Method of feeding material to a horizontal shaft impact crusher, and a crushing device

一种冲击式破碎机、破碎装置的技术,应用在谷物处理等方向,能够解决很难挡板调节等问题,达到改善分布、磨损均匀、降低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

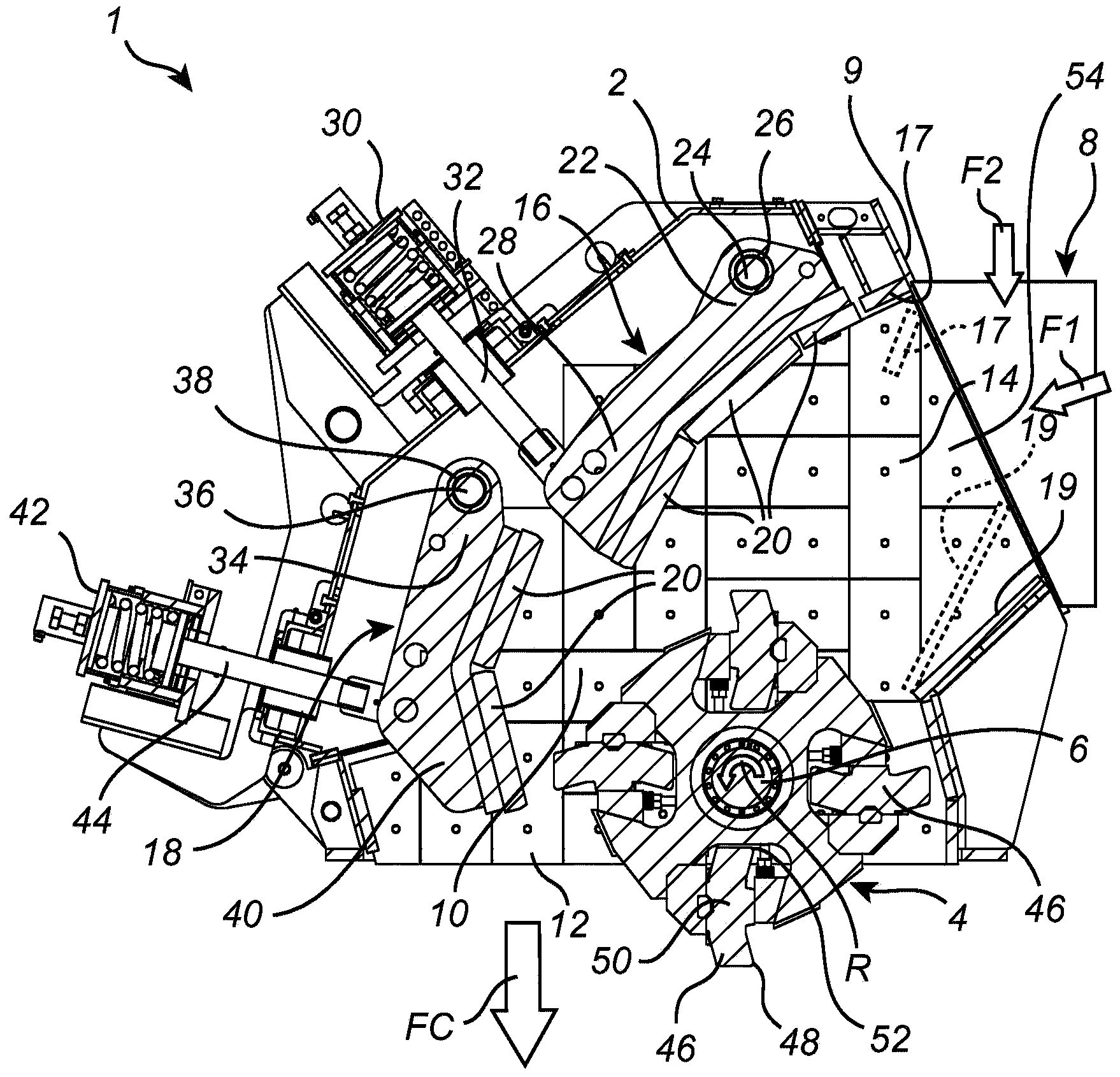

[0041] figure 1is a sectional view and schematically shows a crushing device including a horizontal shaft impact crusher 1 (HSI crusher). The horizontal shaft impact crusher 1 comprises a housing 2 in which an impeller 4 is arranged. A motor, not shown in order to preserve the clarity of the drawing, is operable to rotate the horizontal shaft 6 on which the impeller 4 is mounted. Instead of the impeller 4 being fixed to the shaft 6 , the impeller 4 is rotatable about the shaft 6 . In either case, the impeller 4 is operable to rotate about a horizontal axis coinciding with the center of the horizontal shaft 6 .

