Mechanical seal

A technology of mechanical seal and sealing cover, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., and can solve the problems of weight increase and space limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

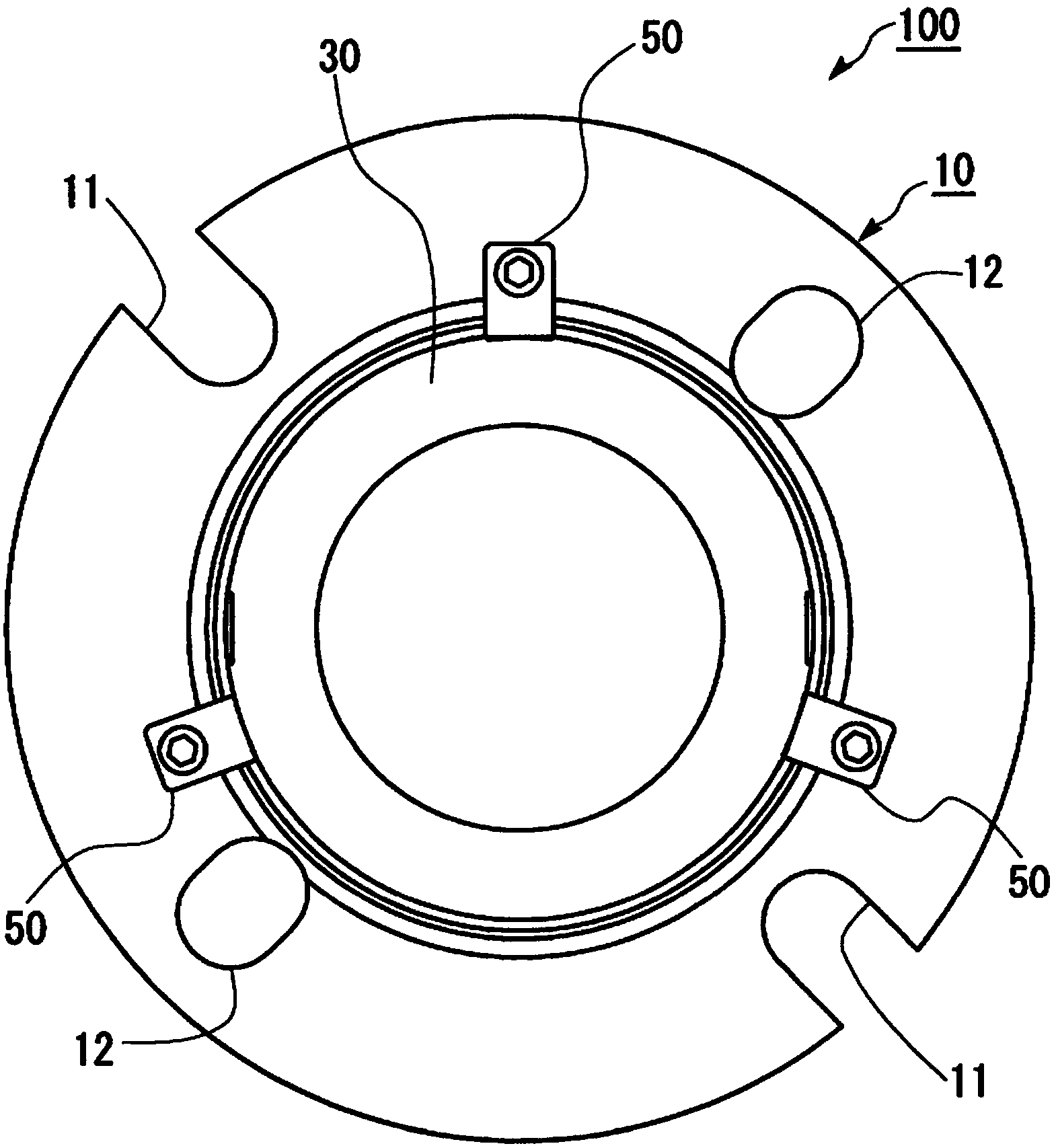

[0036] Refer below Figure 1 ~ Figure 2 A mechanical seal according to Embodiment 1 of the present invention will be described. In this embodiment, a mechanical seal commonly known as a cartridge mechanical seal is taken as an example, which simplifies the assembly work by providing a set plate temporarily fixing the seal cover and the collar of the rotating shaft.

