Solid reagent clamping reactor

A technology for reactors and reagents, applied in the field of solid reagent clamping reactors, can solve problems such as hidden dangers in operation safety, easy introduction of impurities, troublesome operation, etc., and achieve the effects of preventing pollution, ensuring safe operation, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

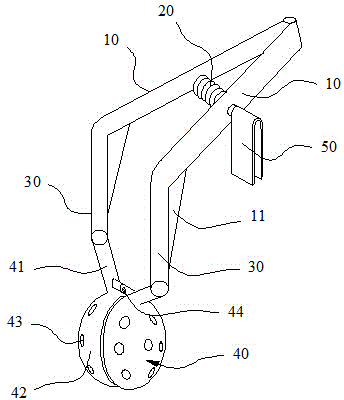

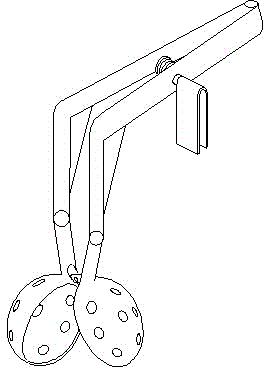

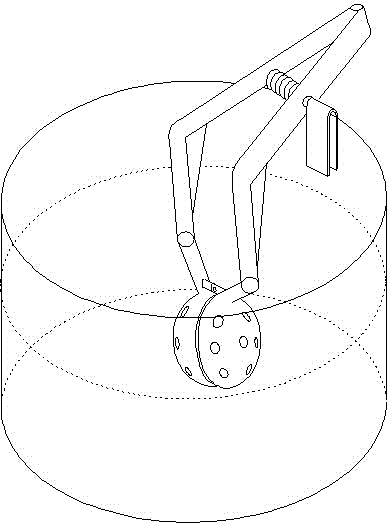

[0018] The invention provides a solid reagent clamping reactor, such as figure 1 As shown, the solid reagent clamping reactor has two long support arms 10 with the same length, one end of the two support arms 10 is rotatably connected together, and the middle parts of the two support arms 10 are abutted with compression Spring 20, the ends of the other ends of the two support arms 10 are respectively fixedly connected with a vertical extension arm 30, wherein the middle part of one support arm is hinged with an elastic clamp 50 on the side of the other support arm side; the elastic clamp 50 is An integrally formed U-shaped stainless steel sheet, and its U-shaped bending part is hinged on the side of the support arm; two vertical extension arms 30 are respectively vertically connected to the same side of the two support arms and have the same length, and the two vertical extension arms 30 A clamping spoon 40 made of transparent potassium glass material is rotatably connected to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap