Multi-cell rotary end effector mechanism

A technology of end effectors and rotary actuators, which is applied in semiconductor/solid-state device manufacturing, manipulators, electrical components, etc., and can solve the problems of manufacturing output, battery efficiency sacrifice, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A workpiece handling system for solar cells is described here. However, embodiments may be used with other workpieces, such as semiconductor wafers, light emitting diodes (LEDs), and silicon-on-insulator (SOI) wafers, or other components. In addition to being used with ion implantation equipment, the workpiece handling system can also be used with other processing equipment, such as deposition, etching or other workpiece processing systems. Therefore, the present invention is not limited to the specific examples described below.

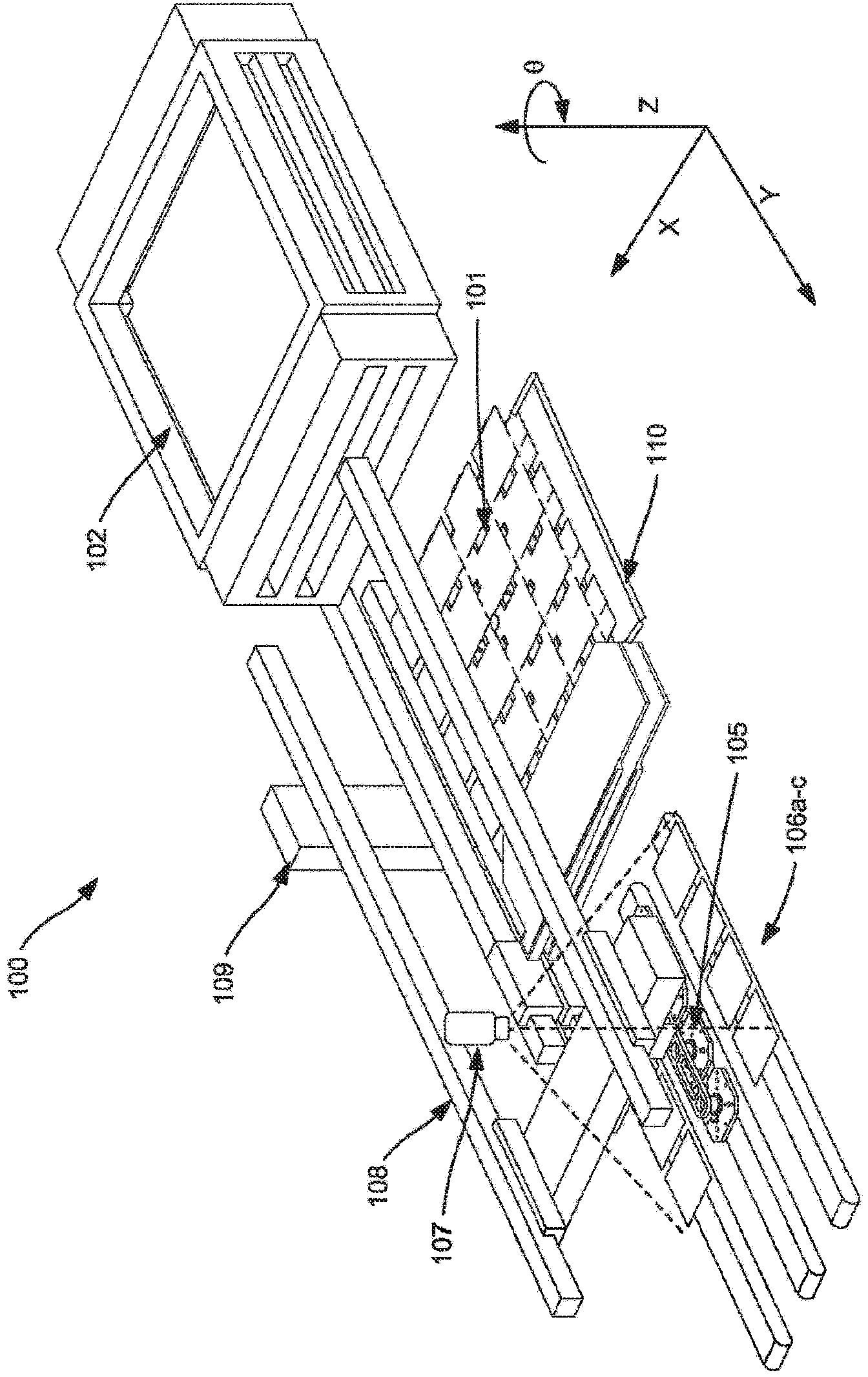

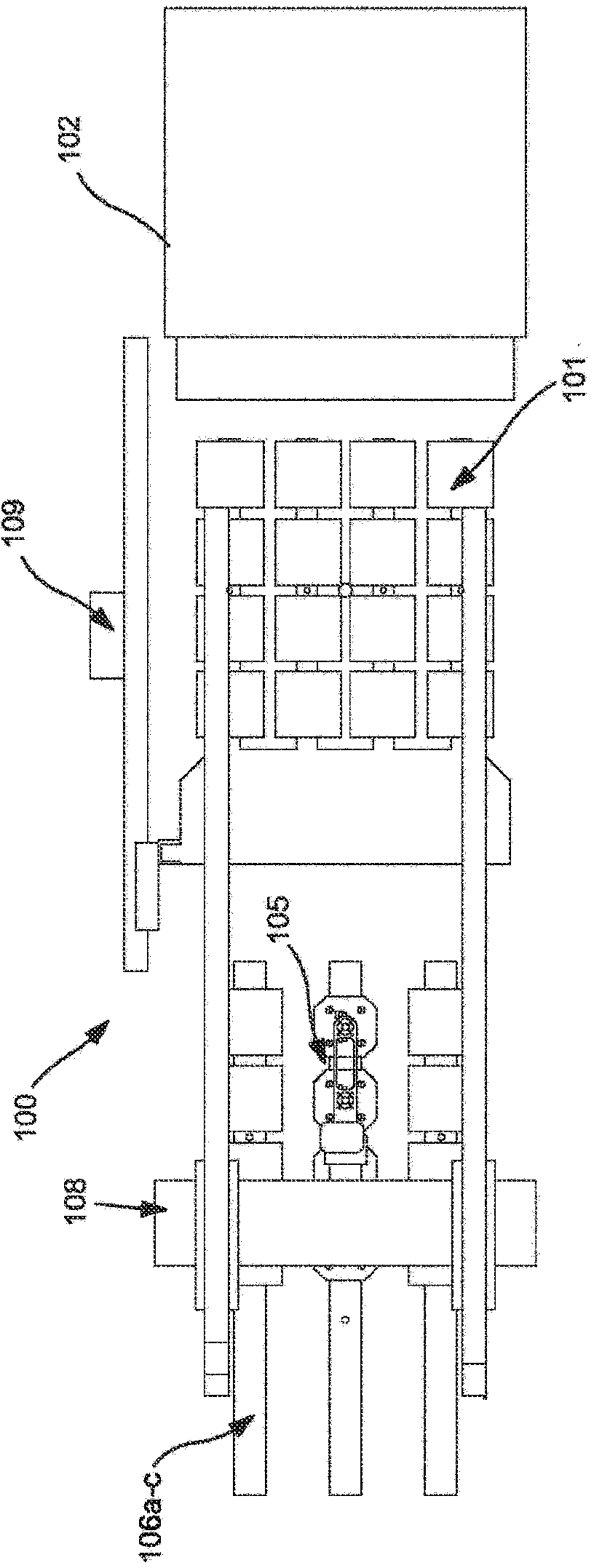

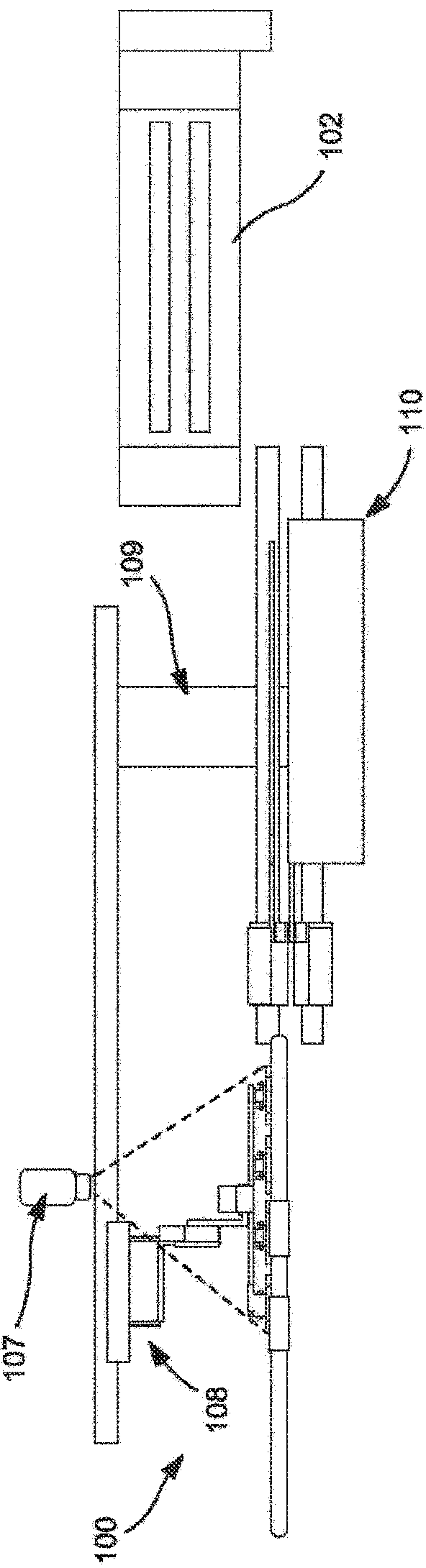

[0019] Figure 1 to Figure 3 The illustrated example workpiece handling system 100 can process over 2000 wafers per hour (wph) using a 4x4 workpiece matrix. Of course, other workpiece matrix designs can also be used, and the embodiment here is not limited to only 4x4 matrix. These figures represent a workpiece handling system, each individual element of which will be described in more detail below. figure 1 A perspective view showing the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com