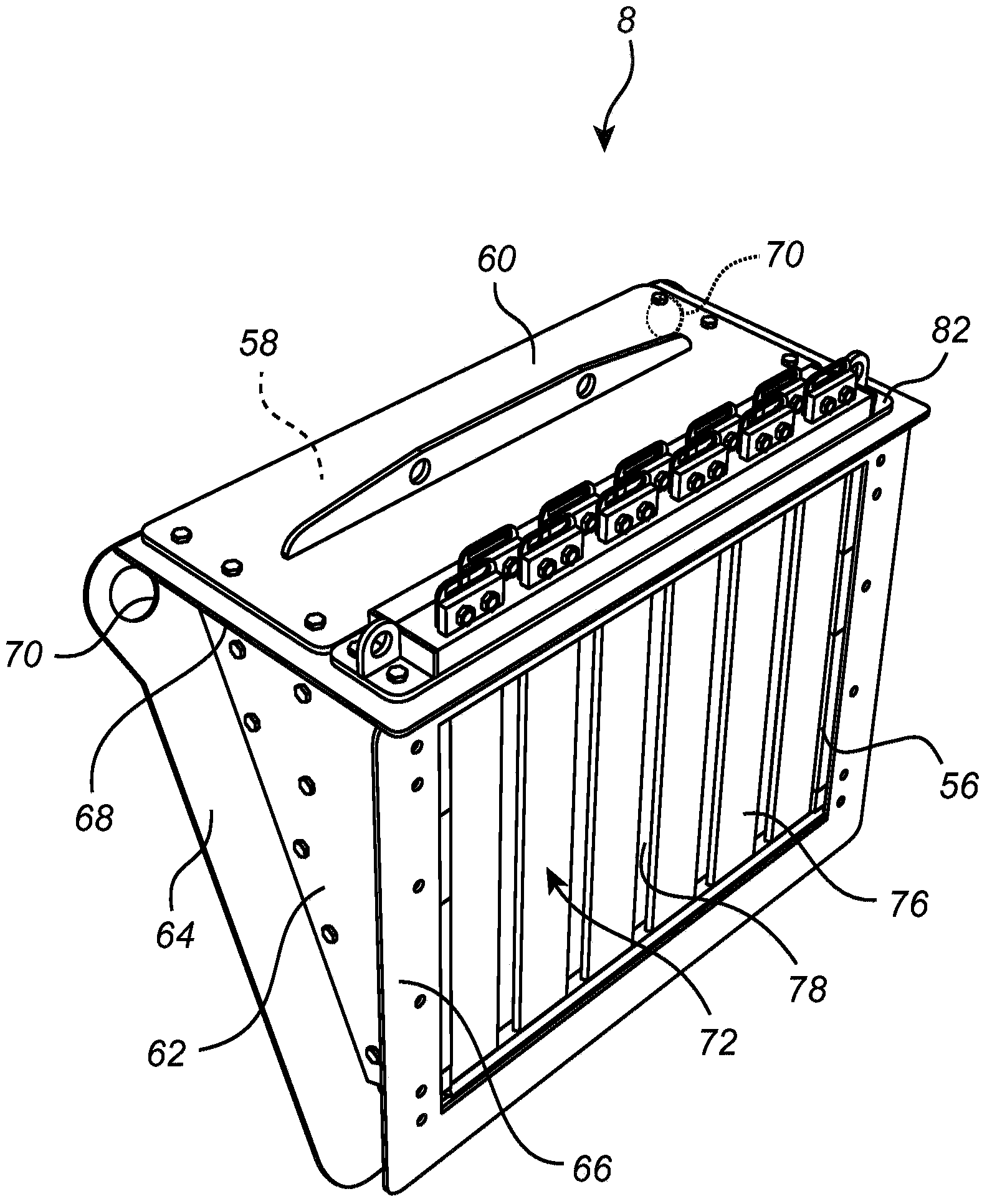

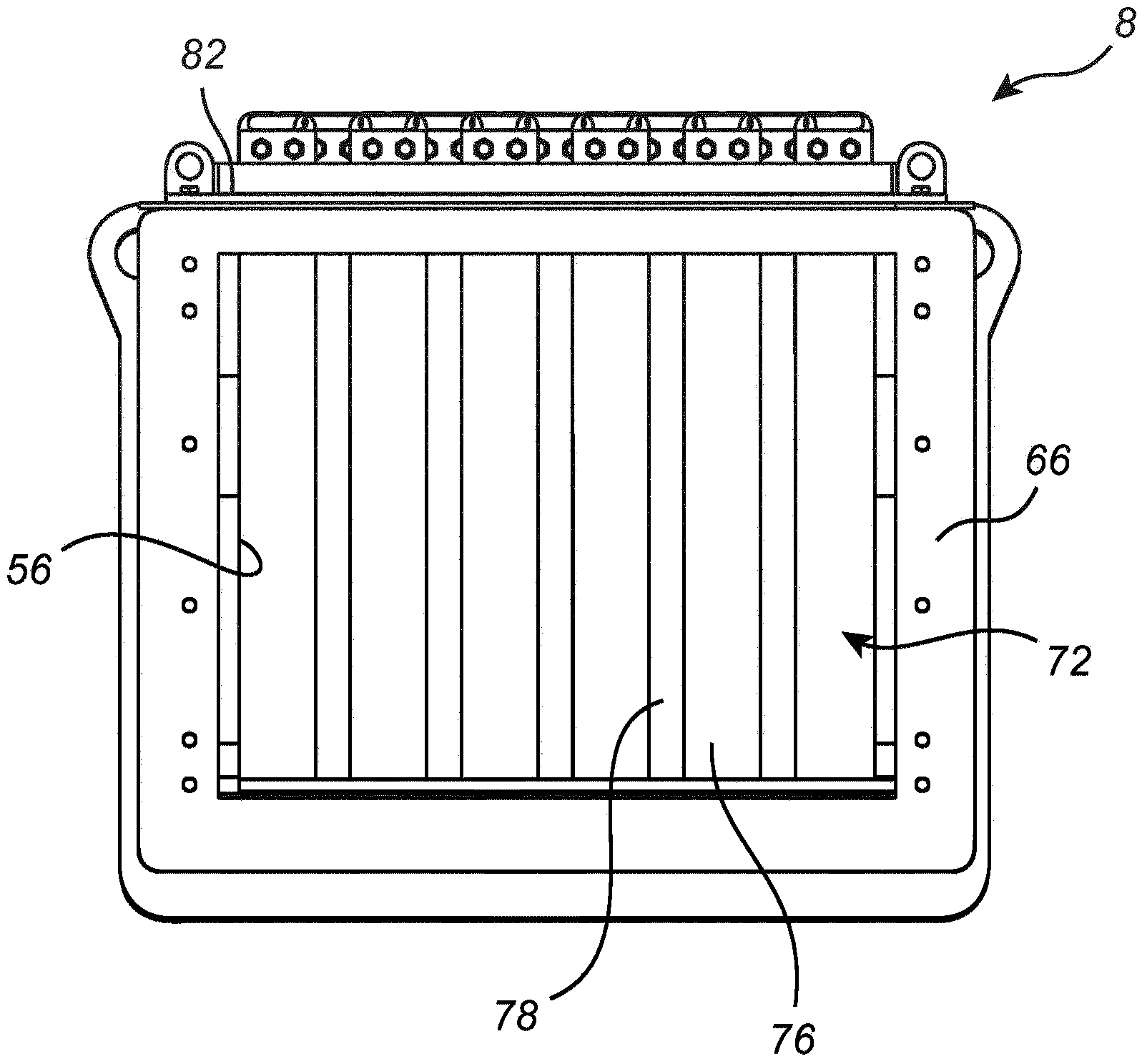

[0042] The material to be crushed is fed into a horizontal shaft impact crusher feed chute 8 mounted to the inlet flange 9 of the housing 2 and into a crushing chamber 10 arranged inside the housing 2 and at least partially surrounding the impeller 4 . The crushed material leaves the crushing chamber 10 via the crushed material outlet 12 .

[0043] The casing 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com