Patents

Literature

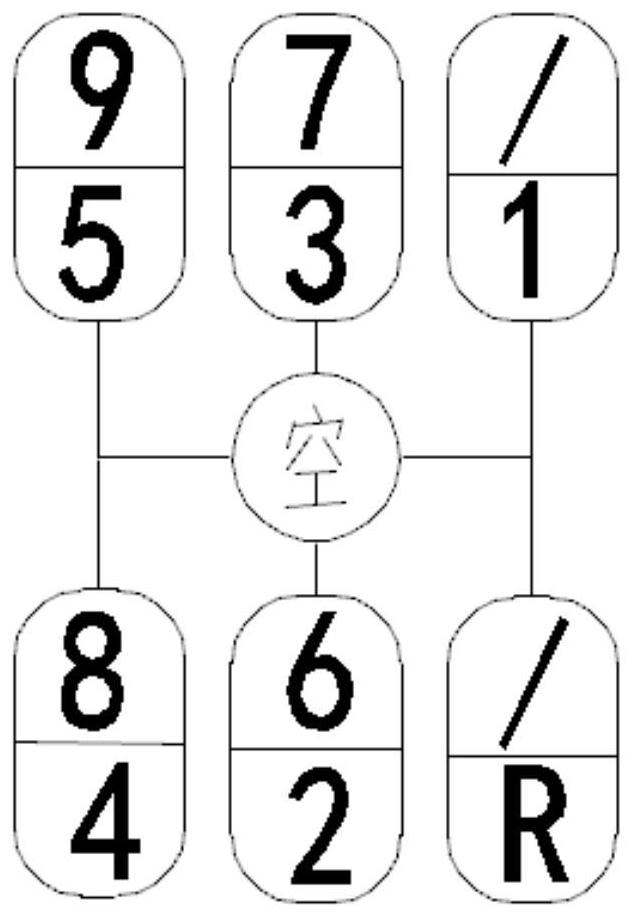

37results about How to "Short operating stroke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

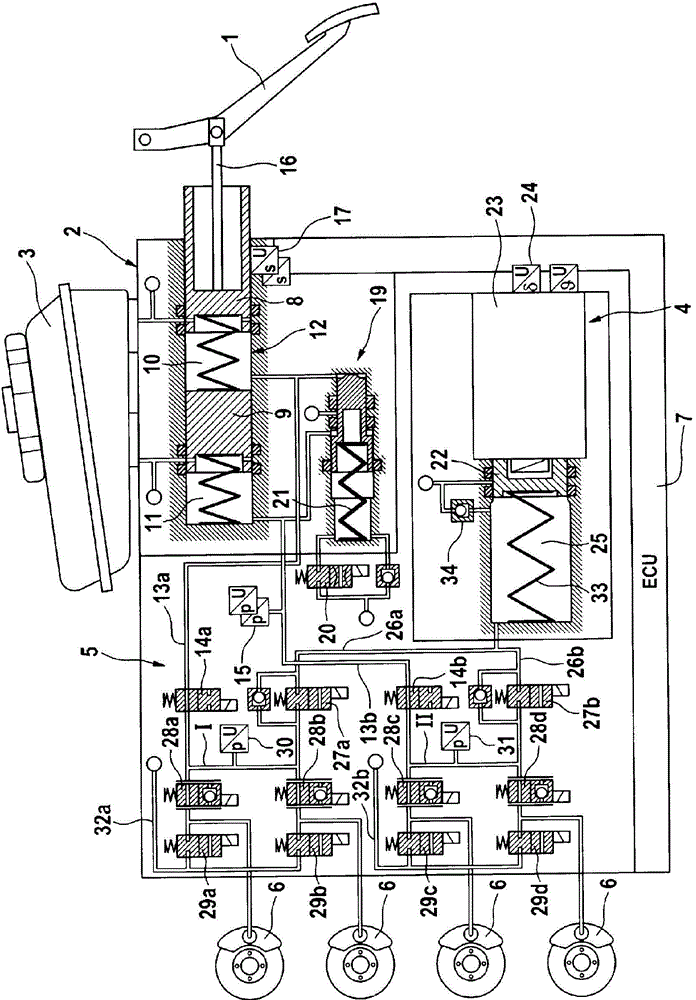

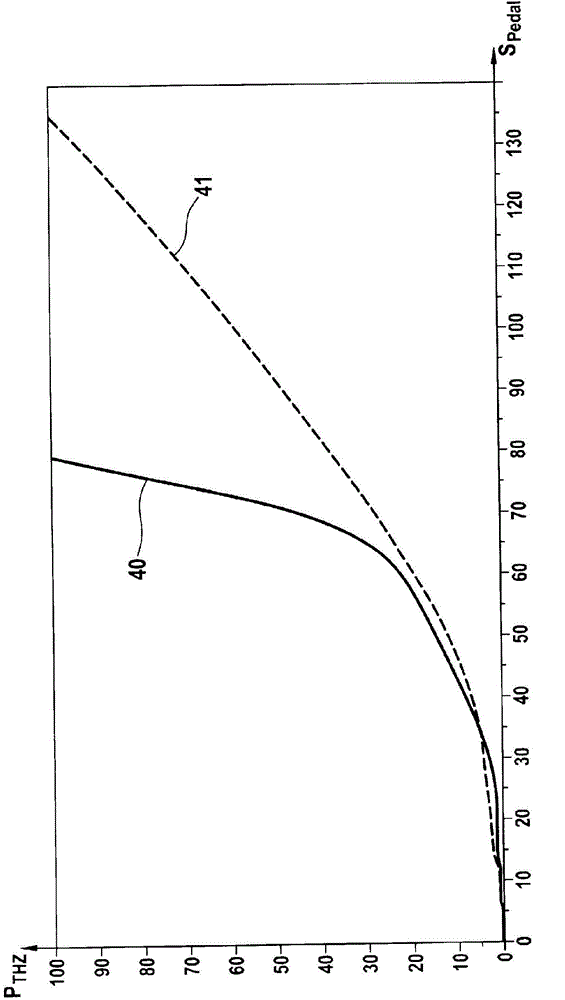

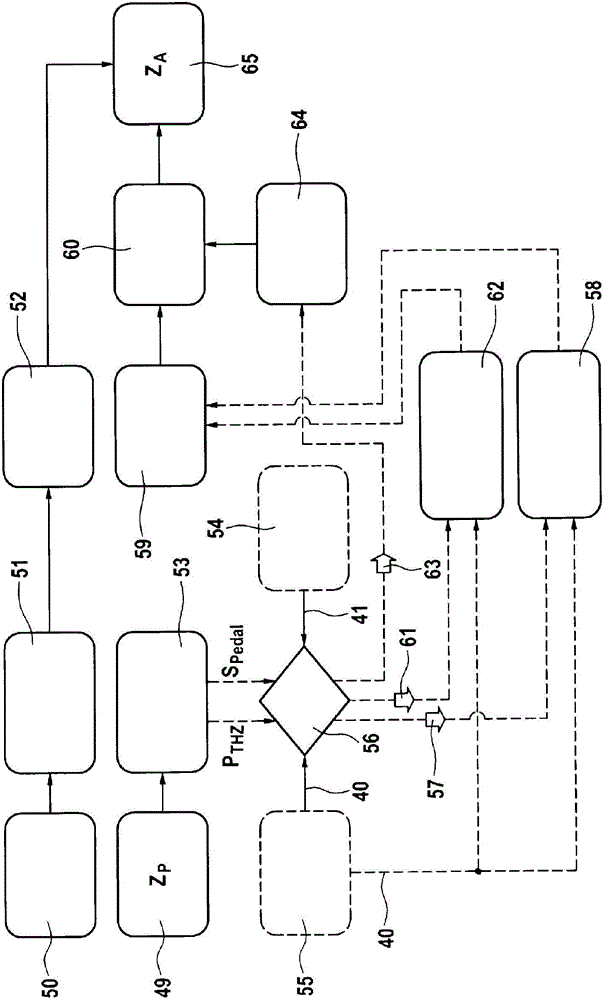

Method for operating a brake system for motor vehicles, and brake system

ActiveCN104105626AShort operating strokeCompensation pressure medium volumeBrake control systemsFluid braking transmissionAutomotive engineeringElectricity

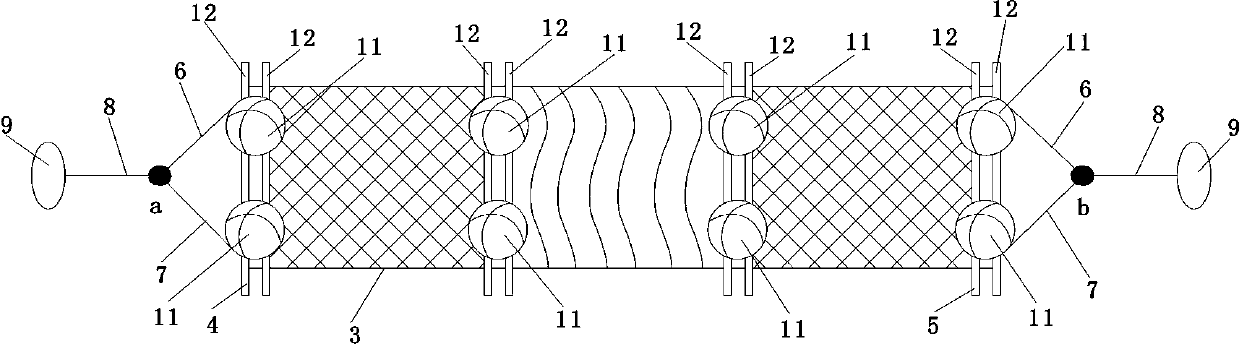

The invention relates to a method for operating a brake system for motor vehicles, comprising a master brake cylinder (12) that can be acuated by means of a brake pedal (1) and is separably (14a, 14b) connected to at least one hydraulically acutuatable wheel brake (6) by means of at least one brake circuit (I, II), a hydraulically operable pedal travel simulator (19) that is or can be connected to the master brake cylinder (12), an electrically controllable pressure provision apparatus (4) that is separably (27a, 27b) connected to the brake circuit (I, II), and an electronic open-loop and closed-loop control unit (7), wherein when the brake pedal (1) is actuated, a pressure (Ptarget) of the pressure provision apparatus (4) is applied to the brake circuit (I, II) in a first operating mode (ZA) and the pressure (PTHZ) of the master brake cylinder (12) is applied to the brake circuit (I, II) in a second operating mode (ZP), and wherein in the event of a transition from the second operating mode (ZP) to the first operating mode (ZA) while the brake pedal (1) is actuated, the actuation travel (SPedal) of the brake pedal (1) is adjusted by means of electronic open-loop or closed-loop control. The invention further relates to a brake system.

