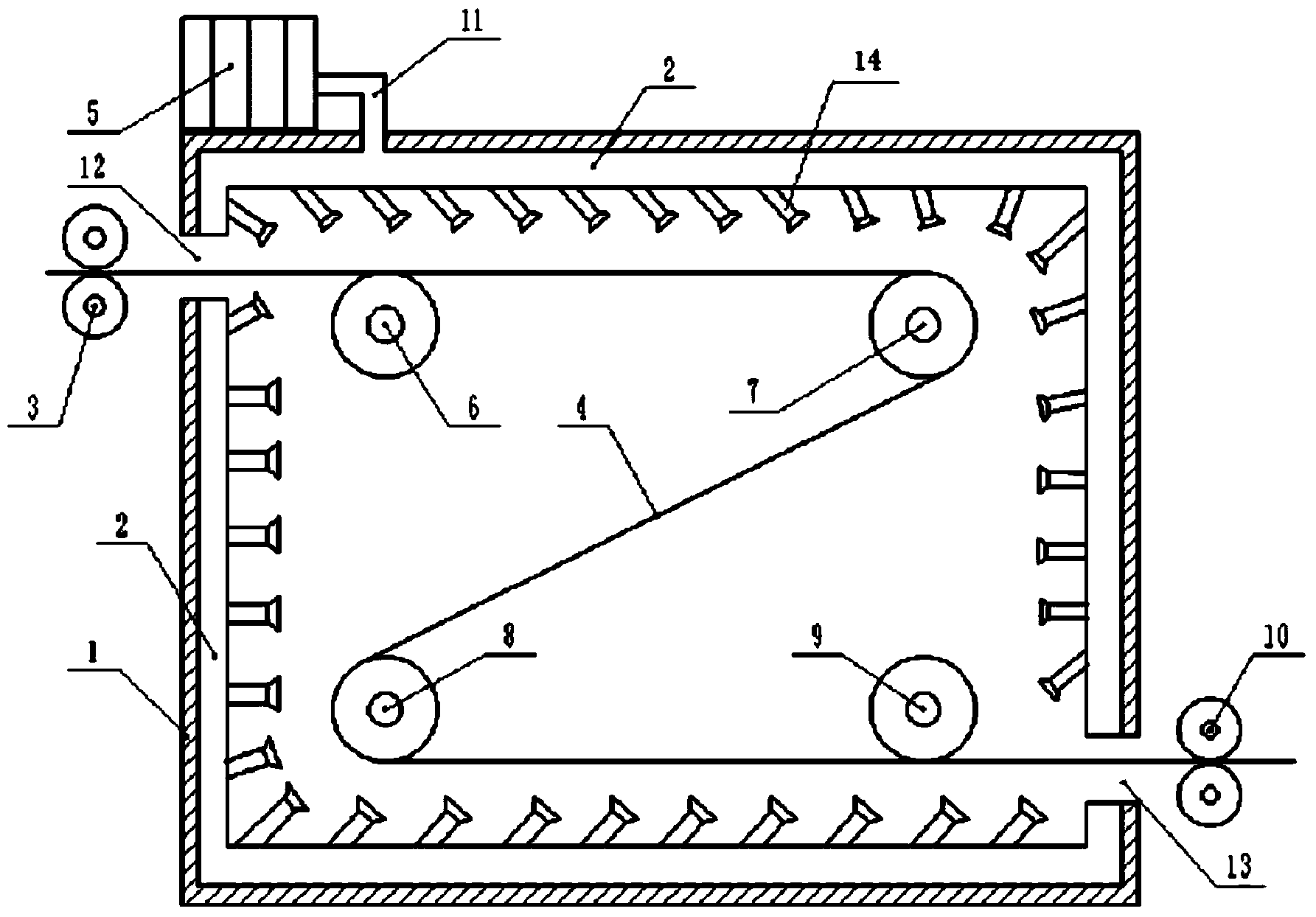

[0012] see figure 1 , a textile hot air drying device, comprising a box body 1, cloth 4 and a connecting pipe 11, the upper left side of the box body 1 is provided with a feed port 12, and the left side of the feed port 12 is provided with a first pressure roller 3. The lower part of the right side of the box body 1 is provided with a discharge port 13, the right side of the discharge port 13 is provided with a second pressure roller 10, and the inner wall of the box body 1 is provided with a drying body 2, which is thin Wall cavity structure, several hot air nozzles 14 are evenly spaced on the drying body 2, and the orientations of the hot air nozzles 14 are different. The upper end of body 1 is provided with hot air blower 5, and hot air blower 5 is connected to drying body 2 through connecting pipe 11; The right side is provided with the secon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap