Modular servo drive unit comprehensive test platform based on bus control

A technology of servo drive unit and test platform, applied in motor generator test, measurement device, measurement of electrical variables, etc., can solve the problems of unified control of different test units, obtaining batch test results, and high labor costs, reducing consumption and achieving accurate Test effect, the effect of reducing test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

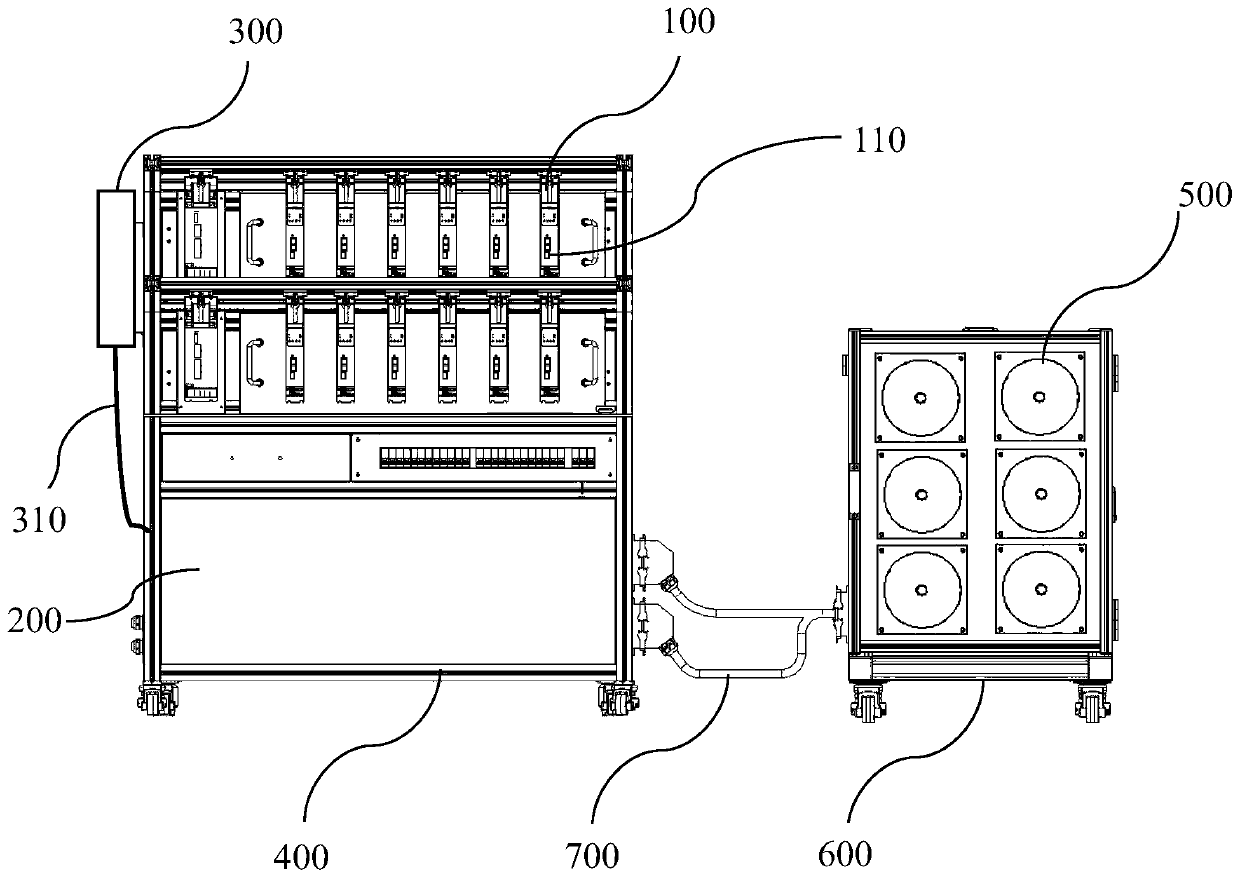

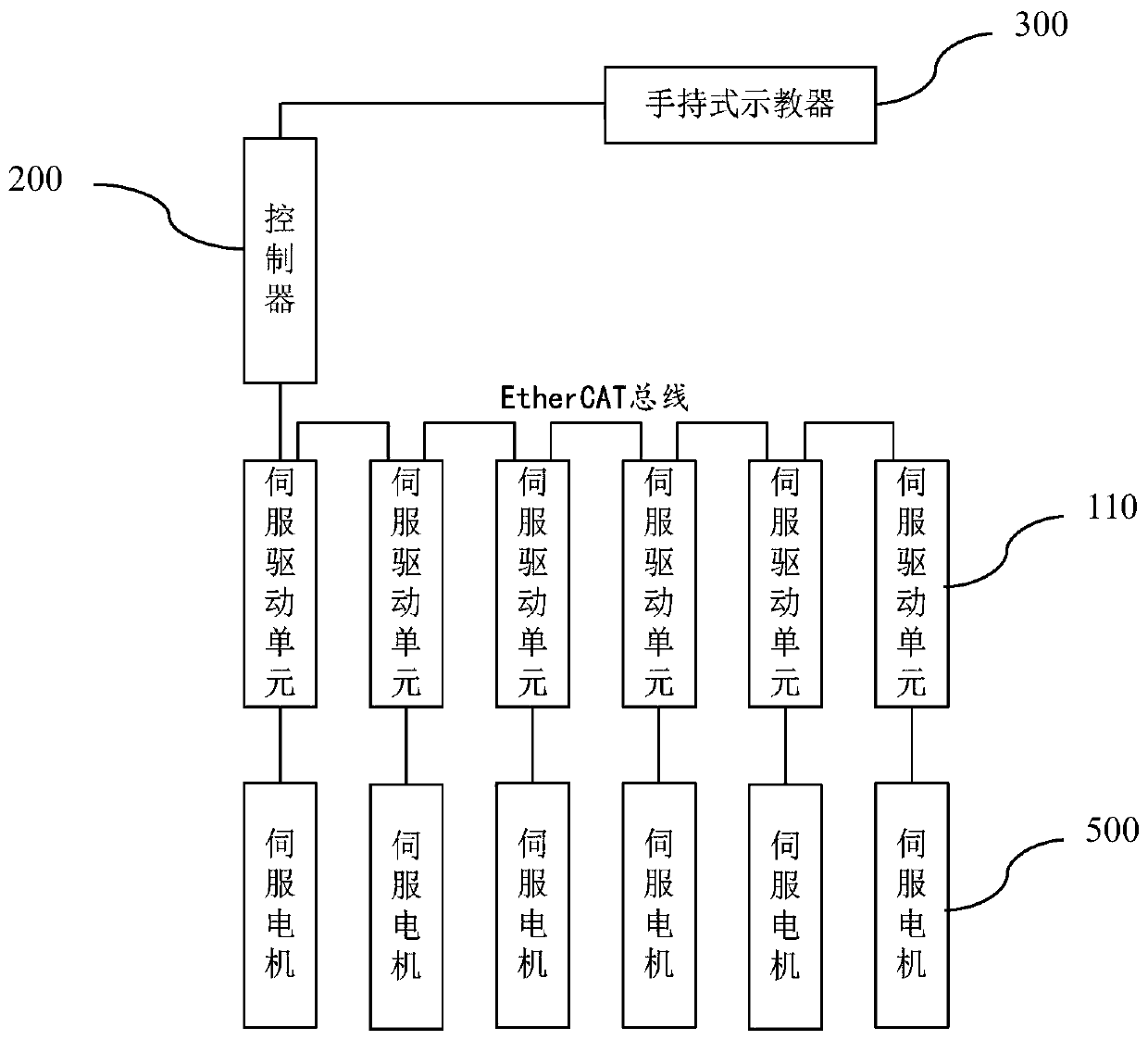

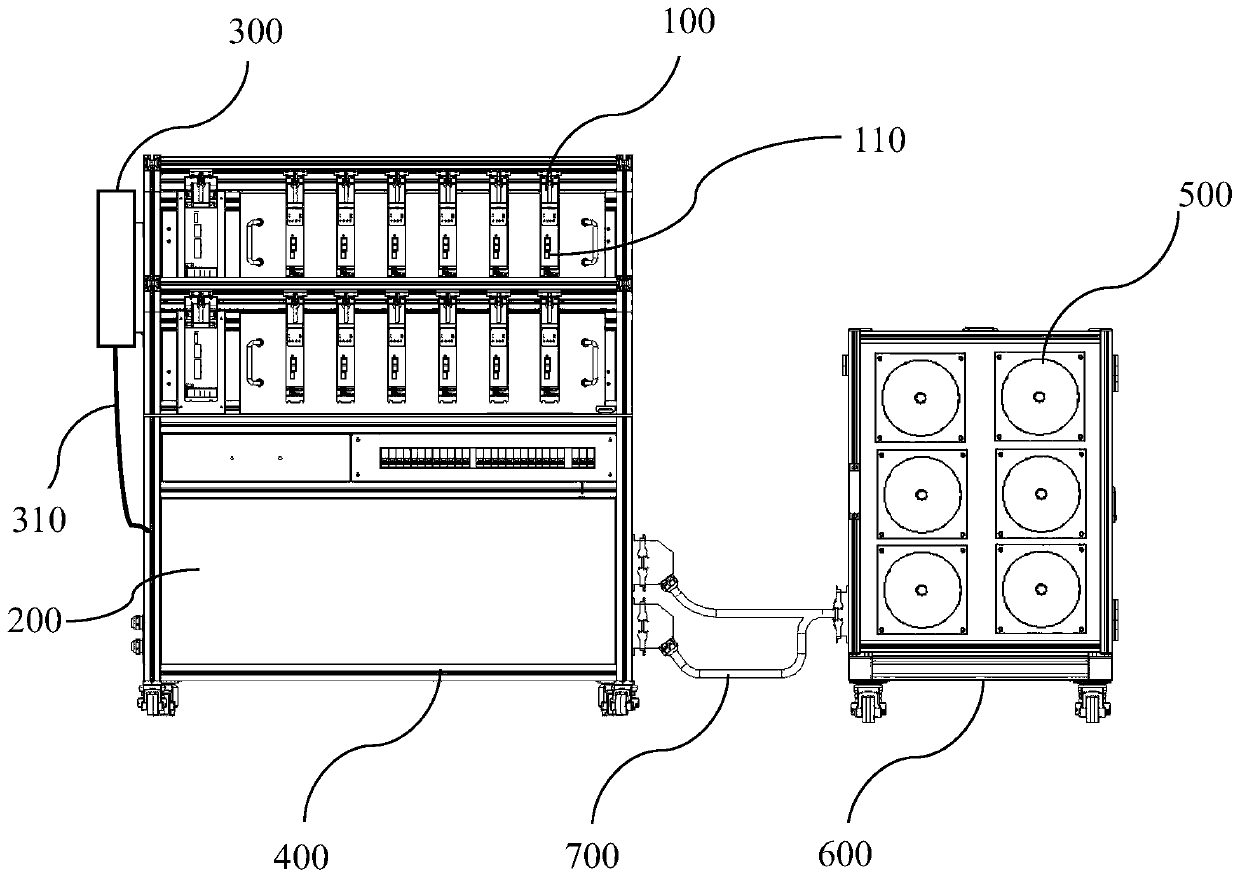

[0034] Such as figure 1 , 2 As shown, a modularized servo drive unit integrated test platform based on bus control includes:

[0035] A servo drive unit assembly 100, the servo drive unit assembly 100 includes a plurality of servo drive units 110;

[0036] The controller 200 is used to control the plurality of servo drive units 110;

[0037] Wherein, the plurality of servo drive units 110 are connected to the controller 200 through an Ethernet automatic control EtherCAT bus.