Owner:CONTINENTAL TEVES AG & CO OHG

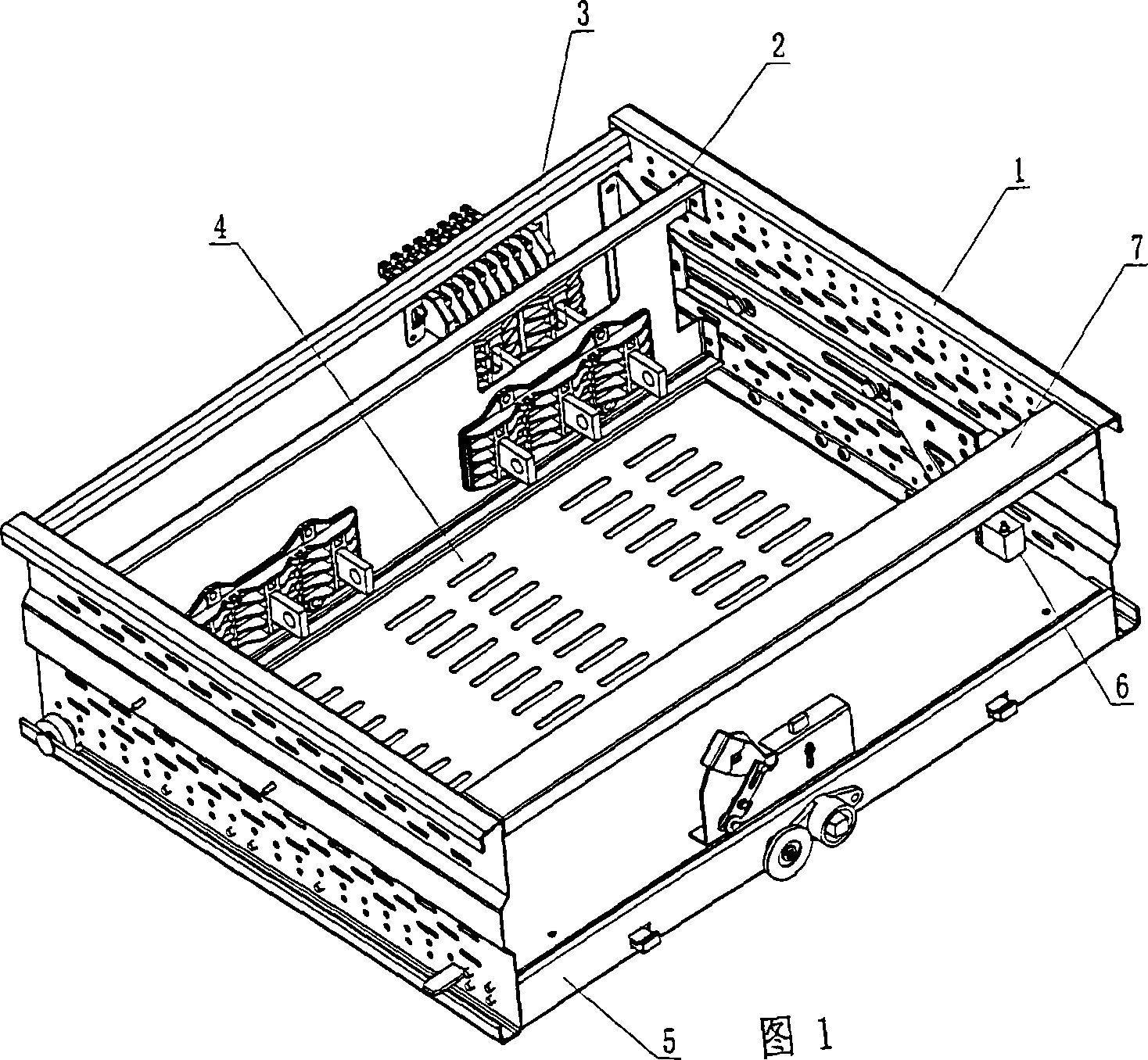

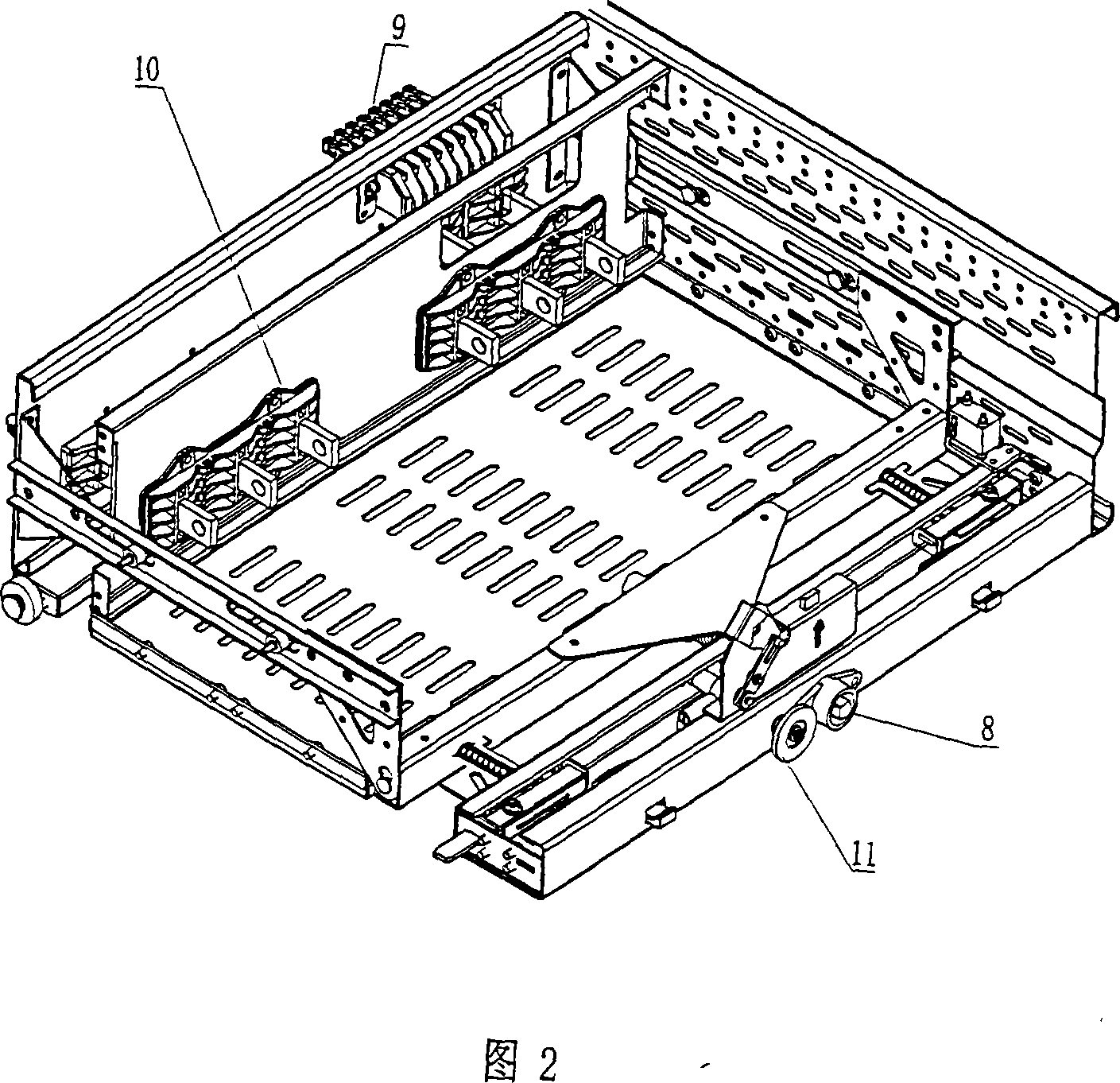

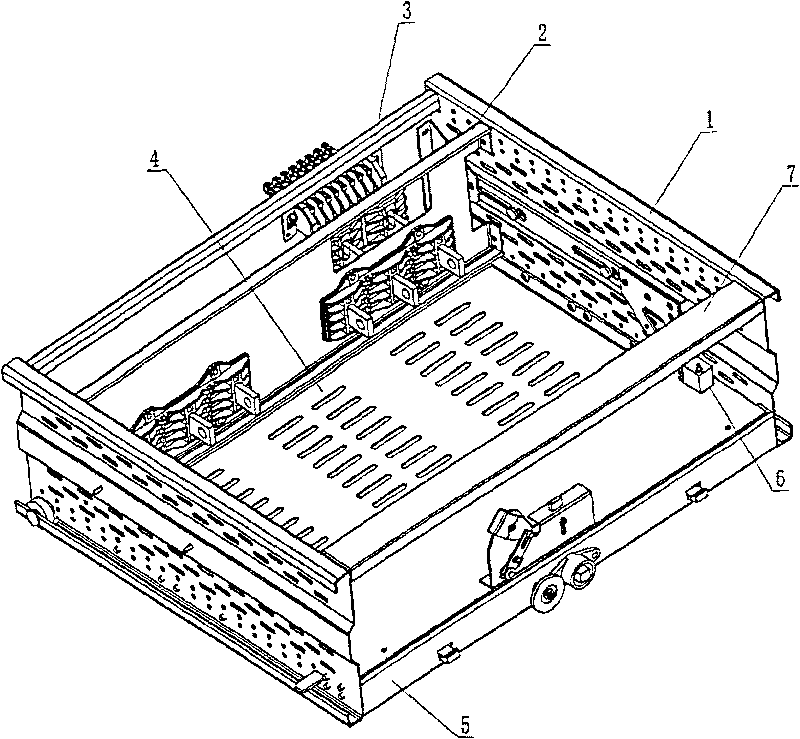

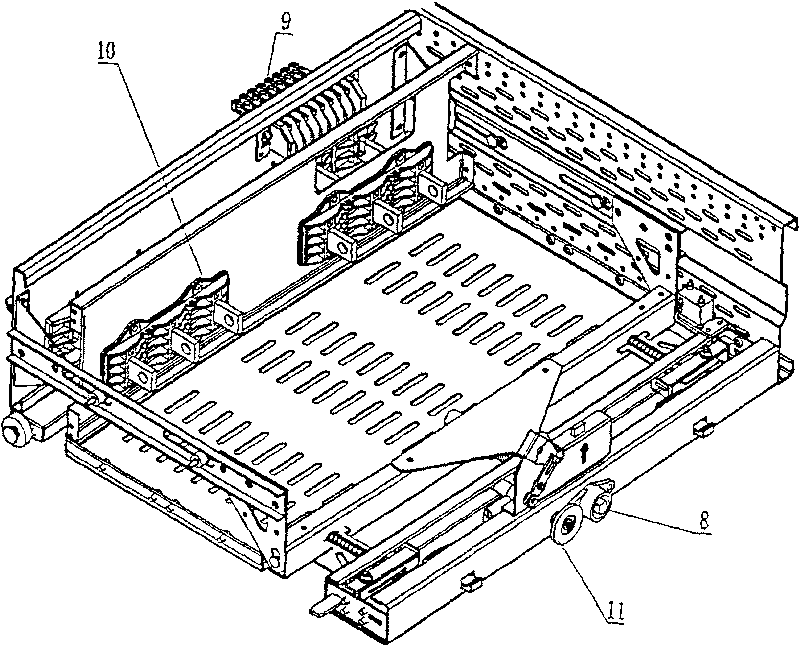

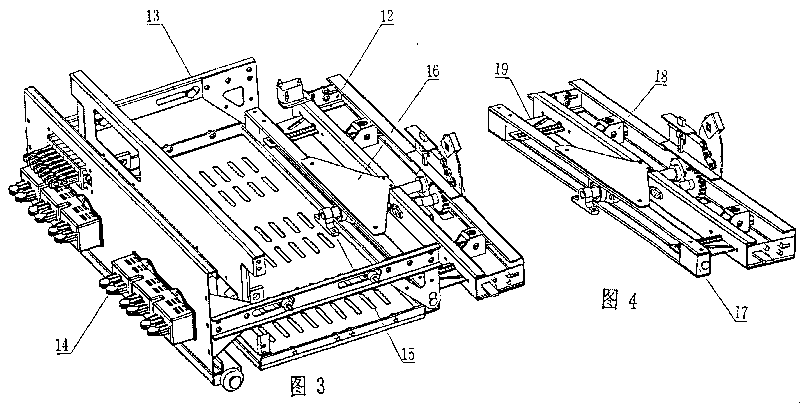

Not-opening door operation tapping unit of low voltage distribution cabinet

InactiveCN101051734AAccurateTo achieve the purpose of not opening the doorSwitchgear with horizontal withdrawalElectricityLow voltage

The unit of low-volatile distribution cabinet includes left and right side plates with double-folded edge, fixed plate, removable back plate, and installation beams being connected. Advantages are: under precondition of not changing original outline structure of unit in draw-out type to reach purpose of operation without opening door. In procedure of operation, function for displaying position requested by national standard is satisfied. Technique of double-folded edge enhances intensity. Thus, thickness of plate is changed to 1.0-1.5mm, and more than 1 / 4 cold steel plate is saved. Electrical connector pieces on moved plate are still aligned to vertical bus precisely. Both way connector (BC) is in module form. Being connected to BC, the conducting strip is changed to forficiform structure from thermal fin type. Thickness of copper plate changes to 2.0mm so as to save material, but still meet requirement of contact insertion and withdraw force, and standard value of temperature rise.