[0037]

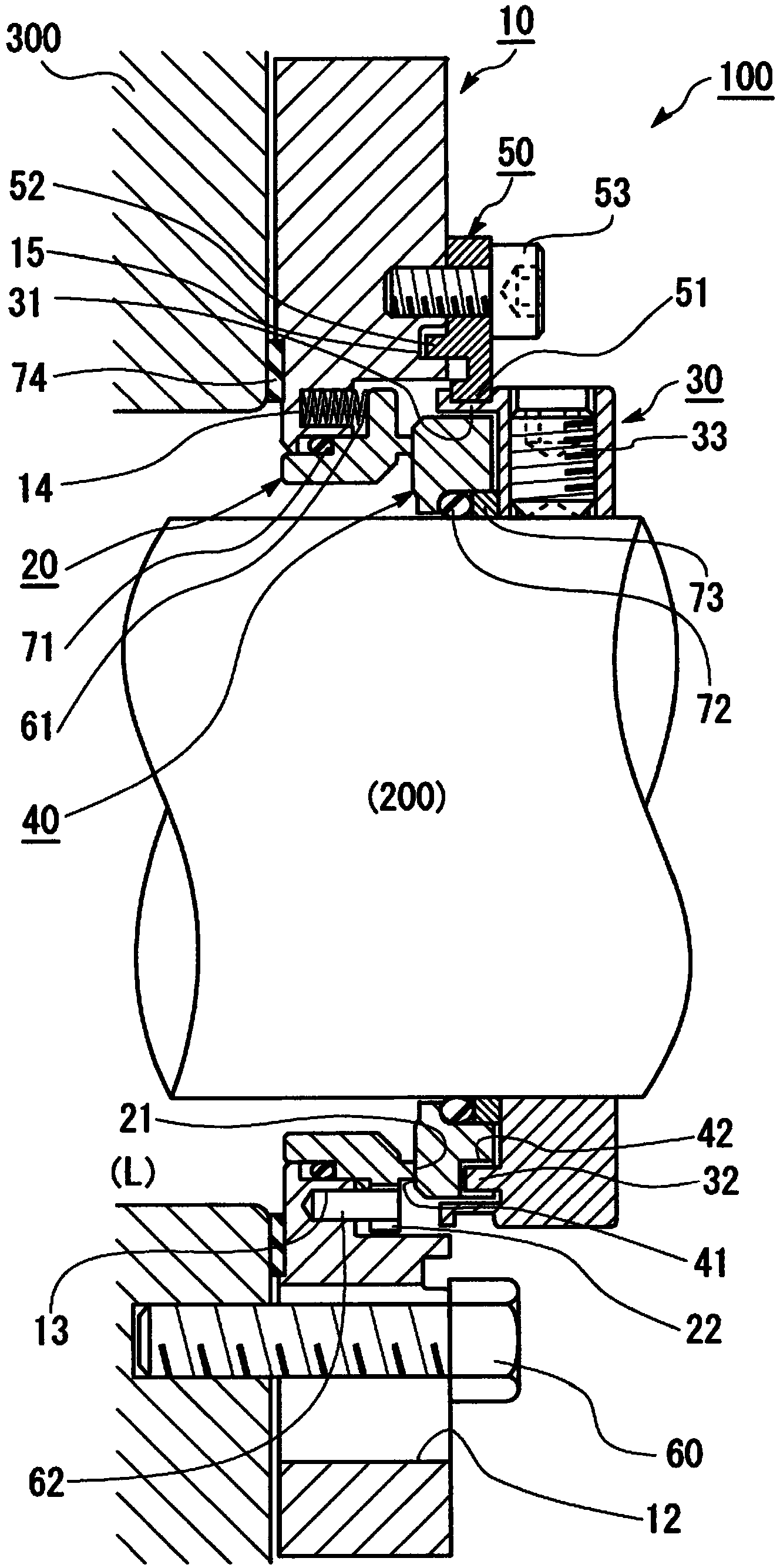

[0038] special reference figure 1 The overall structure of the mechanical seal in Embodiment 1 of the present invention will be described. figure 1 A schematic cross-sectional view showing a mechanical seal according to Embodiment 1 of the present invention in which a rotating shaft and a housing are assembled. figure 1 In , the cross-section of the mechanical seal is a cross-section including the central axis of each annular member constituting the mechanical seal (coinciding with the central axis of the rotating shaft). However, for the convenience of explanation, the phase of the cross-section i...

