A fuse installation structure

An installation structure and fuse technology, applied in the field of electrical components, can solve the problems of accidental contact conduction, danger, easy to fall off, etc., and achieve the effects of enhanced reliability, accurate and reliable positioning, and reliable fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

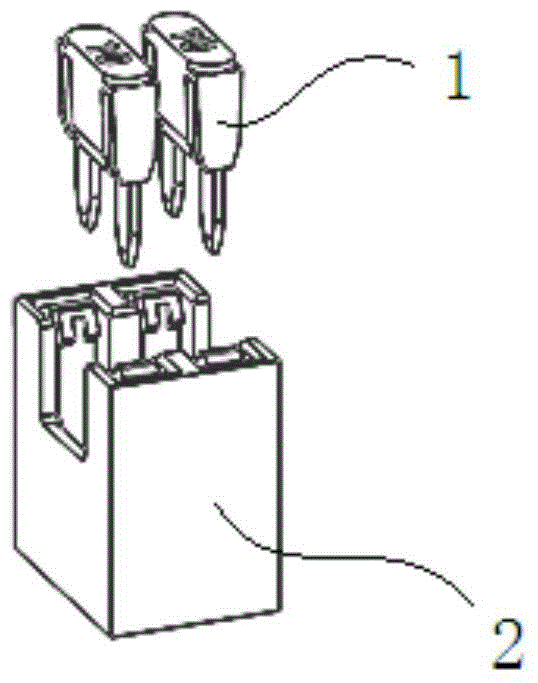

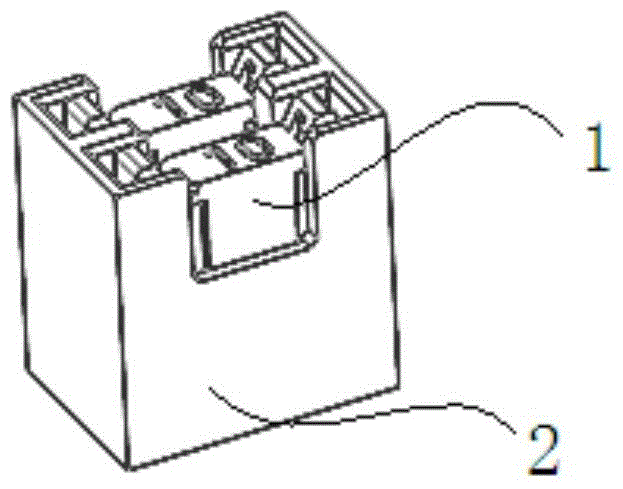

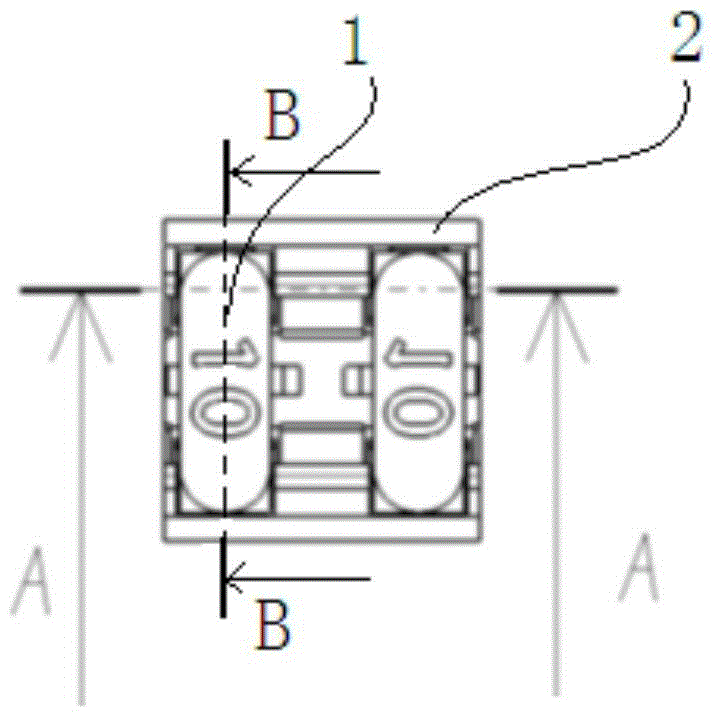

[0054] refer to Figure 6 , the fuse installation structure in this embodiment includes two parts, the fuse seat 200 and the electrical box body 300, and for clarity, the metal terminal 400 fixed in the electrical box body 300 is exploded as a single component. The fuse seat 200 is used to install the fuse 100 , and the fuse seat 200 is inserted into the electrical box body 300 to complete the installation of the fuse 100 .

[0055] refer to Figure 7 , in this embodiment, the fuse 100 is a 10A blade type fuse, the fuse 100 has two pins 110, and the length of the pins is h7. This fuse is commonly used in the automotive field. The blade fuse 100 is used as an example in the following descriptions, but those skilled in the art should understand that the fuse holder 200 can also be installed with various types and types of fuses such as glass tube type and ceramic tube type.

[0056] combine Figure 8 , Figure 9 with Figure 16 , Figure 25 , the fuse seat 200 has a fuse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com