Owner:周金隆 +1

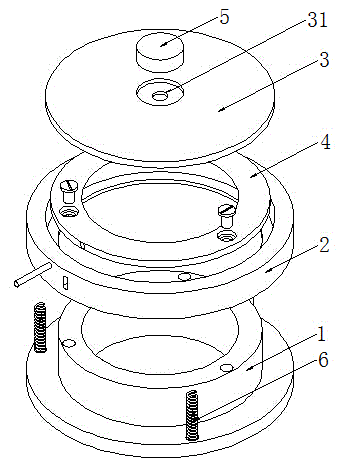

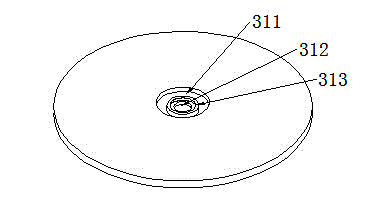

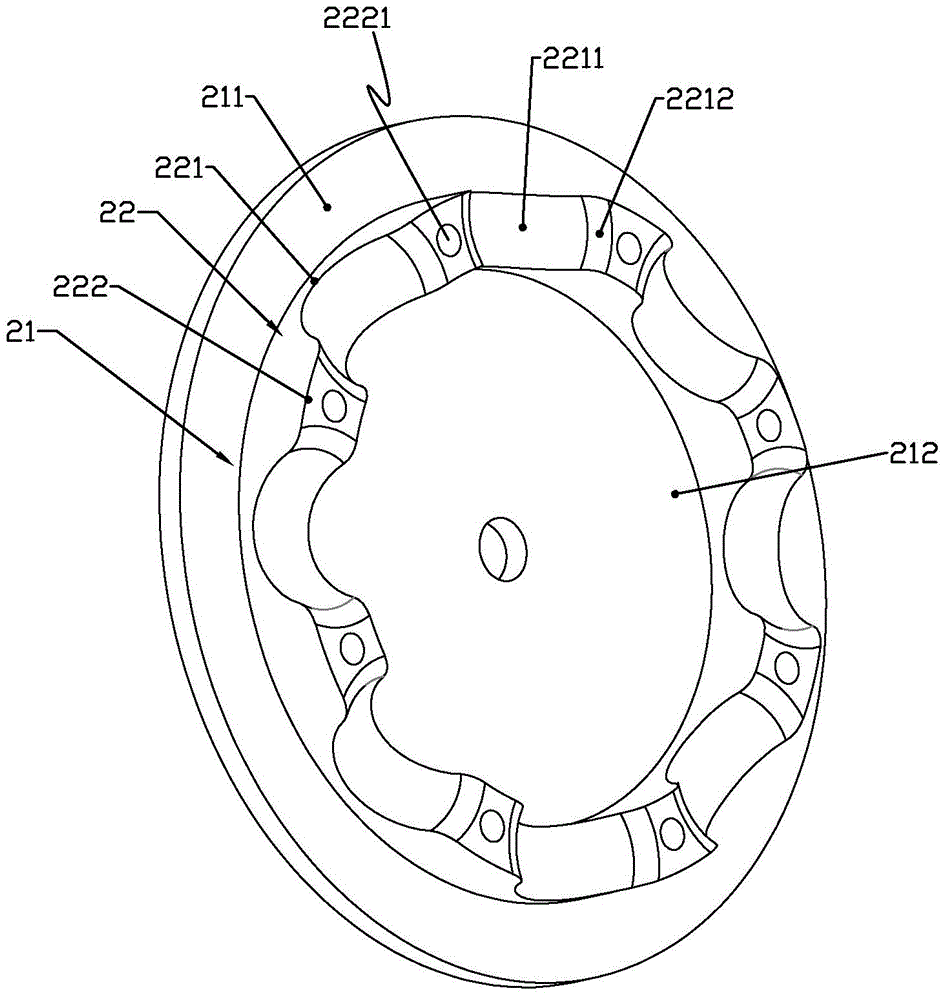

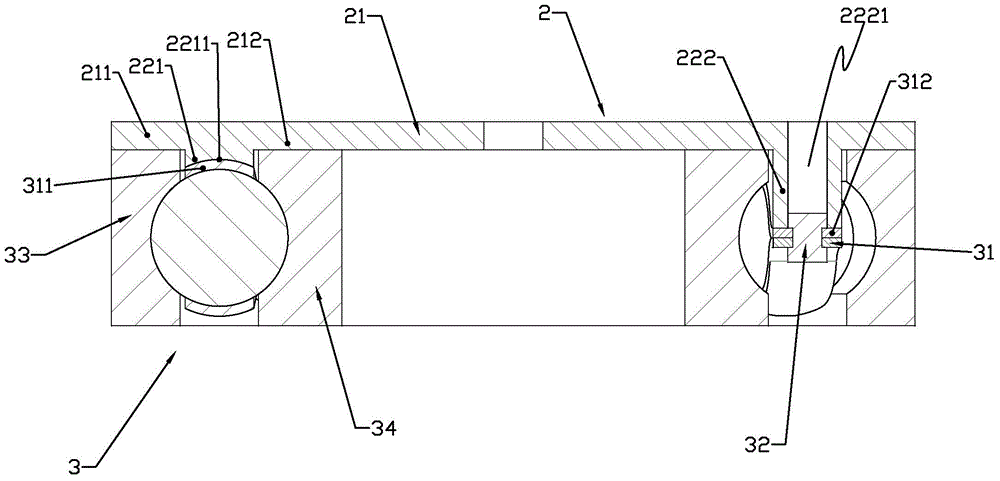

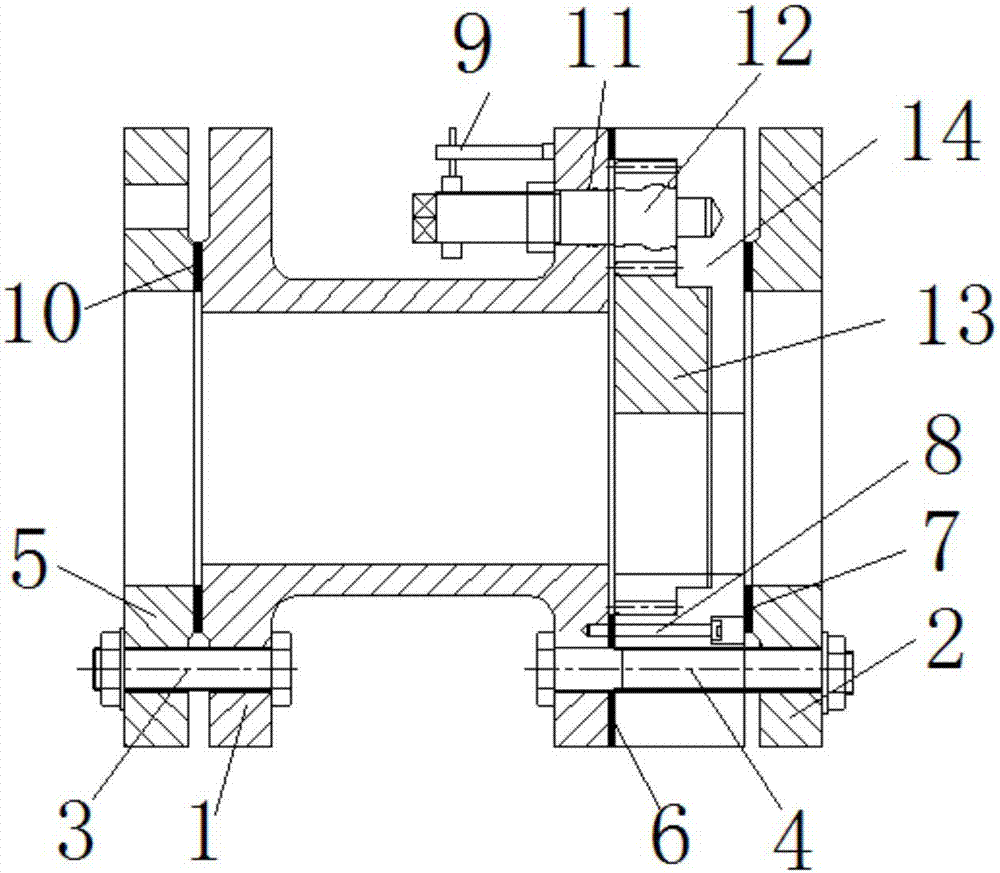

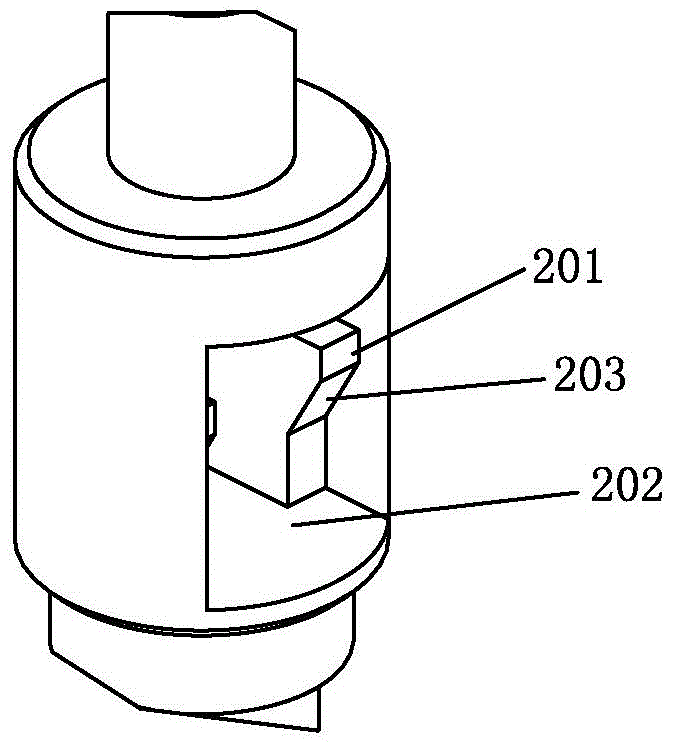

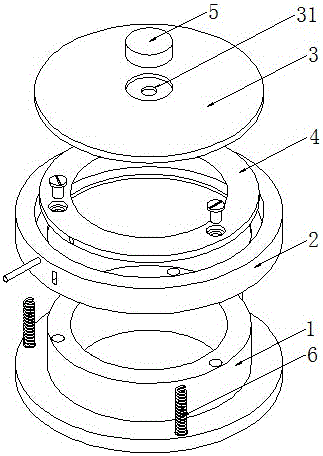

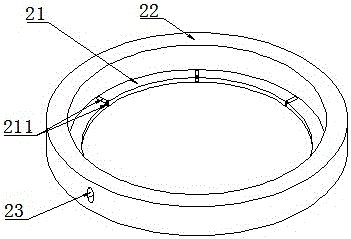

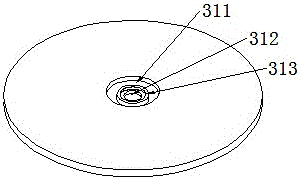

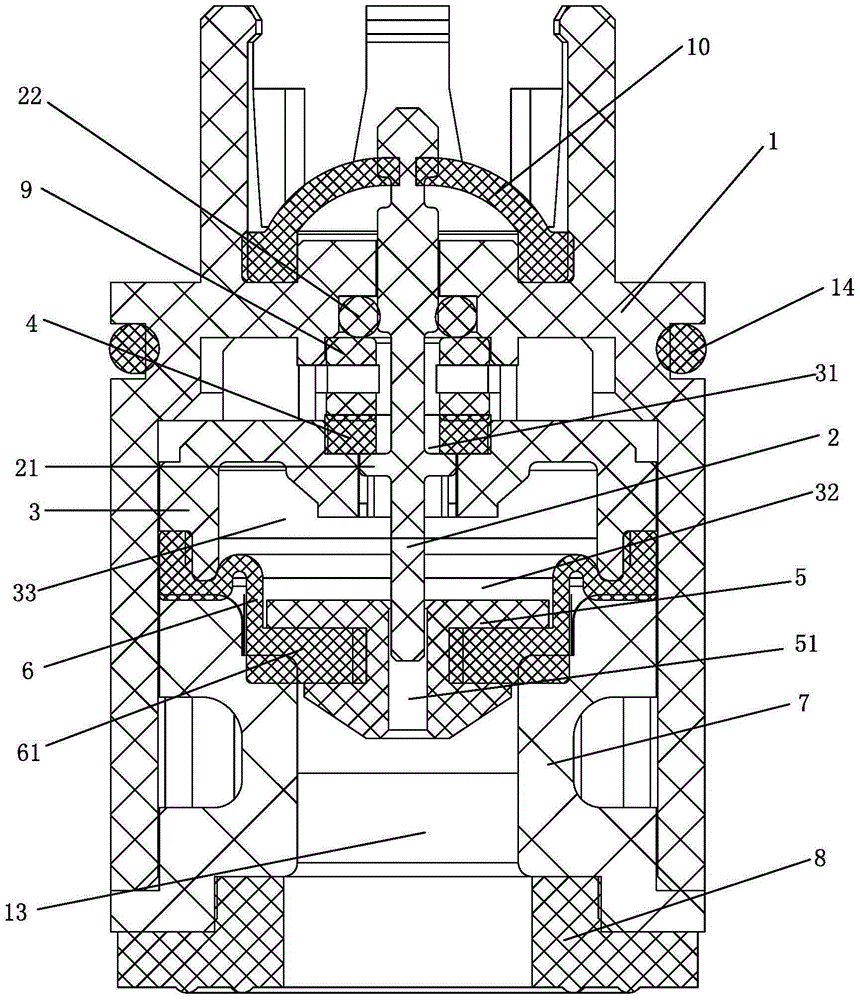

Special die for manufacturing grinding wheel

The invention discloses a special die for manufacturing a grinding wheel. The special die for manufacturing the grinding wheel comprises a bottom die, an outer upper die, an inner upper die, an inner middle die, a core die and an elastic connecting piece, the core die is sleeved in the core hole in the top of the inner upper die, the inner upper die, inner middle die and bottom die are coaxially arranged in sequence from the top to bottom and sleeved in the outer upper die, and the outer upper die is connected with the bottom die through the elastic connecting piece; the inner middle die is firmly connected with a bottom die support barrel, and the outer diameter of the inner middle die is larger than that of the support barrel; the outer upper die is sleeved with the bottom die through an annular clamp at the bottom, and the outer upper die is in limit connection with the inner middle die; a cavity for forming the grinding wheel is arranged among the inner wall of the outer upper die higher than the top surface of the inner upper die, the outer wall of the core die higher than the top surface of the inner upper die and the top surface of the inner upper die. The special die for manufacturing the grinding wheel is capable of reducing the friction consumption of the die, guaranteeing the grinding wheel production quality and prolonging the service life of the die.