Embodiment 2

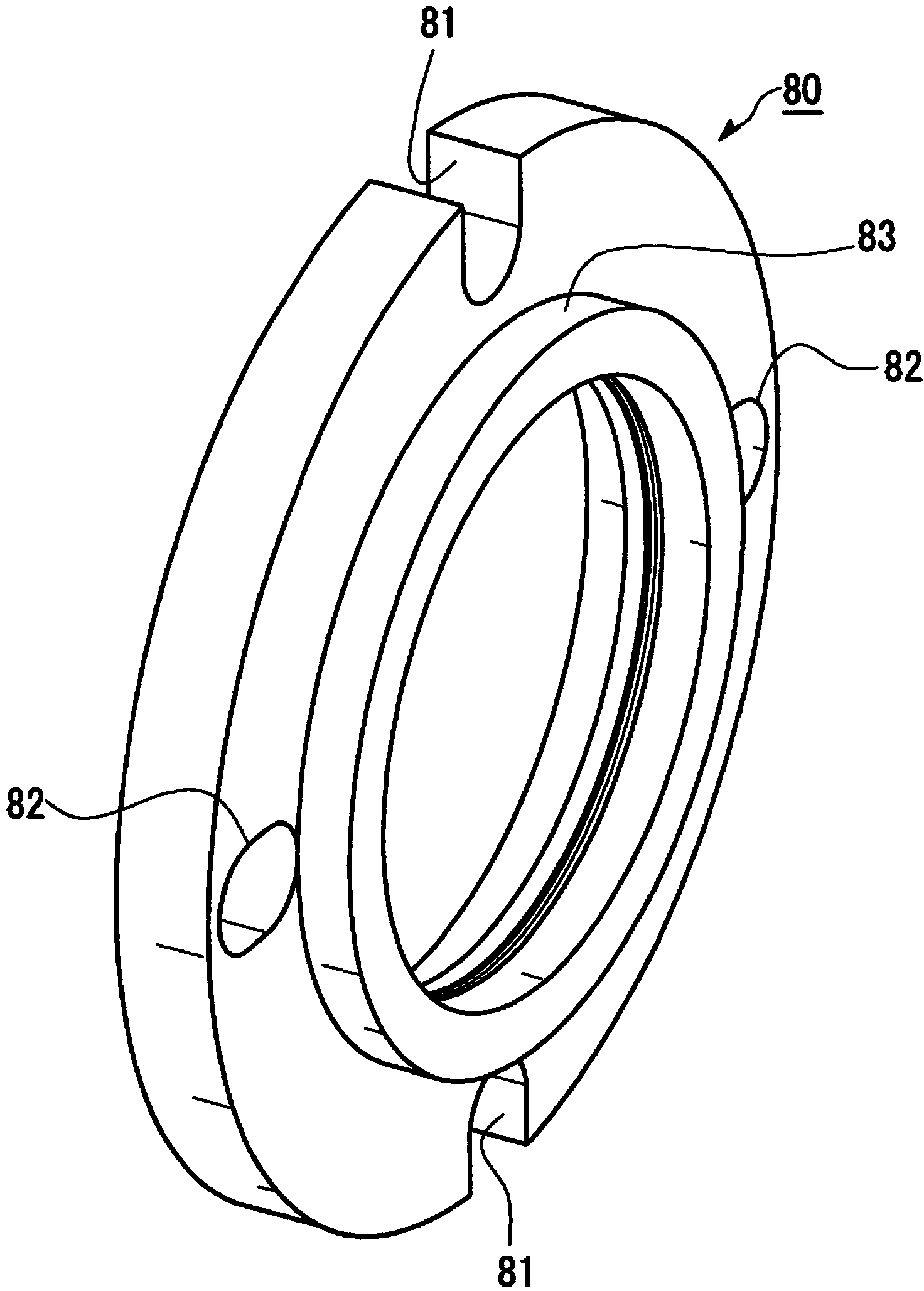

[0051] image 3 The sealing cover of the mechanical seal of Example 2 of the present invention is shown. image 3 It is a perspective view seen from the collar side when the mechanical seal of Example 2 is assembled. Such as image 3 As shown, the sealing cover 80 includes two U-shaped slots 81 and two elongated holes 82 for bolt fastening that are arranged alternately and at equal intervals in the circumferential direction of the shaft hole. The long hole 82 is elongated in the radial direction of the shaft hole, and is provided such that the innermost position of the hole through which the bolt shaft can pass is closer to the inner side than the innermost position of the U-shaped groove 81 through which the bolt shaft portion can pass. Since the effect achieved by the sealing cap 80 configured in this way is the same as that of the sealing cap 10 of Embodiment 1, description thereof will be omitted. The sealing cover 80 includes an annular protrusion 83 provided inside th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap