Determination method for failure parameters of materials with complex defects

A technology for complex defects and material failure, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve problems such as no method, and achieve the effect of simple measurement, high measurement accuracy, and wide application of defect objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with a plexiglass plate contains circular hole defect example, the inventive method is described in further detail:

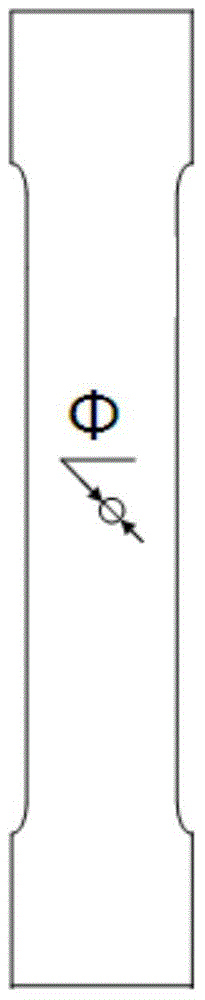

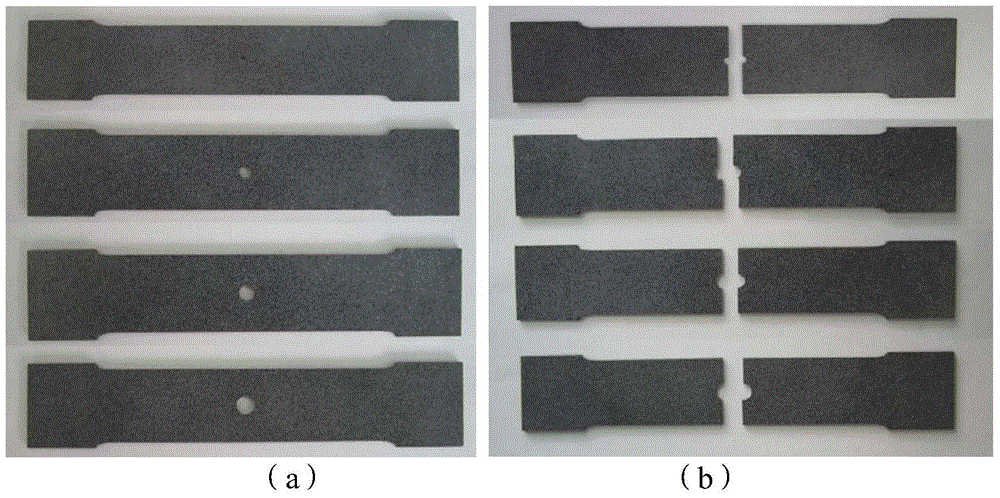

[0035] (1) The test piece in the example is as figure 1 As shown, a hole is punched with the geometric center of the specimen as the center. Among them, the thickness of the test piece is 2mm, and the hole diameters are 2mm, 4mm, 5mm, and 6mm respectively, and a total of 4 ( image 3 ). The elastic modulus of organic glass material is 3.0GPa, and the linear elastic Poisson's ratio is 0.35.

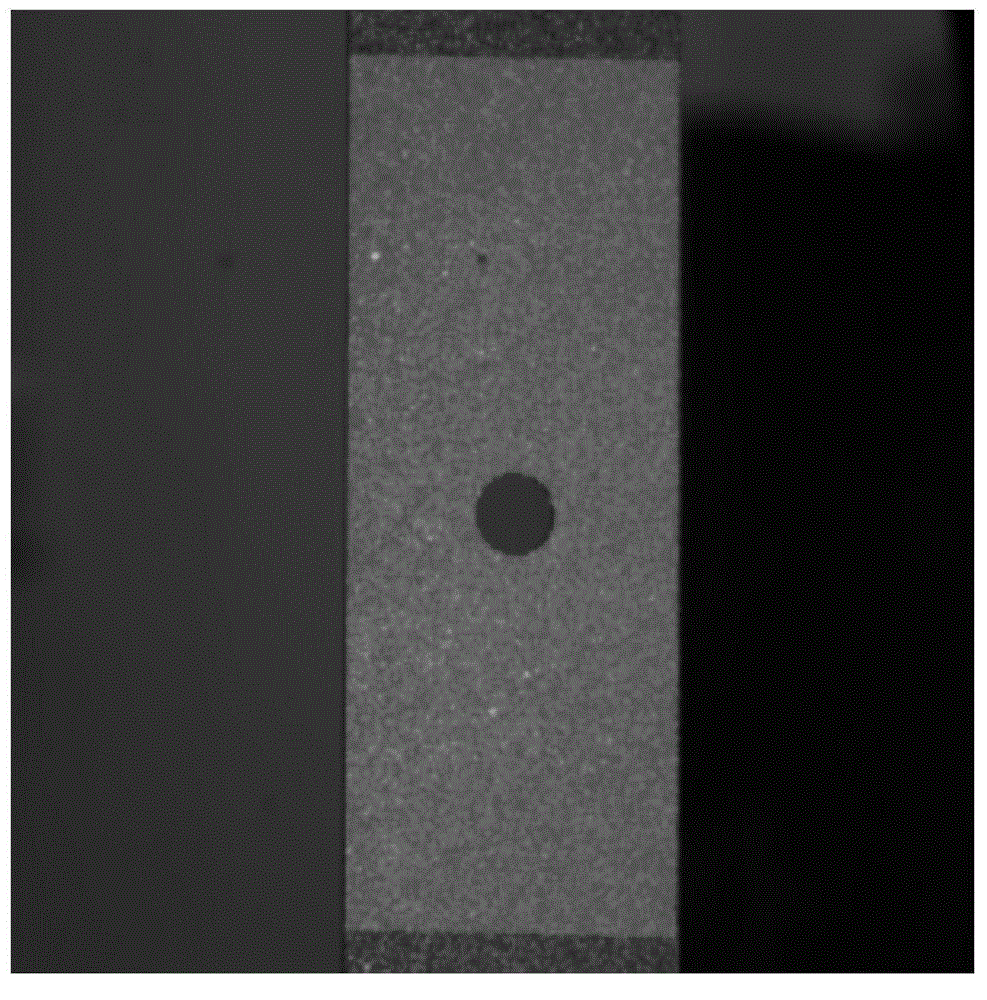

[0036] (2) The surface of the material specimen is polished, and then the surface of each specimen is sprayed with two types of anti-reflective paint with large color difference (such as black and white) to form a speckle state with high contrast, fine particles, and random distribution , which is convenient for the identification and calculation analysis of the lens, and the speckle pattern of the specimen is as follows figure 2 shown.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com