Owner:甘虹

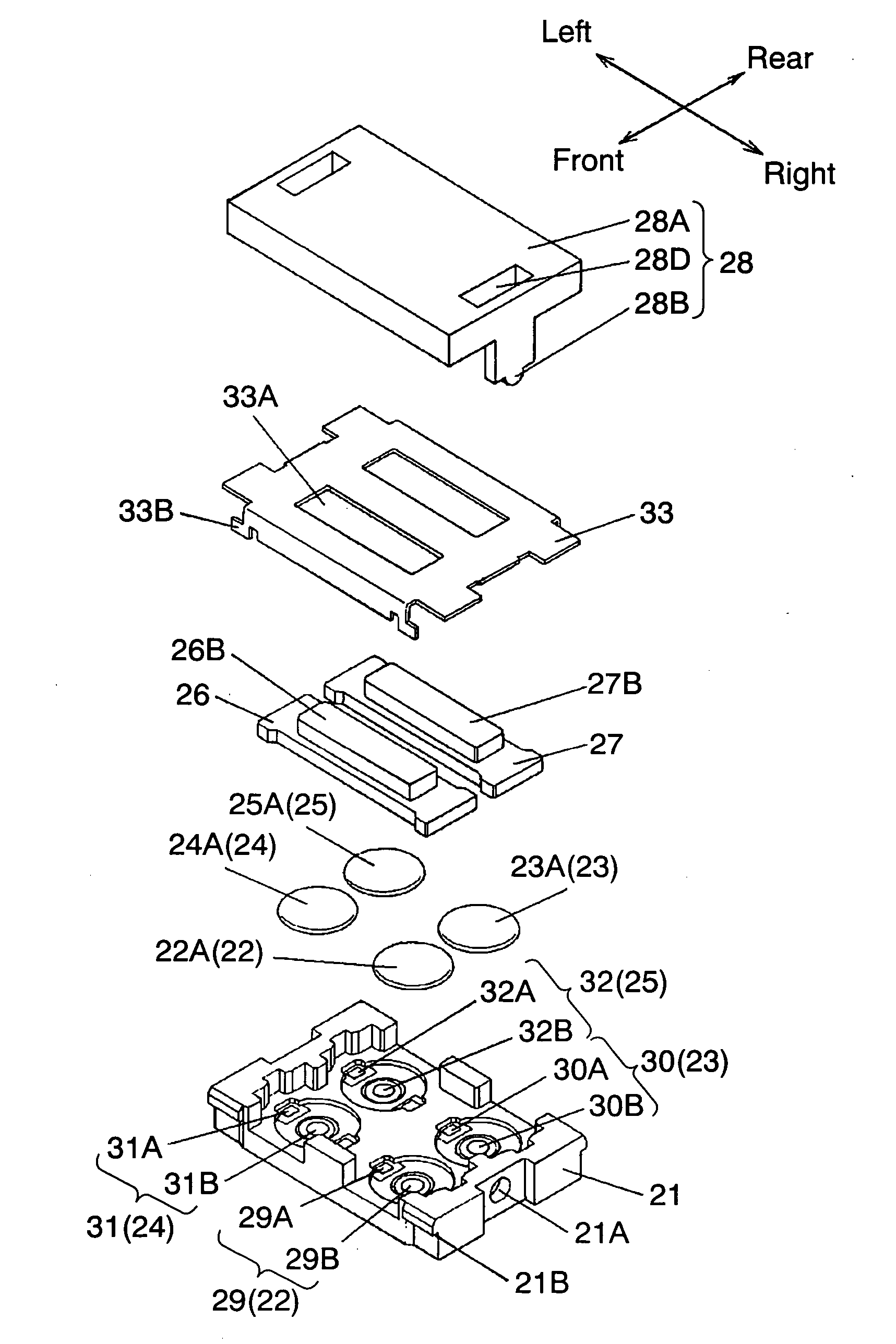

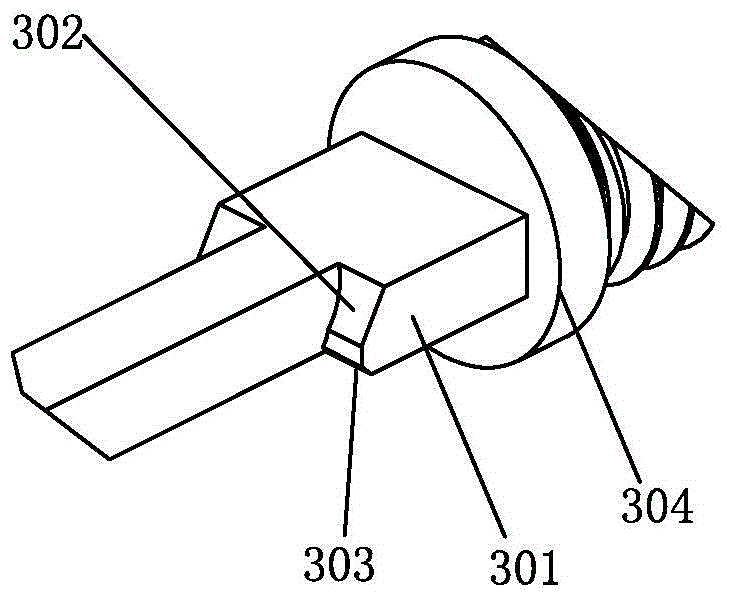

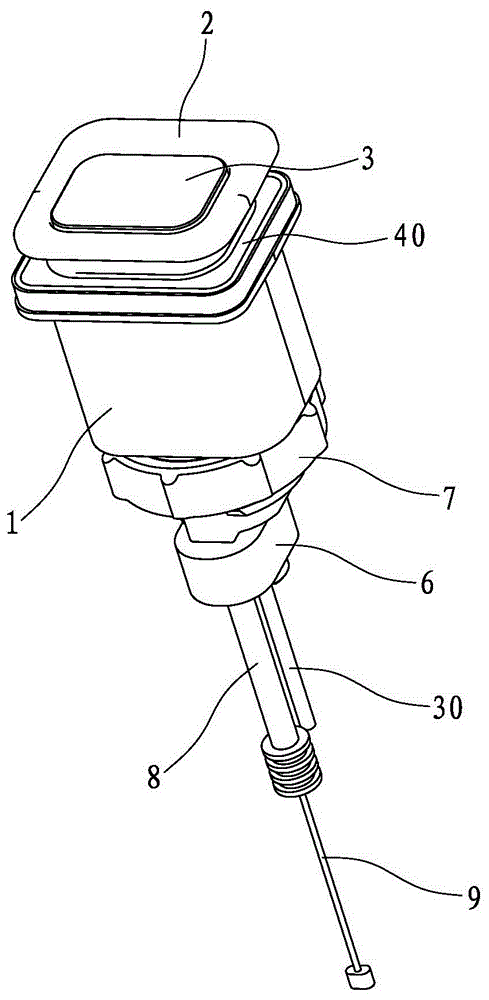

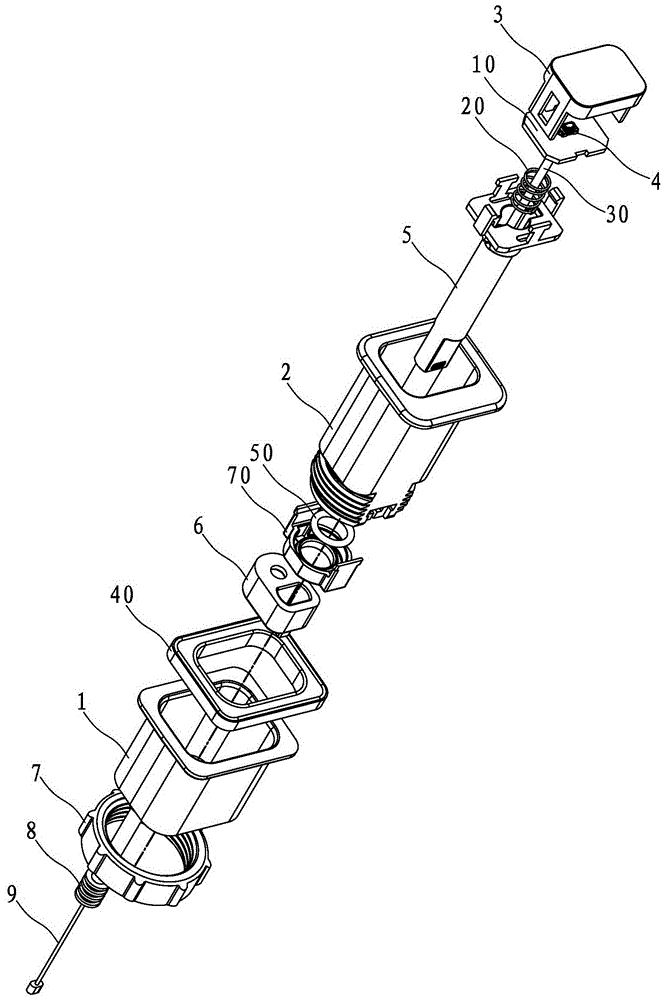

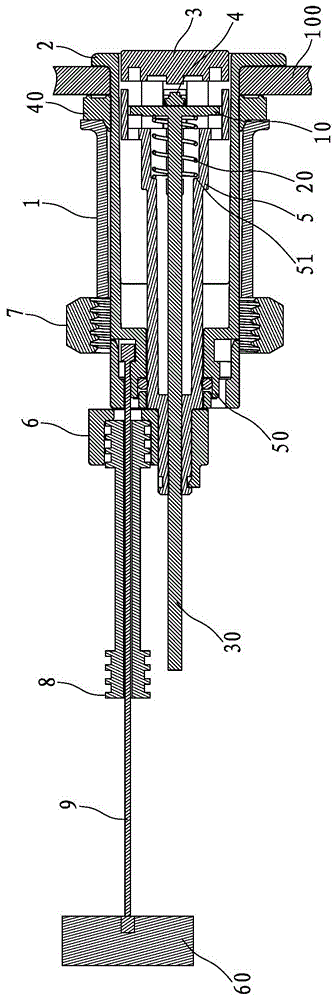

Composite switch

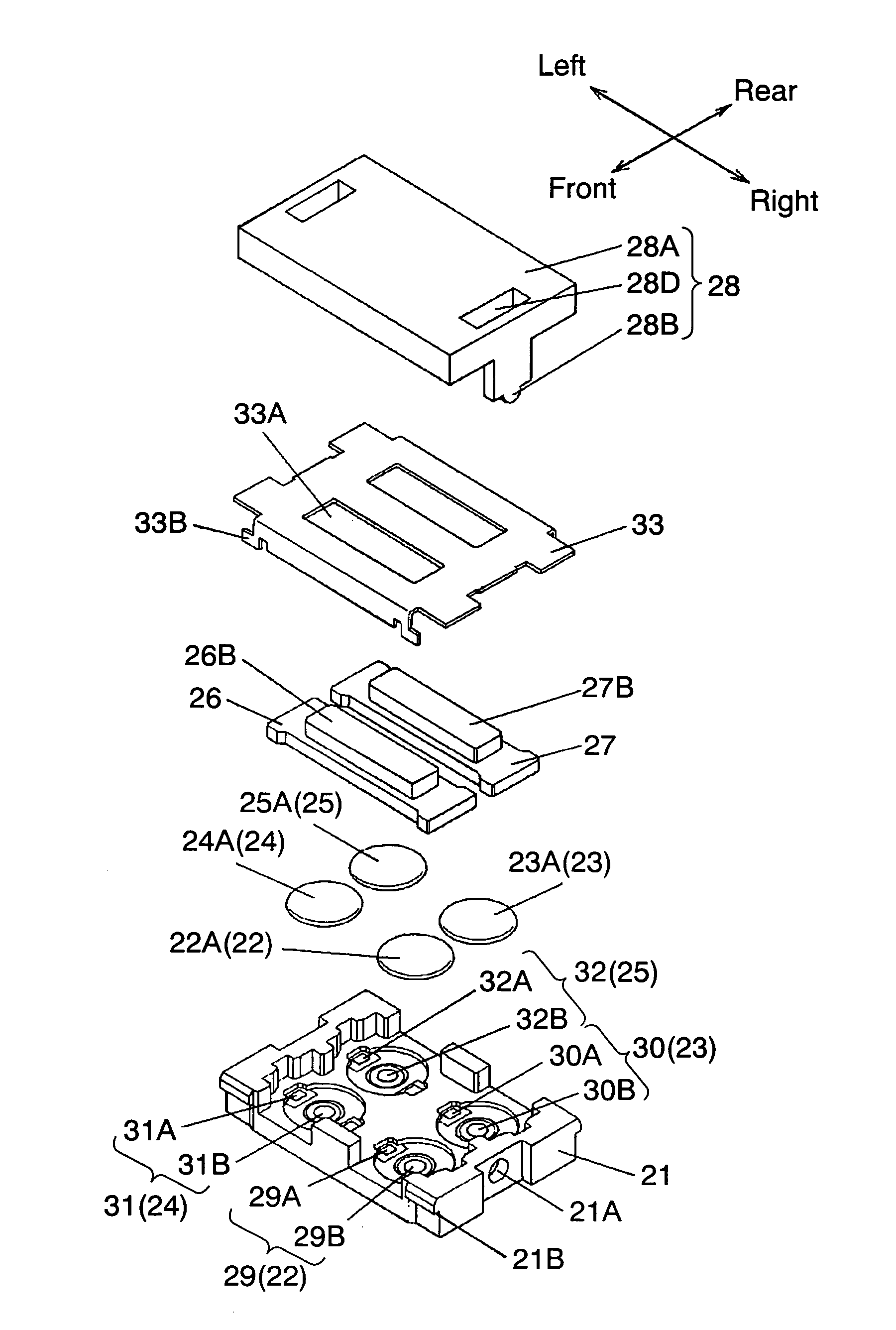

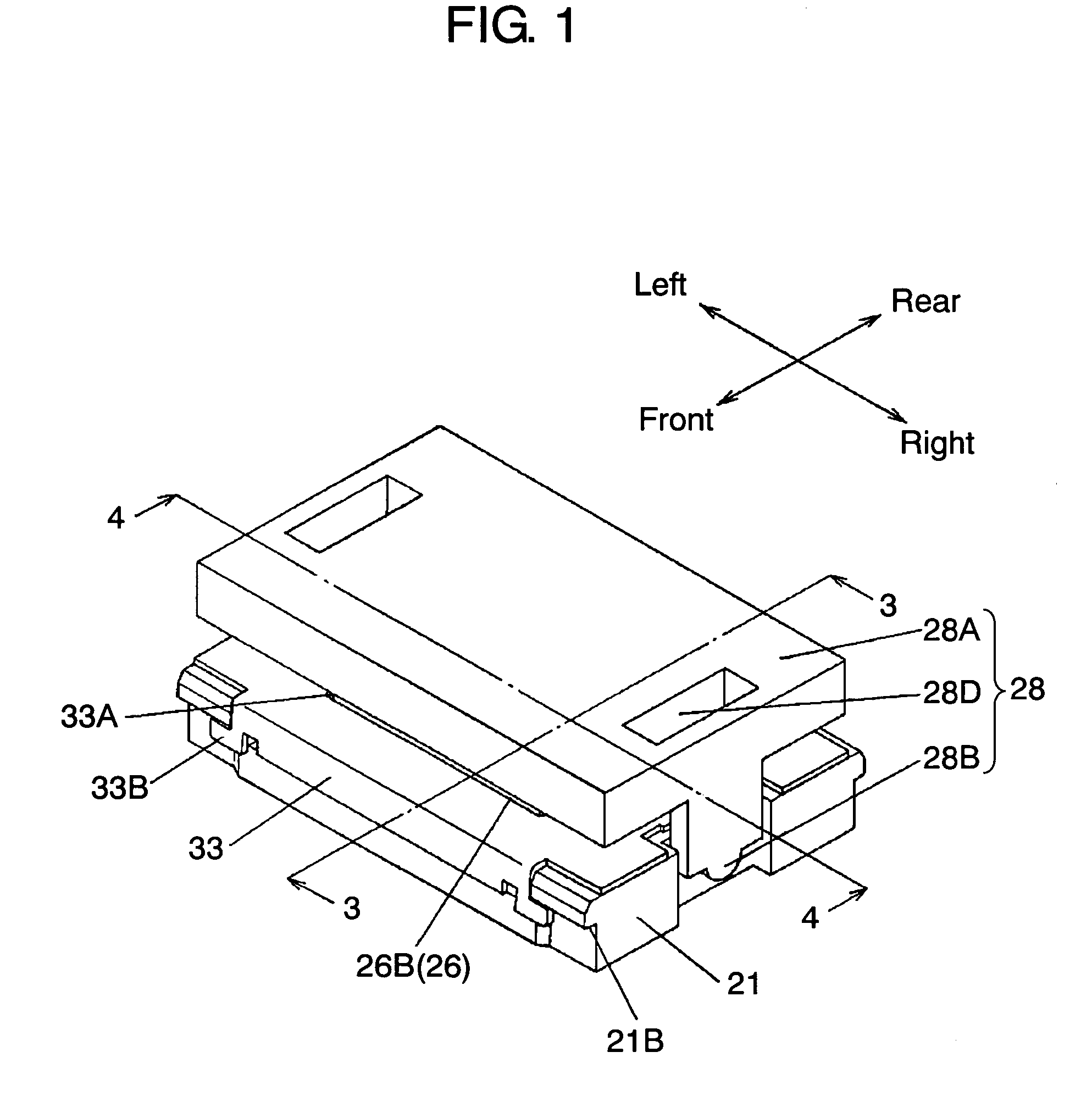

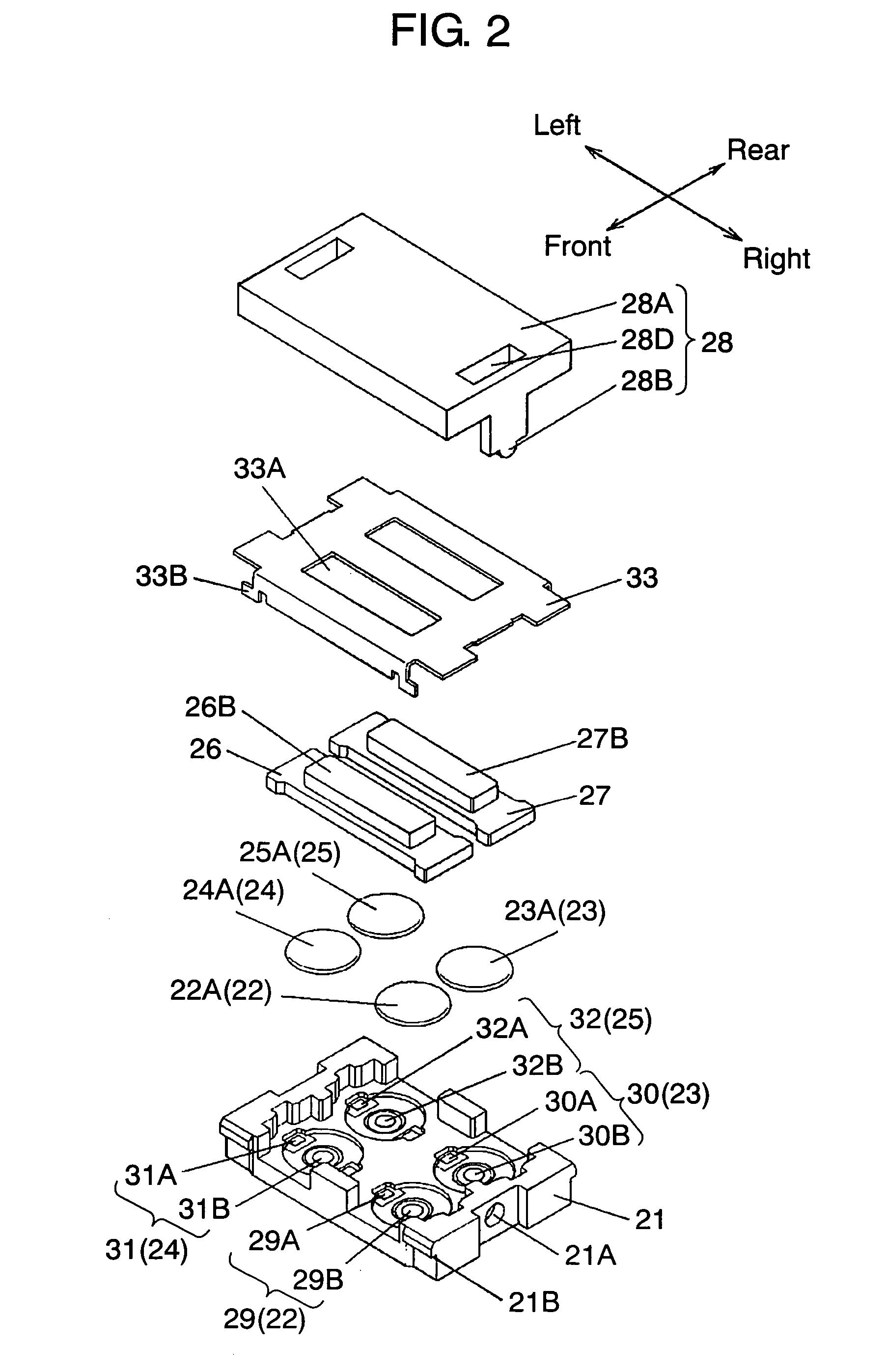

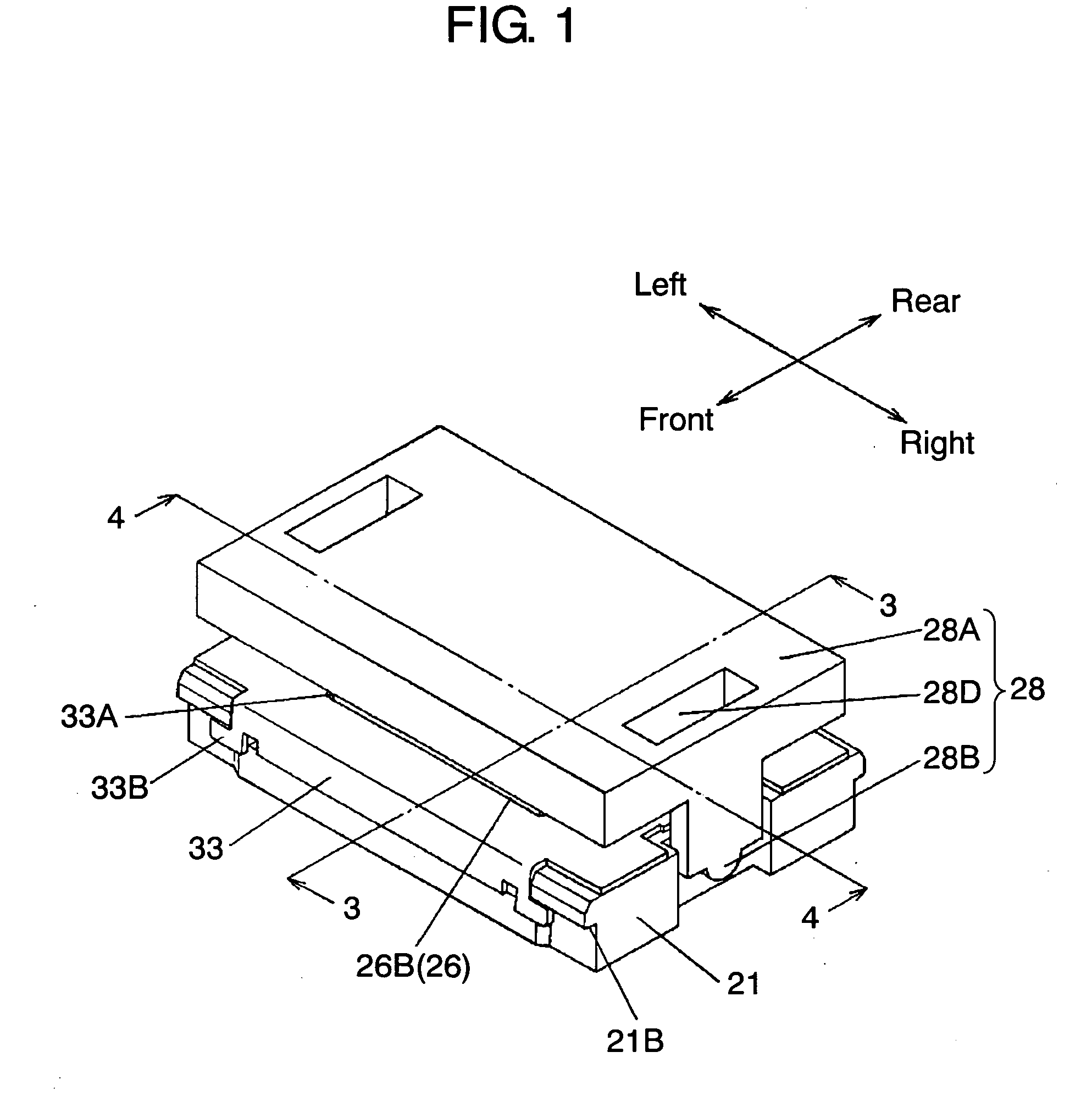

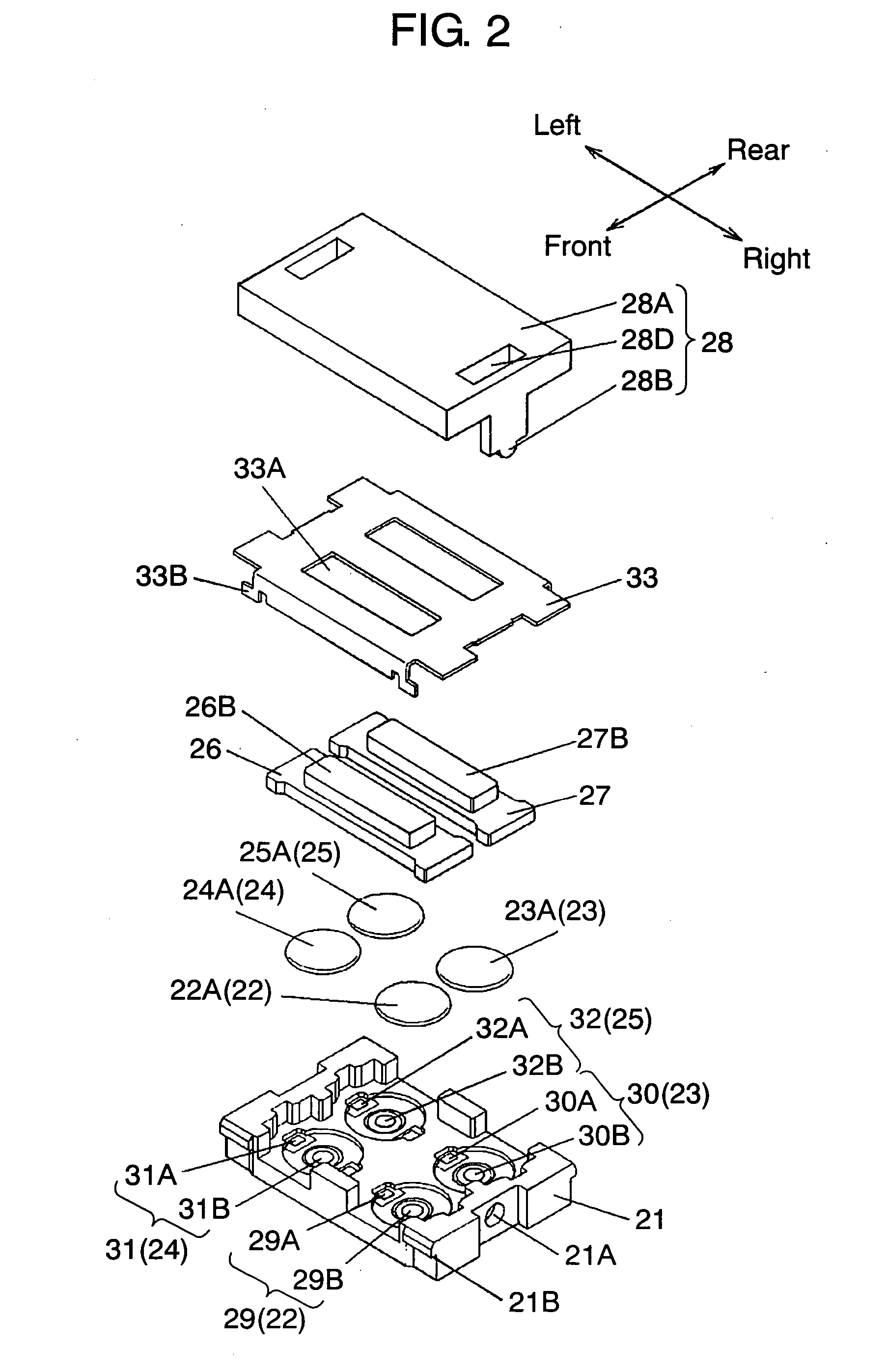

InactiveUS7297881B2Short operating strokeSuppress generationTumbler/rocker switchesSnap-action arrangementsSurface coverElectrical and Electronics engineering

A composite switch having a configuration in which: on the upper part of movable contacts of a first switch to a fourth switch disposed in a case, two driving bodies made of an inelastic insulating material such as polyamide are mounted in parallel to a swing center shaft; an upper surface of the case is covered with a cover having two long holes from which upper parts of the two driving bodies protrude; and the two driving bodies are pressed by an operation body, made of an inelastic insulating resin, which is swingably supported. With a composite switch having this configuration, an operation stroke is short and the generation of noise can be suppressed.