[0038] The EtherCAT bus is a field bus system based on Ethernet, and EtherCAT is a deterministic industrial Ethernet. EtherCAT bus control usually includes three control modes: serial link, timing search and independent request. The distribution of the right to use the bus in the serial link mode is realized through three control lines. The three control lines include: bus available, bus request and bus busy signal lines. Among them, all the functional components send a request to the bus controller via a comm...

Embodiment 2

[0043] Such as figure 1 , 2 As shown, on the basis of Embodiment 1, the test platform further includes: a handheld teach pendant 300, and the handheld teach pendant 300 is connected to the controller 200 through the TCP / IP protocol, The controller 200 inputs control instructions through the handheld teach pendant 300. Further, there are multiple groups of the servo drive unit assembly 100, and each group of the servo drive unit assembly 100 is equipped with a handheld teach pendant 300.

[0044] Further, the handheld teach pendant 300 and the controller 200 are electrically connected via a network cable 310 or wirelessly connected via a WiFi network.

[0045] The handheld teach pendant 300 is equivalent to an input device of the controller 200. By writing about the handheld teach pendant 300, the operator can perform test operations without standing in a fixed position in front of the console. With WiFi network wireless connection, the operator can even stay away from the console ...

Embodiment 3

[0047] Such as figure 1 , 2 As shown, on the basis of Embodiment 1 or 2, further the plurality of servo drive units 110 in the same group of the servo drive unit assembly 100 are connected in series and then connected to the controller 200 through the EtherCAT bus.

[0048] This embodiment means that each EtherCAT bus is connected in series with only the plurality of servo drive units 110 in one set of the servo drive unit assembly 100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com