Tester for rapidly testing heat-insulation property of fabric

A technology of thermal insulation performance and tester, which is applied in the direction of thermal development of materials, etc., to achieve the effects of reducing errors, accurate testing, and reducing temperature errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

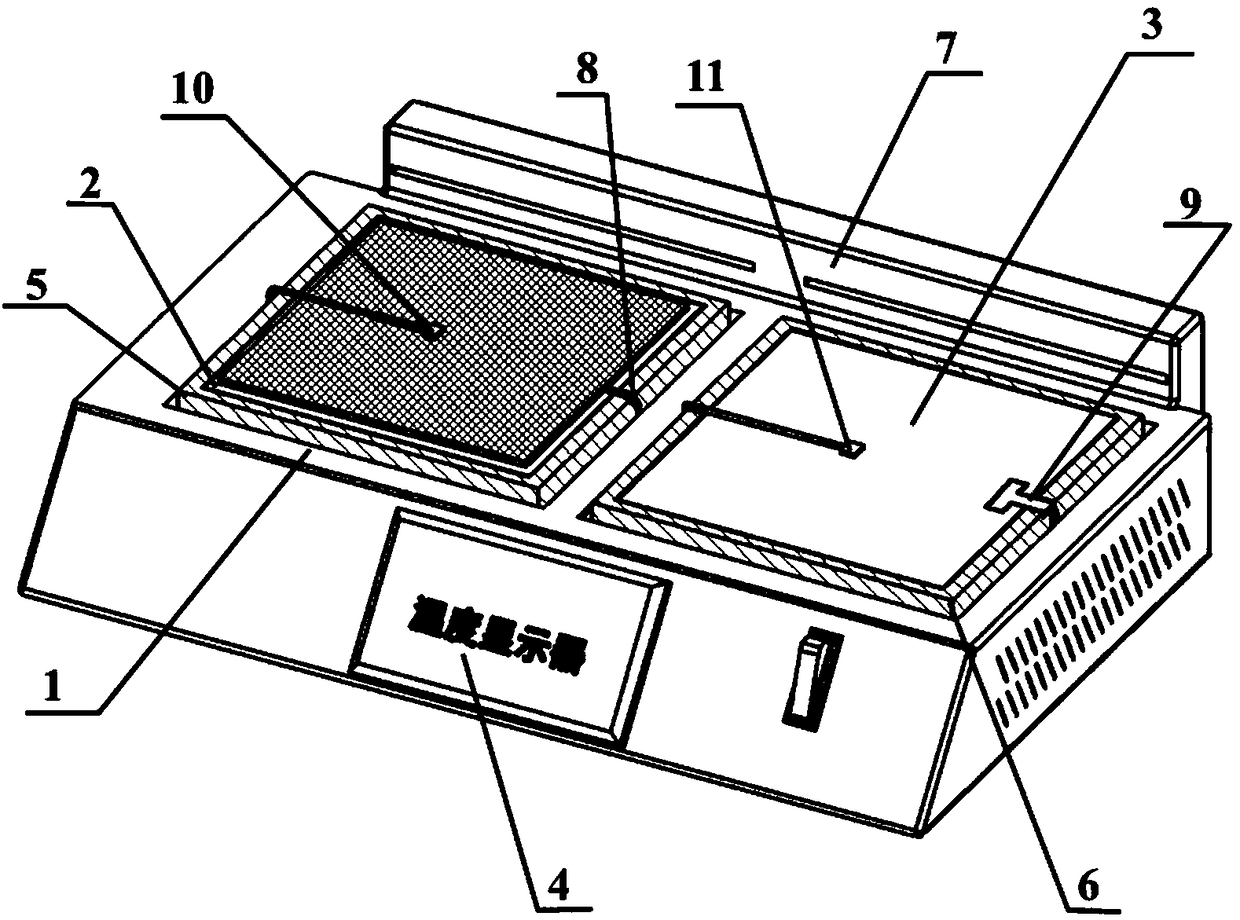

[0036] A tester for quickly testing the thermal insulation performance of fabrics. A test heating plate 2 and a reference heating plate 3 are respectively installed on the upper part of the instrument testing platform 1, and first heat insulation and heat preservation plates are respectively installed around the test heating plate 2 and the reference heating plate 3. 5. The second thermal insulation board 6 is equipped with an airflow generator 7 on one side of the test heating plate 2 and the reference heating plate 3. The temperature acquisition control module 4 collects the heating plate temperature sensor 8, the reference heating plate temperature sensor 9, the fabric The temperature of the temperature sensor 10 and the air temperature sensor 11, the temperature acquisition control module 4 controls the power on and off of the test heating plate 2 and the reference heating plate 3.

[0037] Center of test heating plate 2, reference heating plate 3, first insulation panel 5,...

Embodiment 2

[0040] Take a pure cotton fabric with an area of 20cm*20cm, place it on the test heating plate, under the fabric temperature sensor, turn on the test heating plate, and start heating with reference to the heating plate until it reaches 36 degrees Celsius, control the test heating plate through the temperature acquisition control module, and refer to the heating Turn on and off the power of the board to keep the temperature constant. The temperature of the test heating board and the reference heating board is the same as that of the surrounding heat insulation board. The temperature of the reference heating board is diffused through the air, and the temperature of the test heating board is diffused through the fabric, and no airflow occurs. The average power required for the test heating plate and the reference heating plate to maintain a constant temperature within 10 minutes is 2.08W and 2.36W respectively, and the heat preservation rate of cotton fabric is calculated by the ...

Embodiment 3

[0042] Take a pure cotton fabric with an area of 20cm*20cm, place it on the test heating plate, under the fabric temperature sensor, turn on the test heating plate, and start heating with reference to the heating plate until it reaches 36 degrees Celsius, control the test heating plate through the temperature acquisition control module, and refer to the heating Turn on and off the power of the board to keep the temperature constant. The temperature of the test heating board and the reference heating board is the same as that of the surrounding heat insulation board. The temperature of the reference heating board is diffused through the air, and the temperature of the test heating board is diffused through the fabric. Turn on the airflow generator , select the wind speed to be 2 meters per second, the average power required by the test heating plate and the reference heating plate to maintain a constant temperature within 10 minutes is 3.48W, 4.56W respectively, and the cotton ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com