Owner:PANASONIC CORP

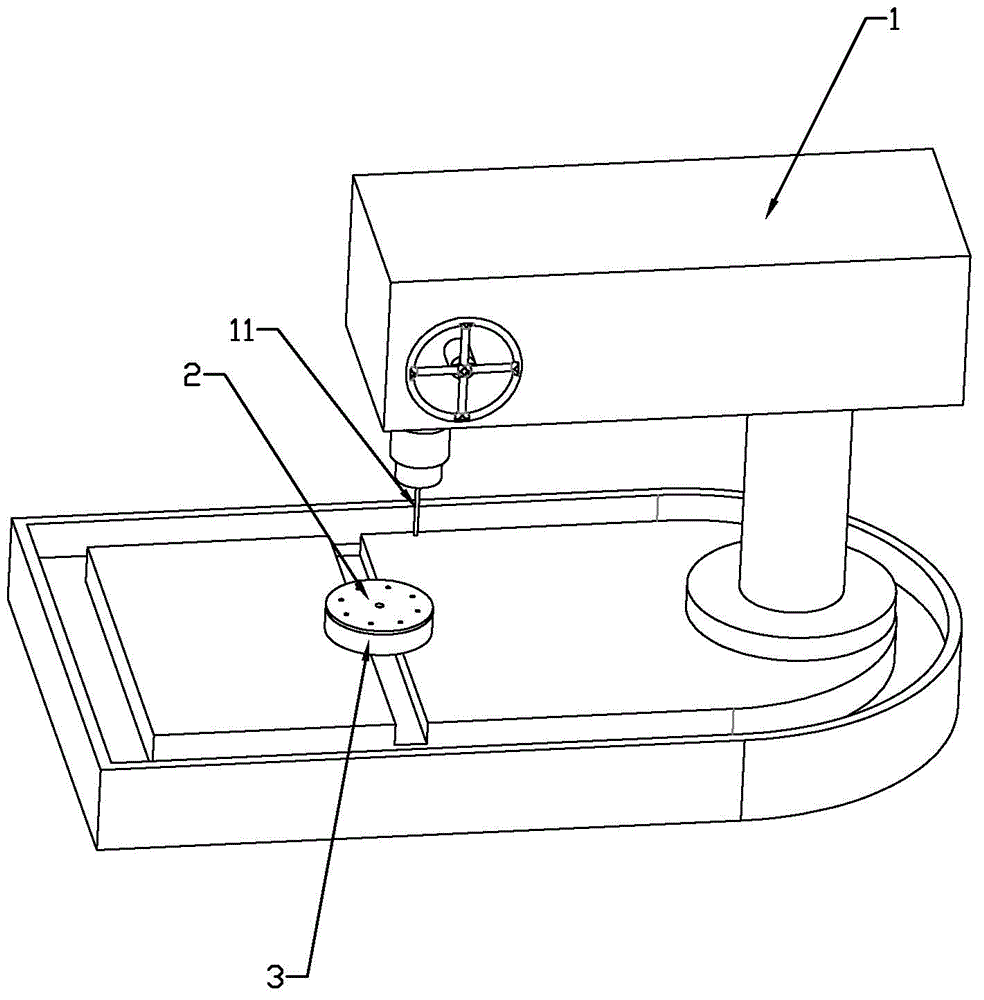

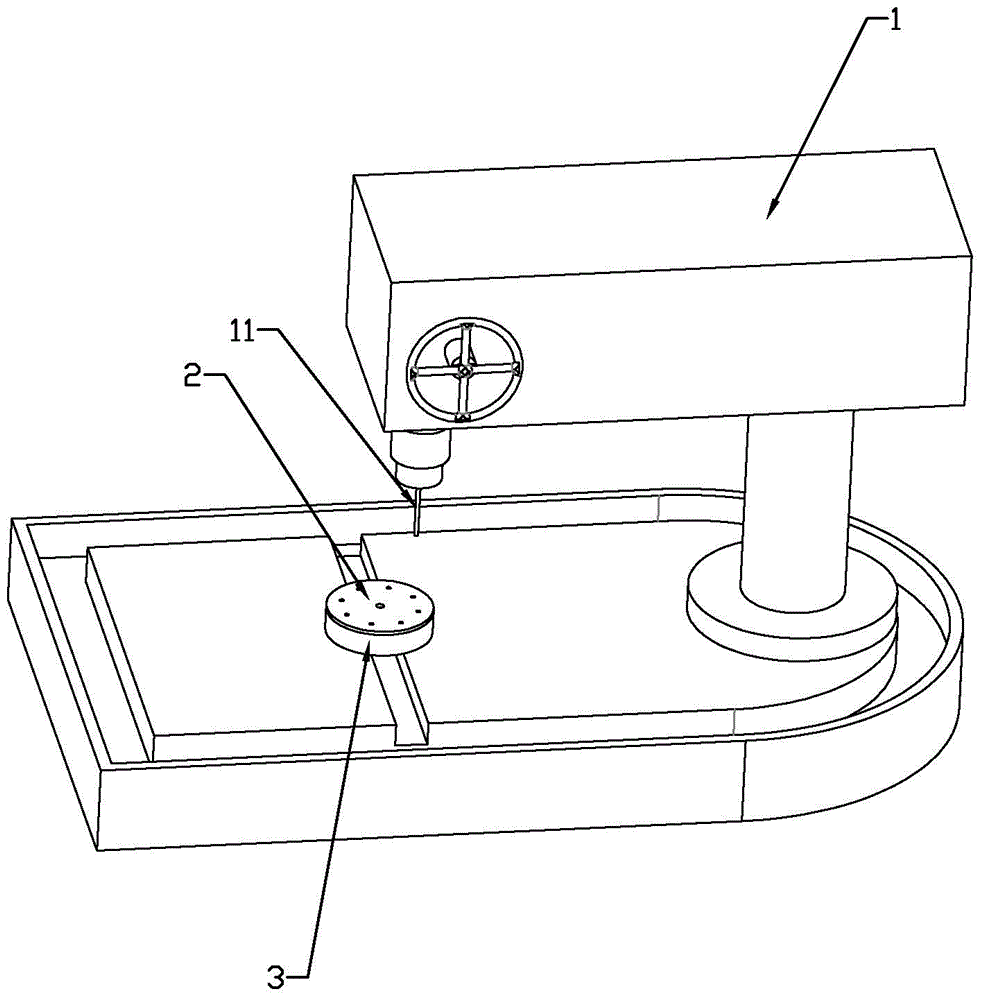

Deep groove ball bearing retainer dismantling method

The invention relates to a deep groove ball bearing retainer dismantling method. A retainer of a deep groove ball bearing is positioned and supported by means of an auxiliary bearing dismantling tool so as to be prevented from rotating and then is placed on a working table of a drilling machine, drilling cuttings on the heads of all rivets of the retainer of the deep groove ball bearing are removed by means of a drill bit of the drilling machine, and thus two retainer bodies of the retainer of the deep groove ball bearing are separated to complete dismantling. The deep groove ball bearing retainer dismantling method has the advantages that dismantling operation is easy and convenient, all components of the bearing are prevented from being damaged, accurate bearing disassembly analysis is achieved, and reutilization of qualified components of the bearing is achieved.

