Low-voltage power distribution cabinet safety protection method

A technology for safety protection and power distribution cabinets, applied to electrical components, emergency protection circuit devices, etc., can solve problems such as equipment burnout, failure to check the surface temperature of cables, and cable scrapping, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

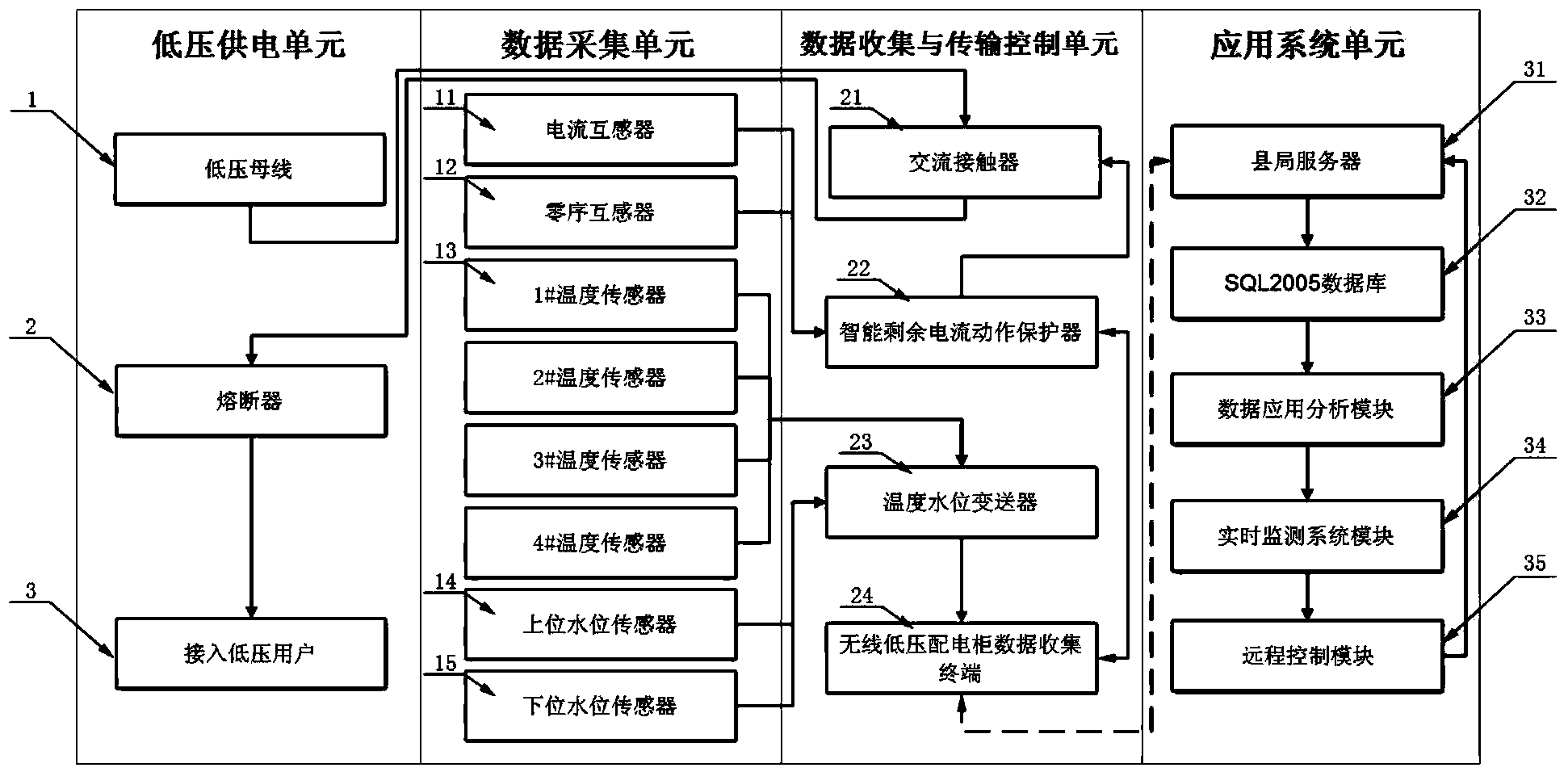

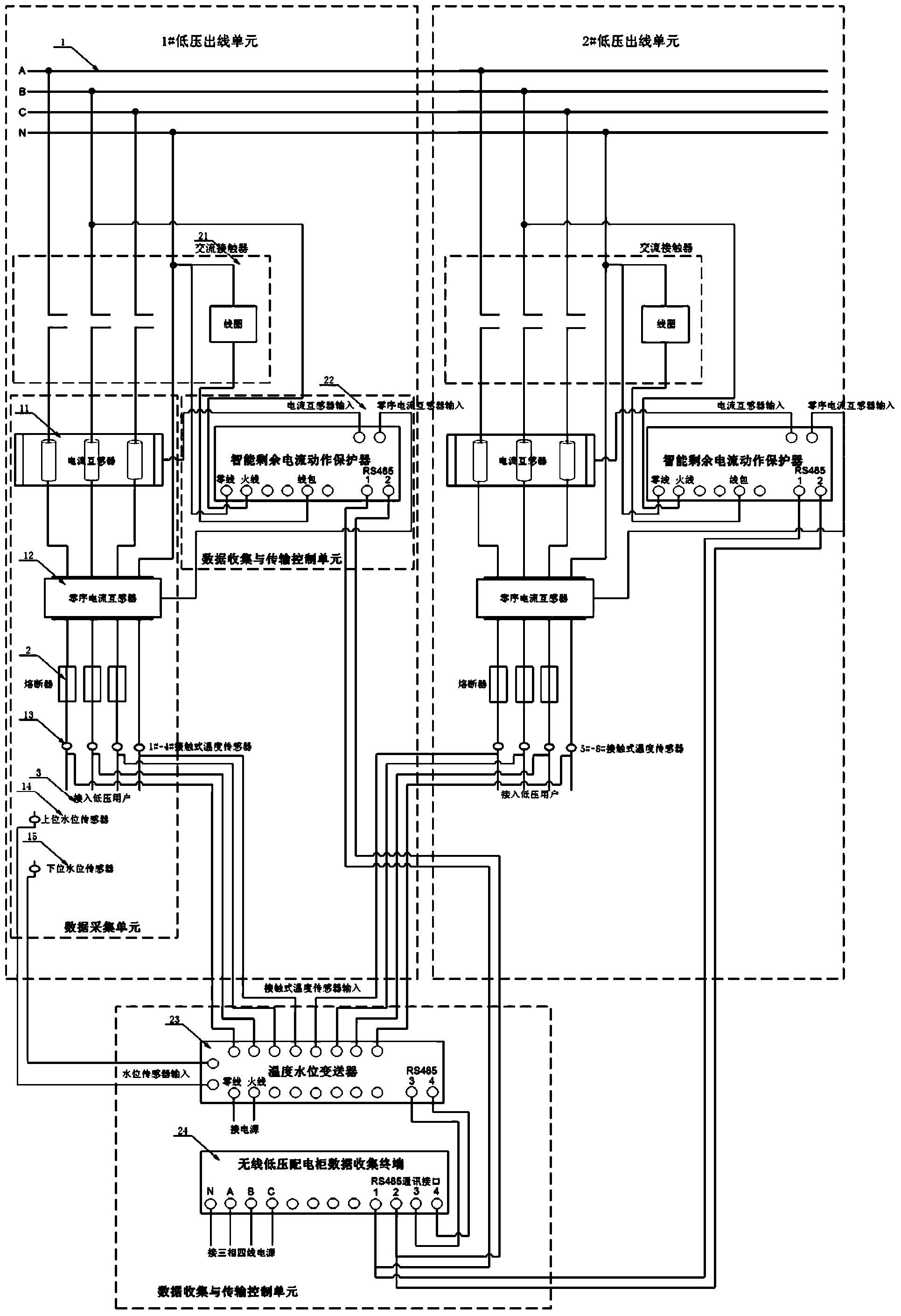

[0010] combine figure 1 and figure 2 The specific description is an embodiment of the improved structure of a low-voltage distribution cabinet safety protection device of the present invention, including a low-voltage bus 1, a fuse 2, a low-voltage user 3, a current transformer 11, a zero-sequence current transformer 12, and 1#-4# Contact temperature sensor 13, upper water level sensor 14, lower water level sensor 15, AC contactor 21, intelligent residual current action protector 22, temperature and water level transmitter 23, wireless low-voltage power distribution cabinet data collection terminal 24, county bureau server 31 , SQL2005 database 32, data application analysis module 33, real-time monitoring system module 34, remote control module 35.

[0011] Among them, the low-voltage busbar, AC contactor, fuse, and low-voltage users are connected to form a low-voltage power supply unit; current transformers, zero-sequence current transformers, 1#-4# contact temperature sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com