Performance test system and test method for explosion suppression and explosion resistance mining device

A test system and anti-explosion technology, which is applied to measurement devices, testing of machinery/structural components, instruments, etc., can solve problems such as the inability to simulate the negative pressure environment of the extraction pipeline, the inability to arbitrarily set the methane concentration, and the inability to obtain test results. , to avoid replacement, save costs and improve versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

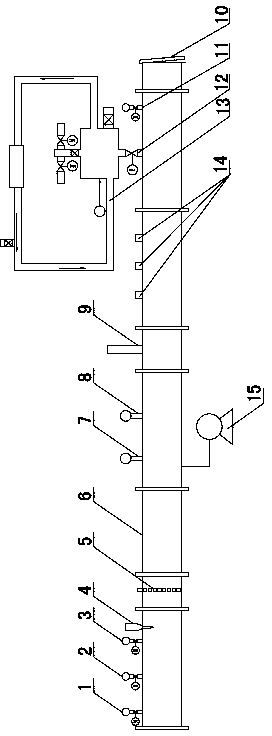

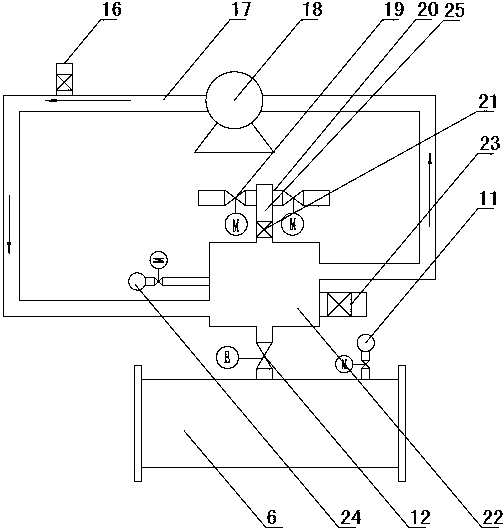

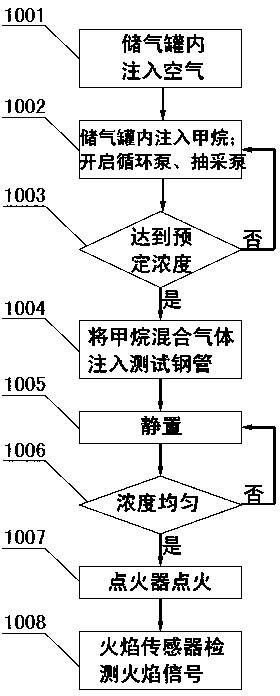

[0041] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~3 The present invention is described further:

[0042] Such as figure 1 As shown, the performance test system for mine anti-explosion and anti-explosion devices includes a test steel pipe 6 and a test gas supply unit 13 connected to one side of the test steel pipe 6 . The test steel pipe 6 is formed by connecting multiple steel pipes through flanges. The left end of the test steel pipe 6 is closed, and the right port is blocked by a baffle 10. The top of the baffle 10 is flexibly connected to the upper end of the test steel pipe 6, so that the baffle 10 can be opened. Closely, the right port of the test steel pipe 6 is blocked, and the test air supply unit 13 is fixed on the side close to the baffle plate 10 . In the existing performance testing system of explosion suppression and explosion arresting devices, the right port of the test steel pipe 6 is generall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com