Owner:C&U CO LTD

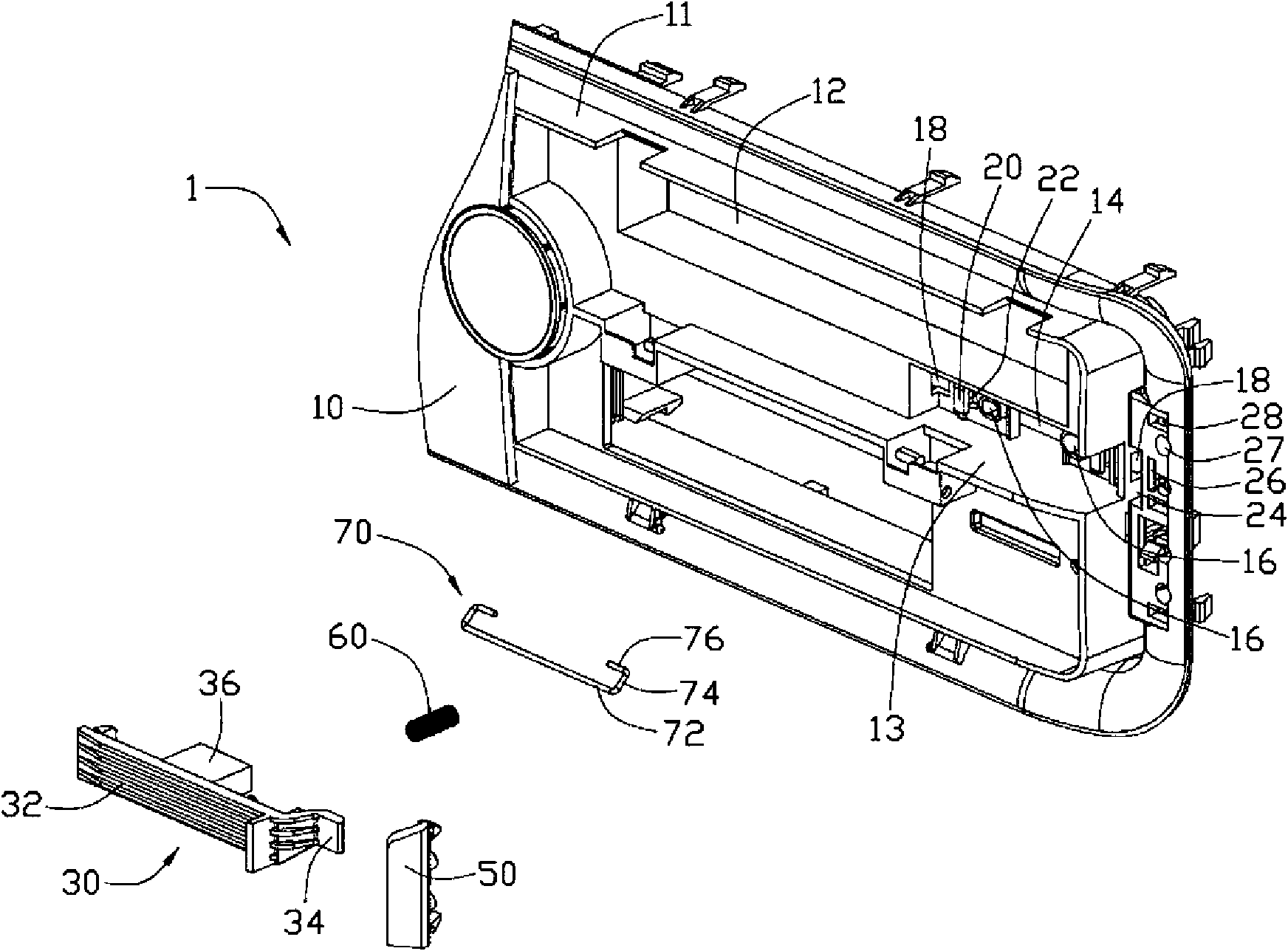

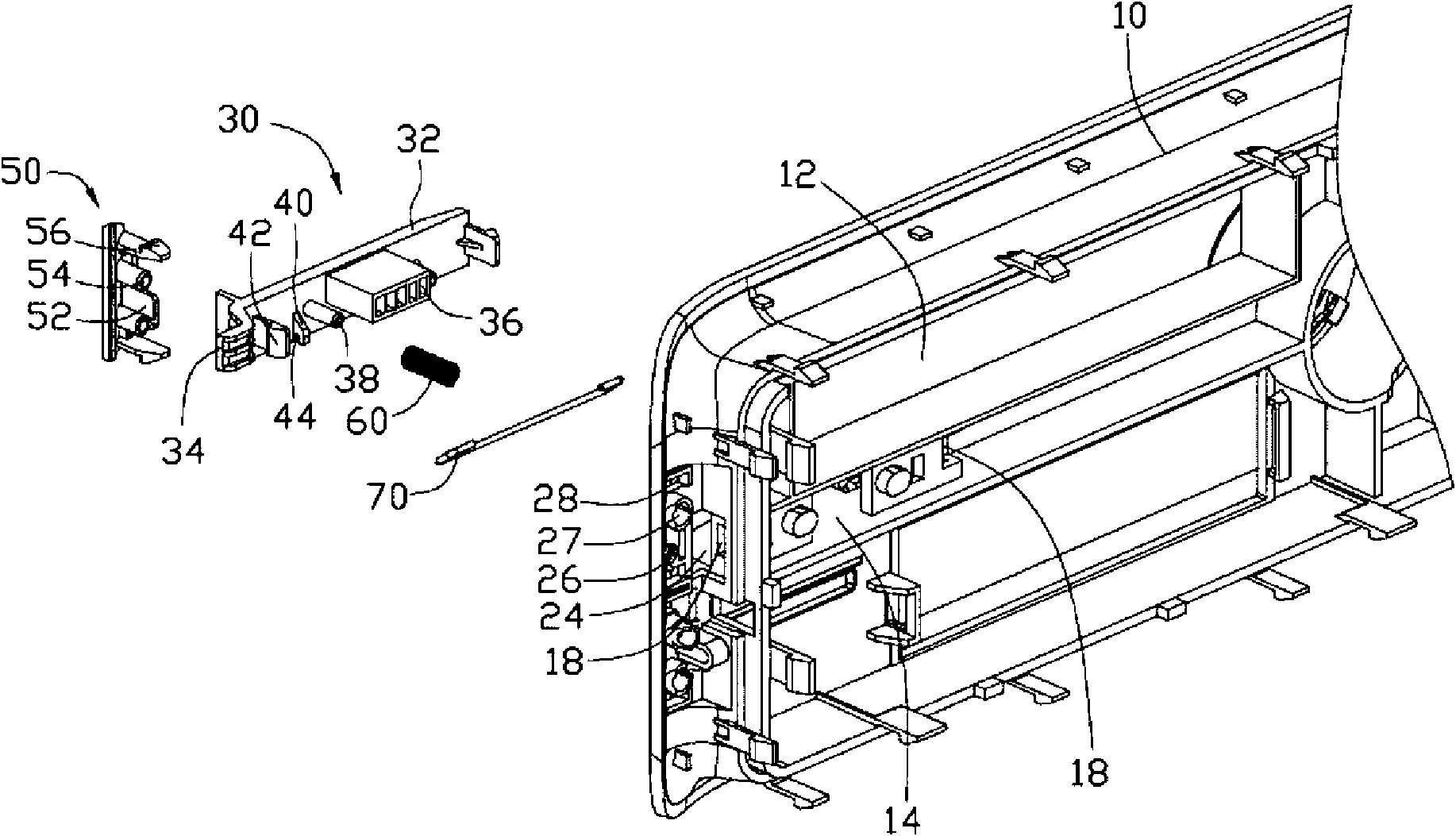

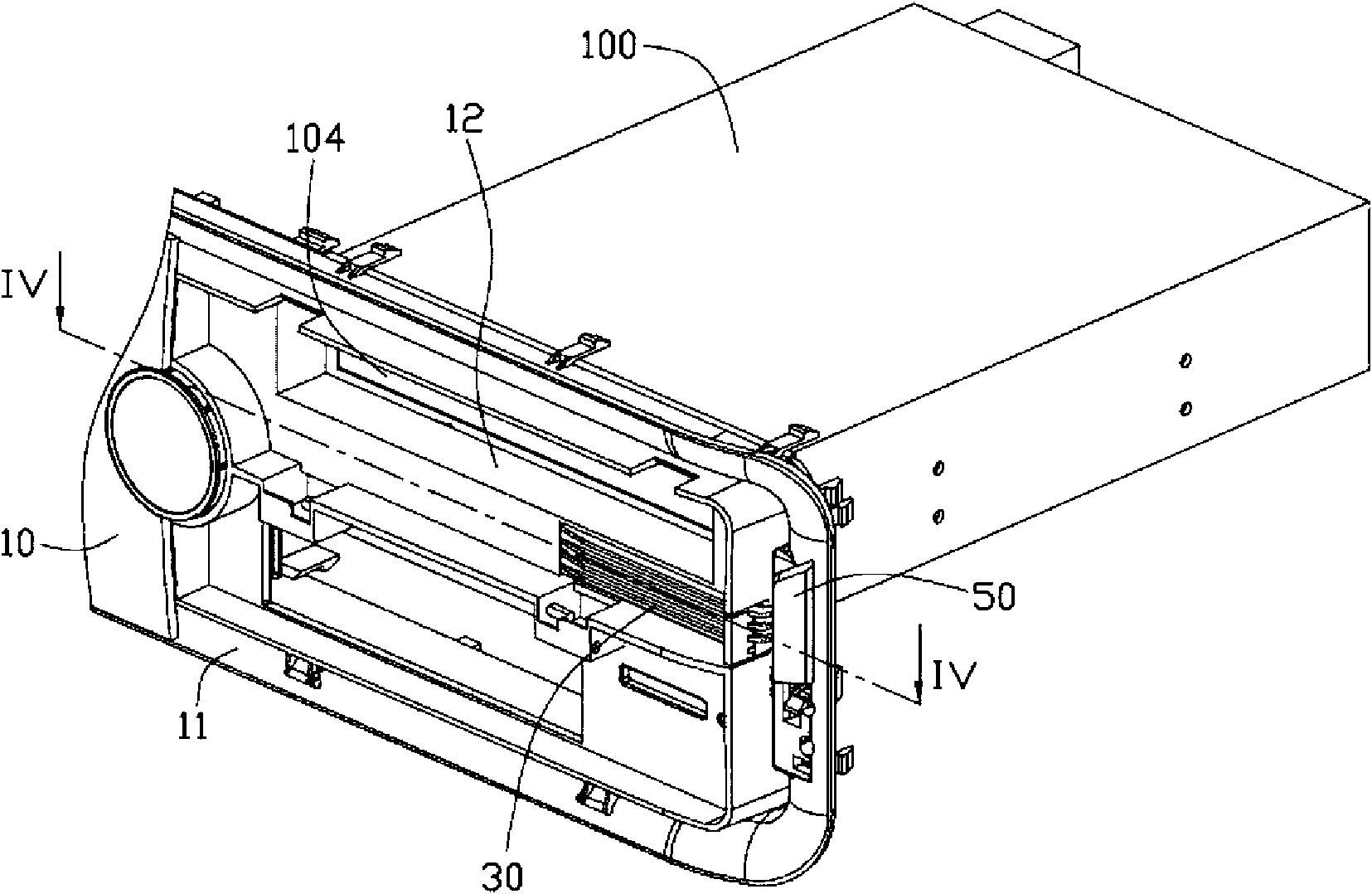

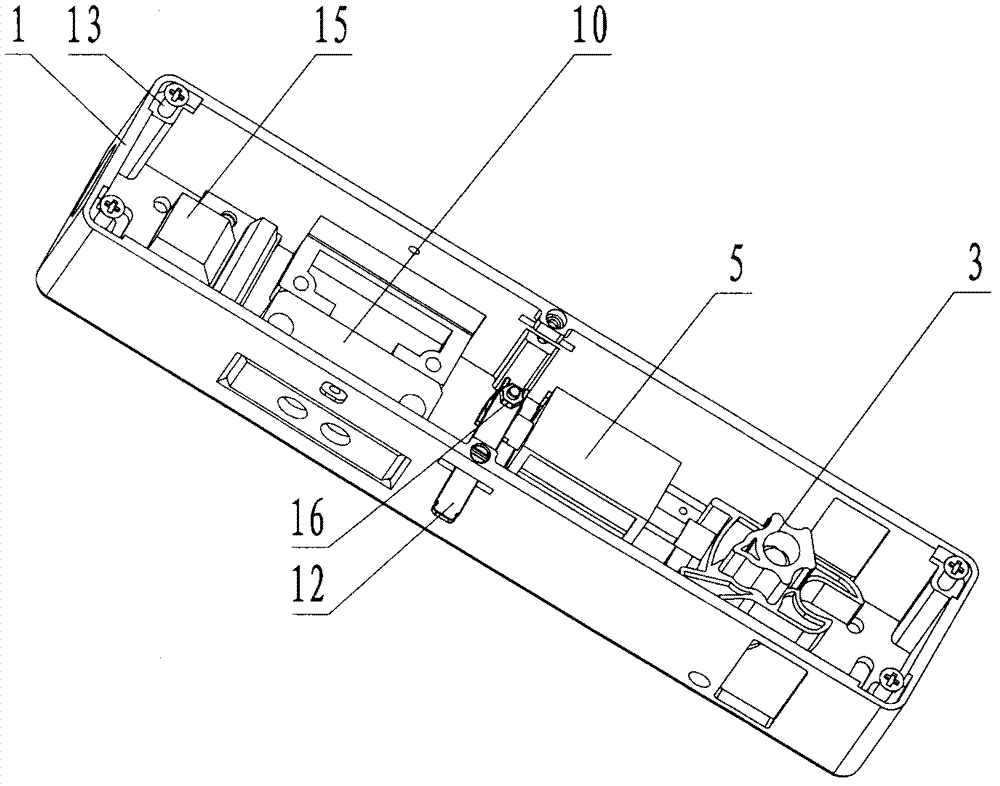

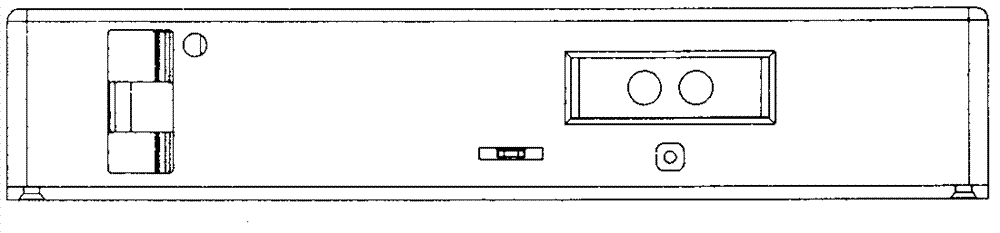

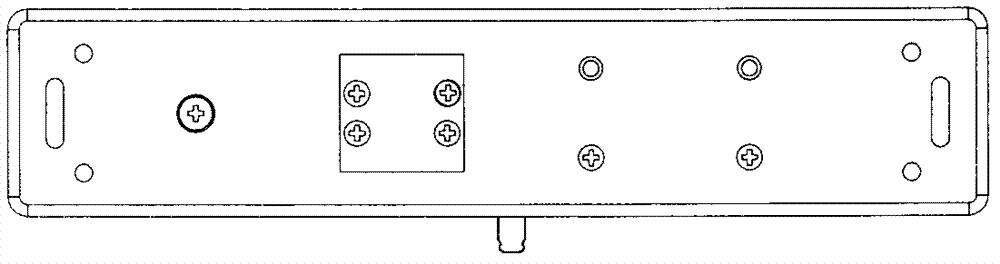

Computer panel key device

InactiveCN102082039AShort operating strokeTo achieve aesthetic effectContact operating partsRecord information storageKey pressingMechanical engineering

The invention relates to a computer panel key device, comprising a panel, a pressing piece, an elastic piece and a linkage piece. The pressing piece is mounted on the panel to trigger a CD driver button; the elastic piece is used for resetting the pressing piece, and the linkage piece is arranged between the pressing piece and the panel so that the pressing piece can make translational motion relative to the panel. When the computer panel key device is mounted on a computer case with a CD driver, the pressing piece faces to the CD driver button; when the pressing piece is pressed, the pressing piece is driven by the linkage piece to make translational motion relative to the panel and trigger the CD driver button to reduce the operation process of the pressing piece; and the design of the pressing piece is matched with the appearance of the panel to reach the effect of attractive appearance.

Owner:HONG FU JIN PRECISION IND WUHAN CO LTD +1

Throttle regulation valve and production process thereof

The invention discloses a throttle regulation valve. The throttle regulation valve comprises a valve body, wherein the left end of the valve body is connected with a first companion flange through a first bolt assembly; a gear stand is mounted at the right end of the valve body through a hexagon socket screw; a driven gear is mounted in the middle of the interior of the gear stand and is in meshed connection with a driving gear; and the driving gear is positioned on the upper side of the interior of the gear stand. According to the throttle regulation valve, the driving gear is operated through rotation to drive the driven gear, so that the position, corresponding to an eccentric hole in the gear stand, of the driven gear is changed, a channel, in which a medium flows, in a pipeline is changed, and accordingly, the flow rate in the pipeline is changed; a striking switch sign scale line is arranged on a switch indicator, and throttling can be visually operated and controlled through the switch indicator; as the throttle regulation valve is designed by adoption of the gear transmission principle, the throttle regulation valve is particularly steady and quick in flow regulation process; and the operation is short in journey and convenient and labor-saving.

