A special mold for manufacturing grinding wheel

A grinding wheel and mold technology, which is applied in the field of special molds for manufacturing grinding wheels, can solve problems affecting the quality of grinding wheels and reduce the service life of molds, and achieve the effects of reducing production costs, prolonging service life, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

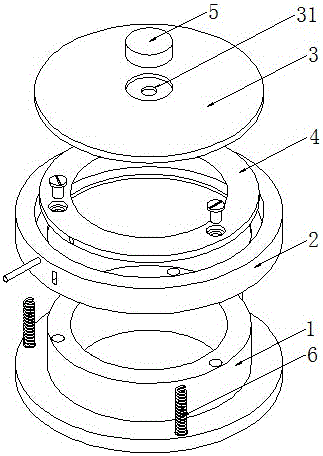

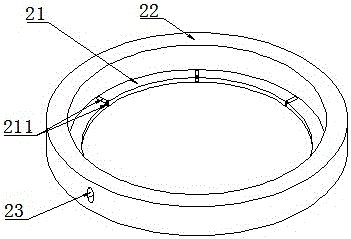

[0059] A kind of special mold for manufacturing grinding wheel of the present embodiment, such as figure 1 , figure 2 , image 3 As shown, it is mainly realized through the following technical solutions: a special mold for manufacturing grinding wheels, including a bottom mold 1, an outer upper mold 2, an inner upper mold 3, an inner middle mold 4, a core mold 5 and an elastic connector 6, the core The mold 5 is set inside the core hole 31 set in the center of the top surface of the inner upper mold 3, and the inner upper mold 3, the inner middle mold 4 and the bottom mold 1 are arranged coaxially from top to bottom and are all set inside the outer upper mold 2, The outer upper mold 2 is connected to the bottom mold 1 through an elastic connector 6; the bottom mold 1 includes a fixedly connected support cylinder 11 and a lower mounting platform 12, the center of the support cylinder 11 is provided with a first demoulding channel 13, and the inner middle mold 4 It is fixed o...

Embodiment 2

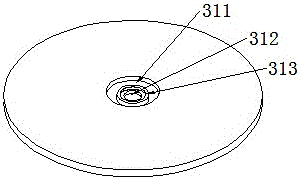

[0067] This embodiment is further optimized on the basis of the above embodiments, such as image 3 As shown, further, the core hole 31 is a through hole, including an upper through hole 311 and a lower through hole 312 arranged coaxially; the aperture of the upper through hole 311 is equal to the aperture of the core mold 5 and is larger than the lower through hole 312 The bottom surface of the upper through hole 311 is provided with a buffer pad 313, and the bottom surface of the mandrel 5 is close to the top surface of the buffer pad 313. Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

Embodiment 3

[0069] This embodiment is further optimized on the basis of the above embodiments, such as Figure 4 As shown, further, the core hole 31 is an equal-diameter through hole and the aperture of the core hole 31 is equal to the outer diameter of the core mold 5; a connecting plate 46 is arranged in the middle of the second demoulding channel 43, and the core mold 5 is fixed In the center of the connection plate 46 . Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com