Owner:NANTONG J RELIANCE VALVES COMPANY

Composite switch

InactiveUS20070131531A1Suppresses noise generationSuppress generationTumbler/rocker switchesSnap-action arrangementsPolyamideEngineering

A composite switch having a configuration in which: on the upper part of movable contacts of a first switch to a fourth switch disposed in a case, two driving bodies made of an inelastic insulating material such as polyamide are mounted in parallel to a swing center shaft; an upper surface of the case is covered with a cover having two long holes from which upper parts of the two driving bodies protrude; and the two driving bodies are pressed by an operation body, made of an inelastic insulating resin, which is swingably supported. With a composite switch having this configuration, an operation stroke is short and the generation of noise can be suppressed.

Owner:PANASONIC CORP

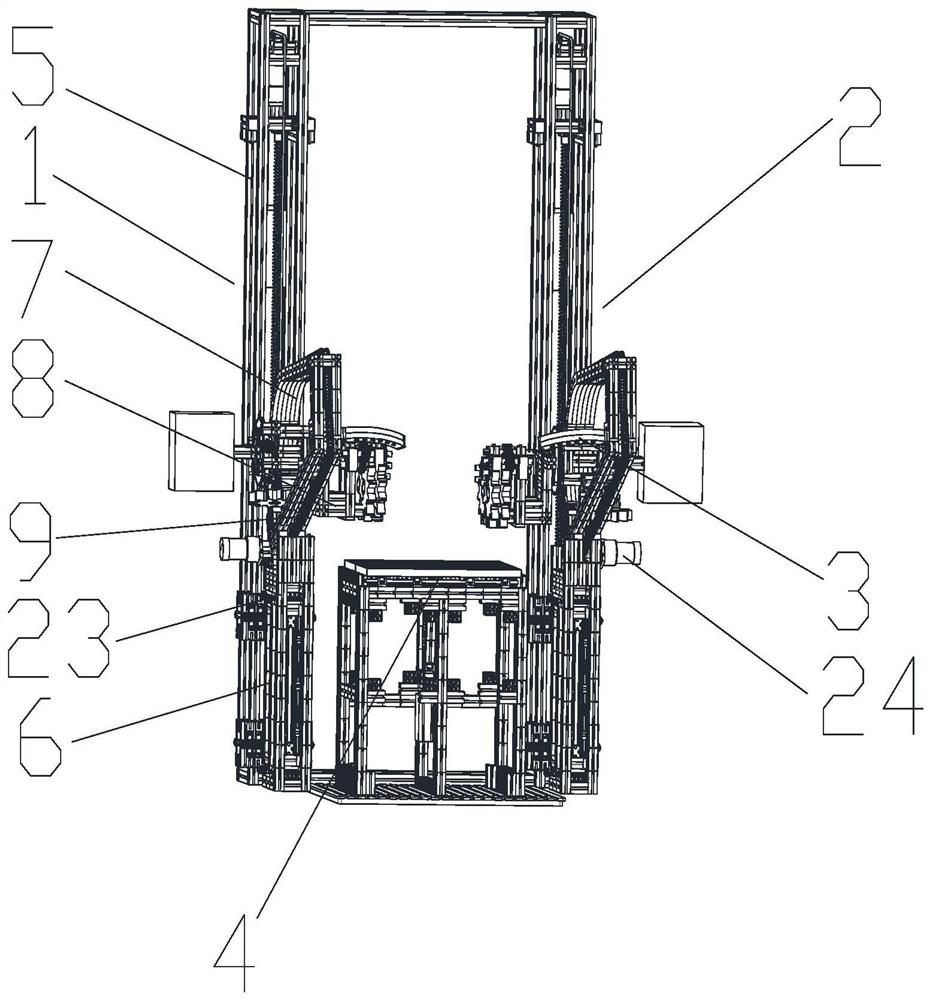

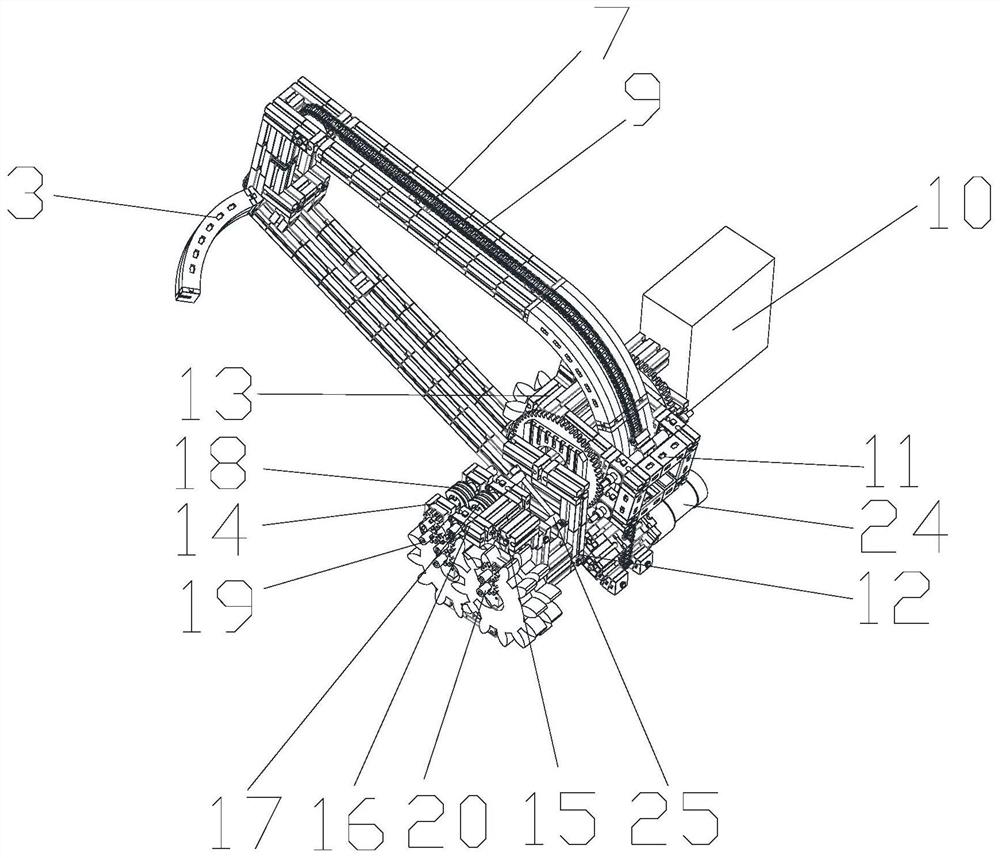

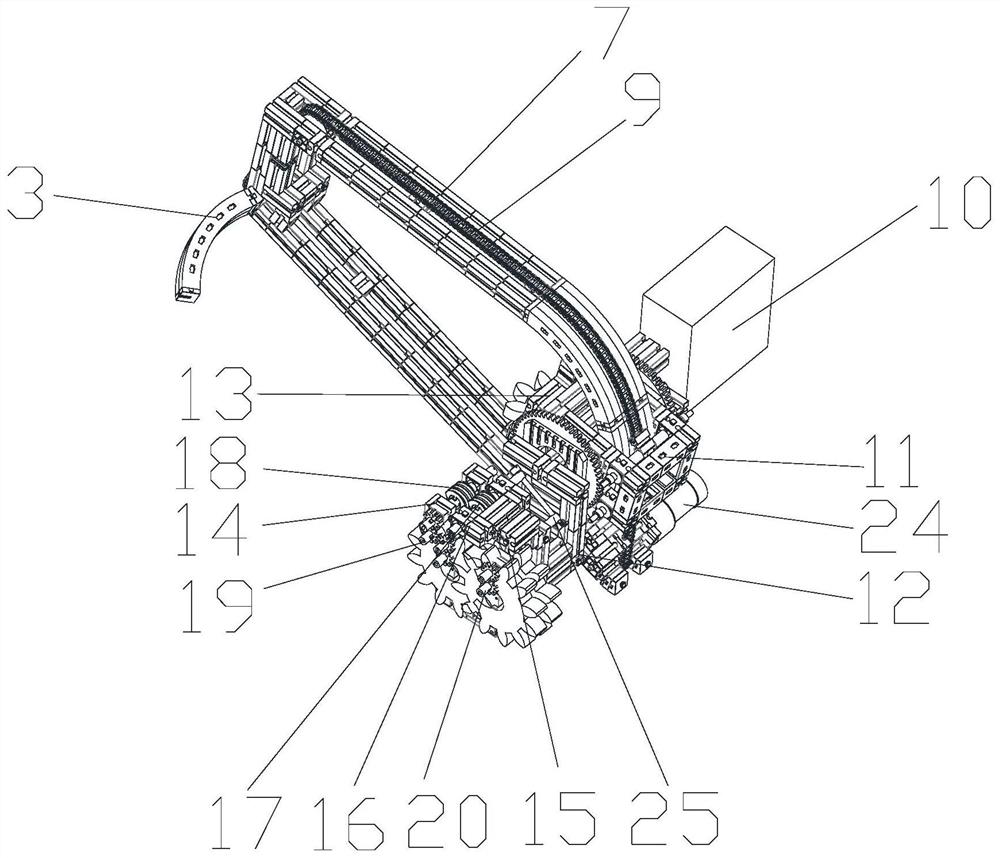

Auxiliary frame for putting on and taking off of sleeveless sweater

ActiveCN112056903ASolve the arms crossed raiseSolving the Difficulties of Pulldowns with Curved ArmsApparel holdersControl theoryChain drive

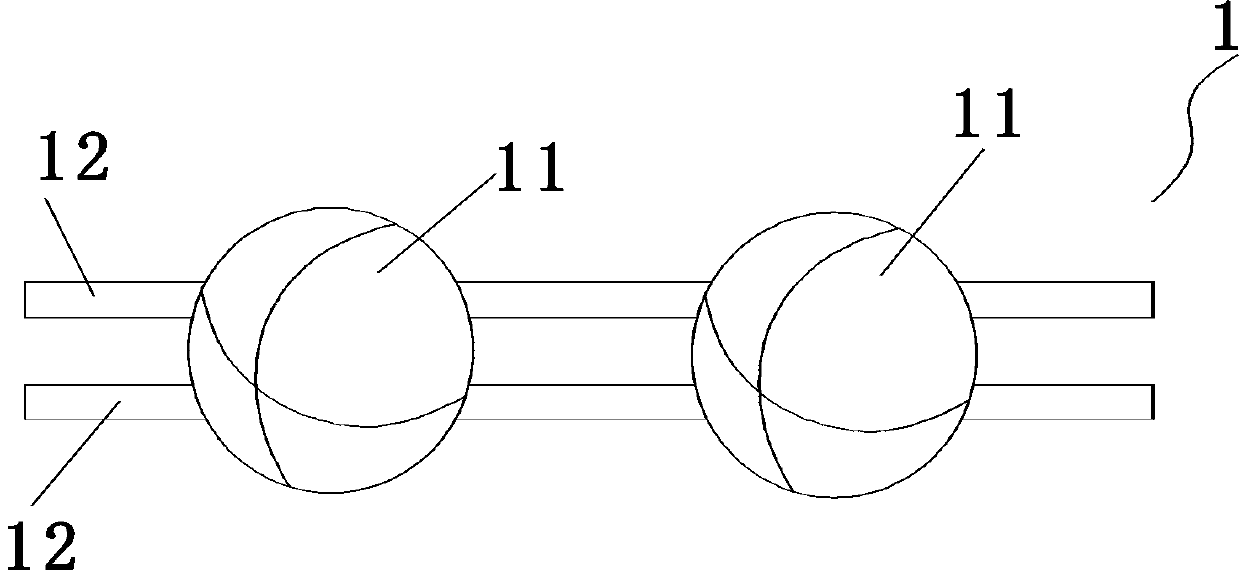

The invention relates to an auxiliary frame for putting on and taking off of a sleeveless sweater. The auxiliary frame comprises a first auxiliary frame and a second auxiliary frame which are symmetrically arranged, wherein the first auxiliary frame comprises a fixed support, a sliding block support is arranged in the height direction of the fixed support in a sliding mode, an arc-shaped front pull guide rail is arranged on the sliding block support, a manipulator is arranged on the front pull guide rail in a sliding mode, and a transmission chain used for driving the manipulator to slide is further arranged on the front pull guide rail; the manipulator comprises a sliding seat in transmission connection with the transmission chain, a rotating arm rotationally arranged on the sliding seat,a finger clamp mechanism fixed on the rotating arm and a rotating arm motor fixed on the sliding seat, the rotating arm motor is used for driving the rotating arm to rotate, and the finger clamp mechanism comprises a pressing support and a clothes gathering support which are oppositely arranged; a pressing plate is rotationally arranged on the pressing support, a first roller is rotationally arranged on the pressing plate, a second roller matched with the first roller to press the sleeveless sweater is rotationally arranged on the clothes gathering support, and a clothes gathering motor usedfor driving the second roller to rotate is further arranged on the clothes gathering support; and the structure of the second auxiliary frame is the same as that of the first auxiliary frame.

Owner:CHANGZHOU INST OF TECH

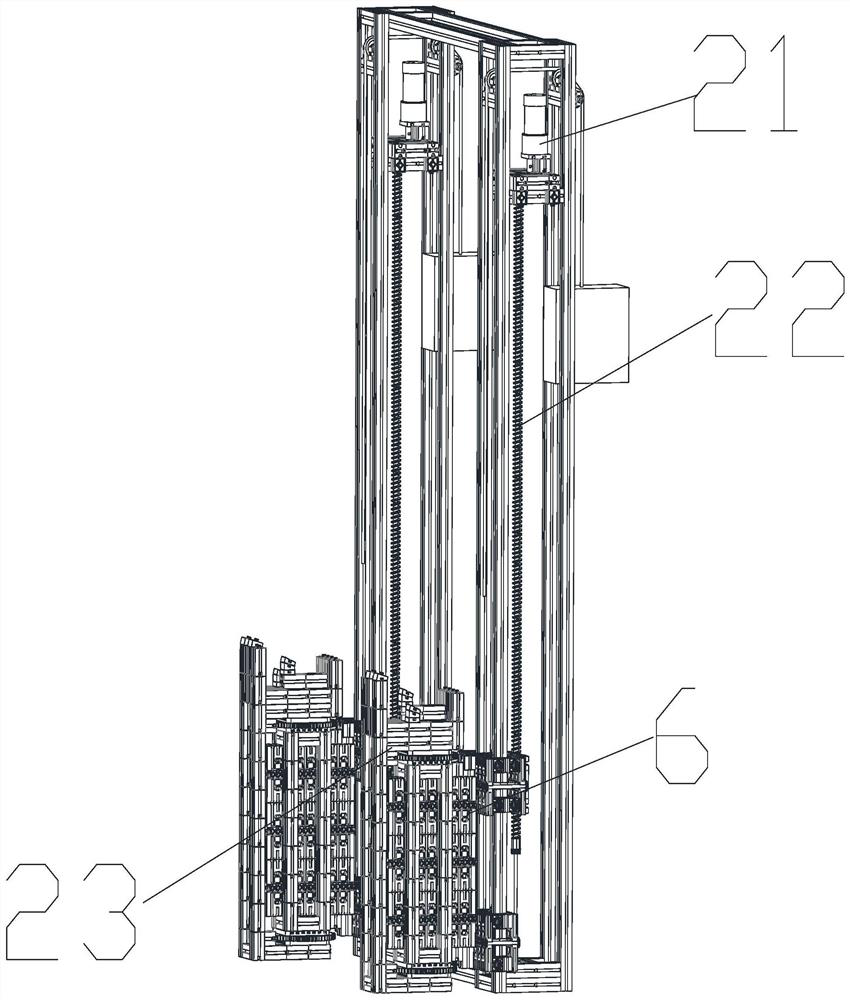

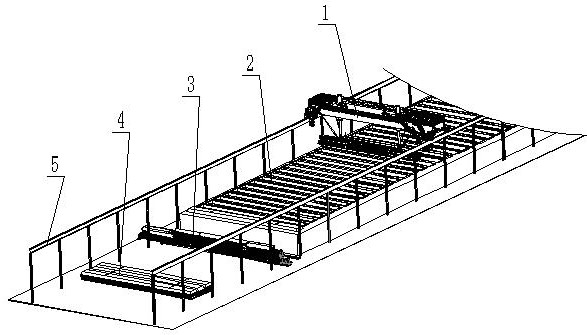

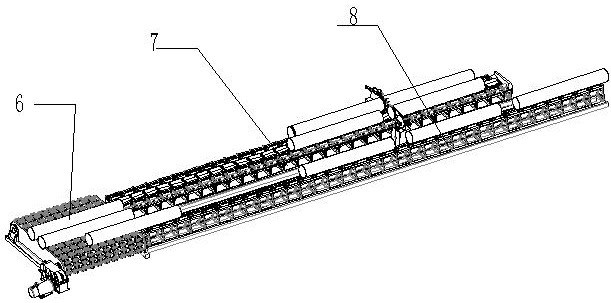

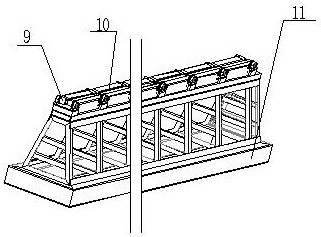

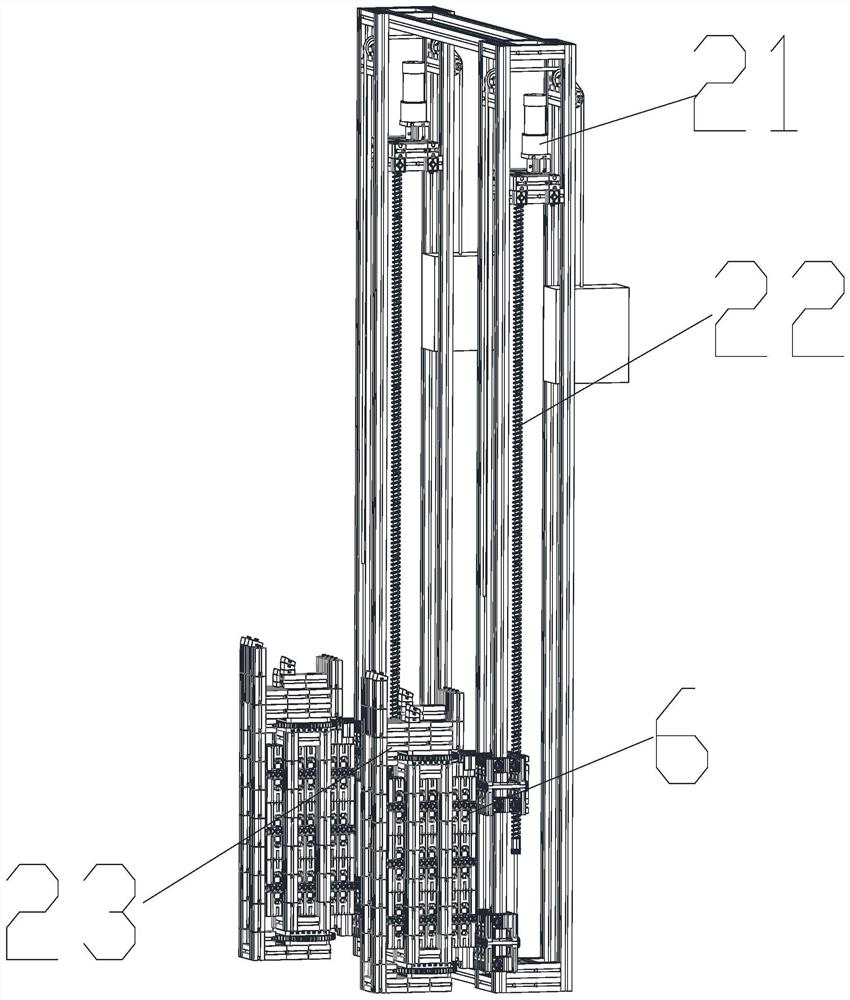

A carbon material roasting and graphitization production line hoisted by bridge lifting equipment

ActiveCN113758274BRealize the integrated processing and production processImprove processing productivityCharge manipulationTravelling cranesGraphite electrodeThermal insulation

Owner:HENAN WEIHUA HEAVY MACHINE +1

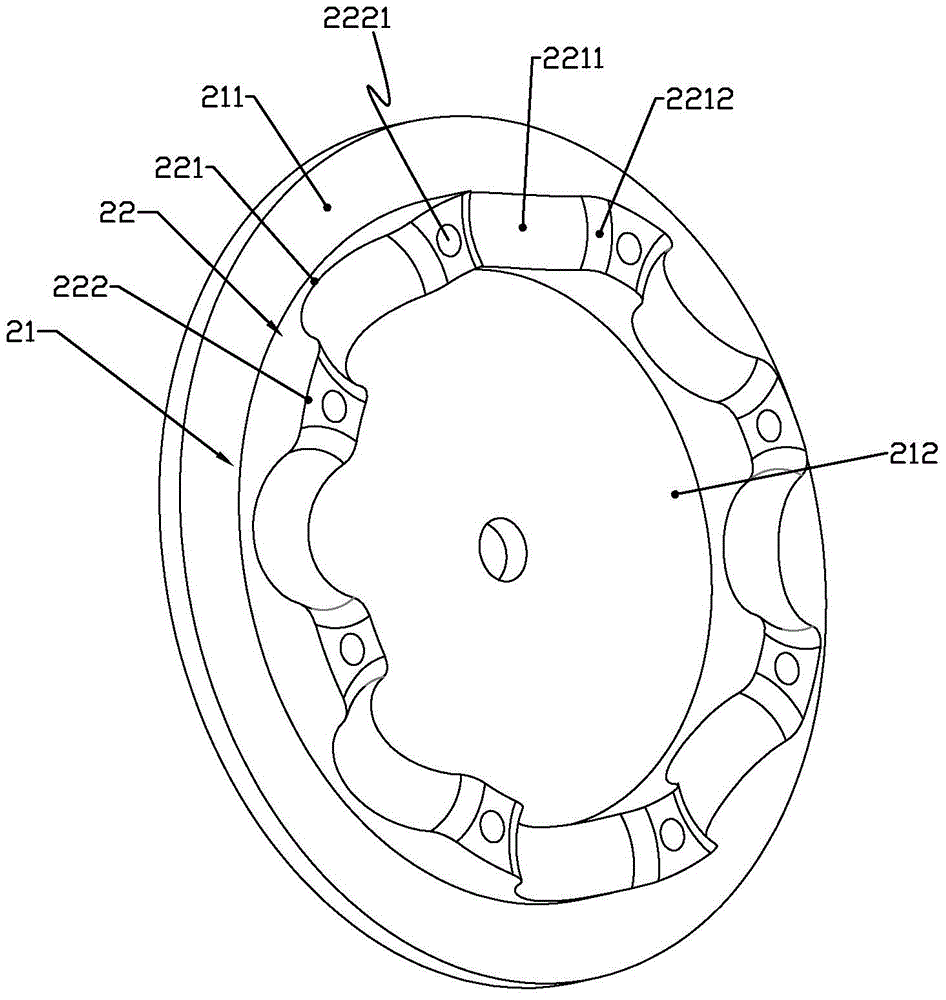

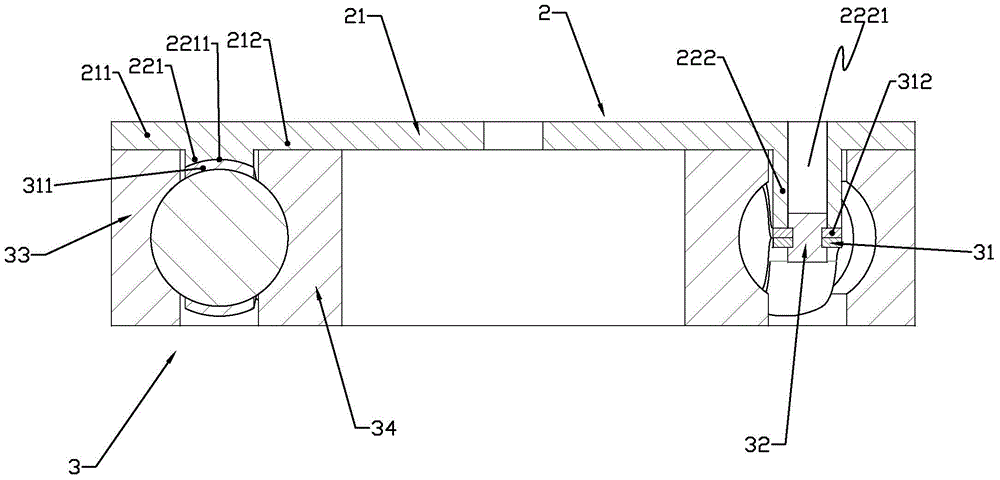

Wheel brake

InactiveCN101468655BImprove securityNo shakingCarriage/perambulator accessoriesHand cart accessoriesMechanical engineeringEngineering

Owner:NANSIN CO LTD

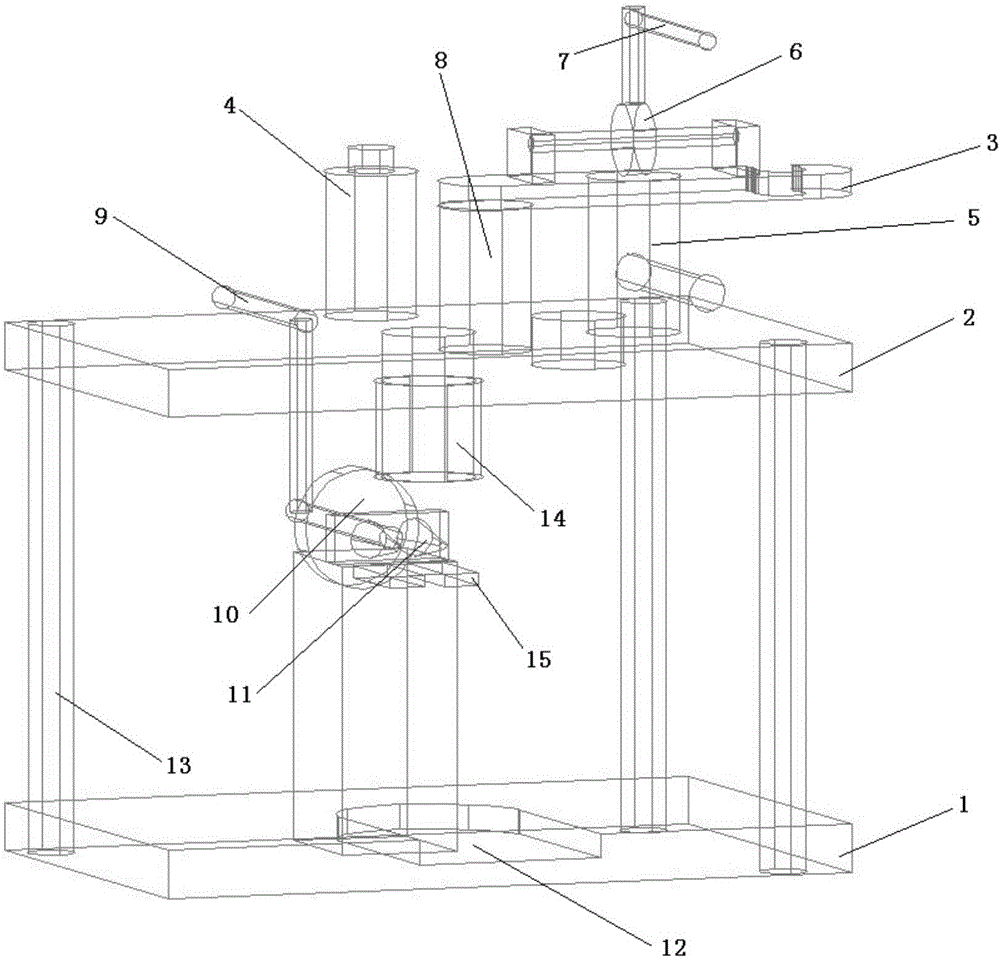

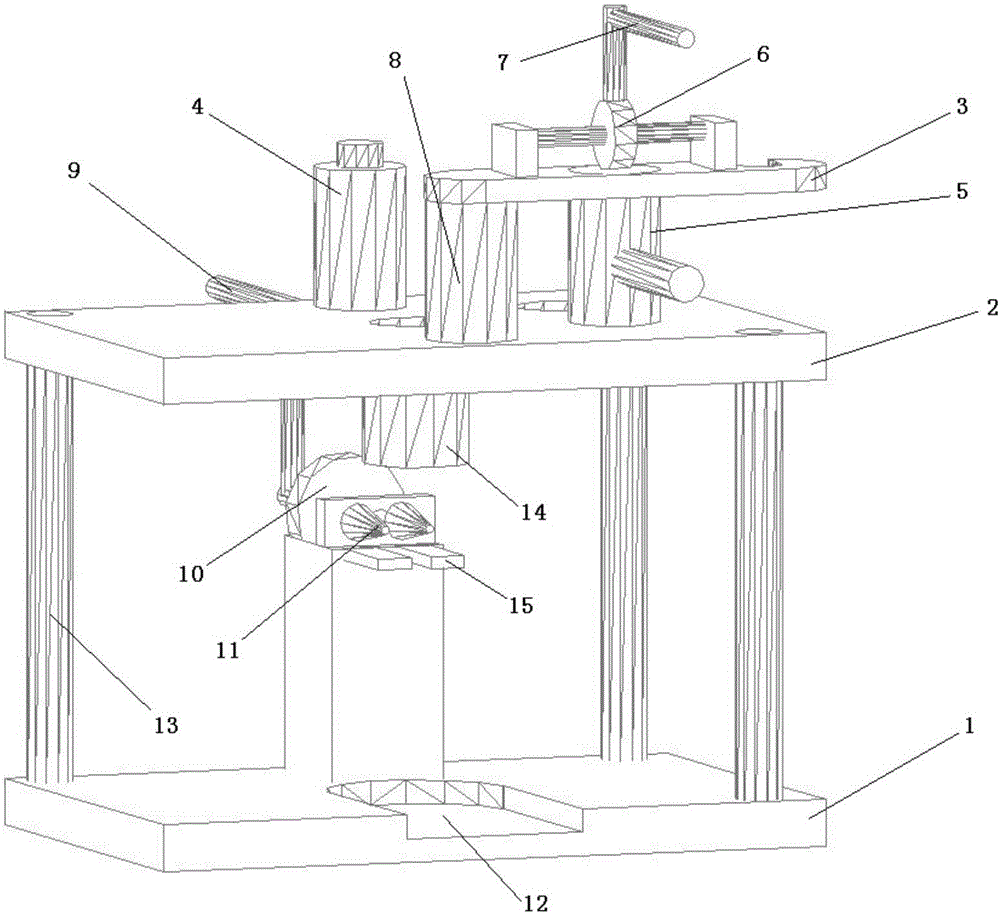

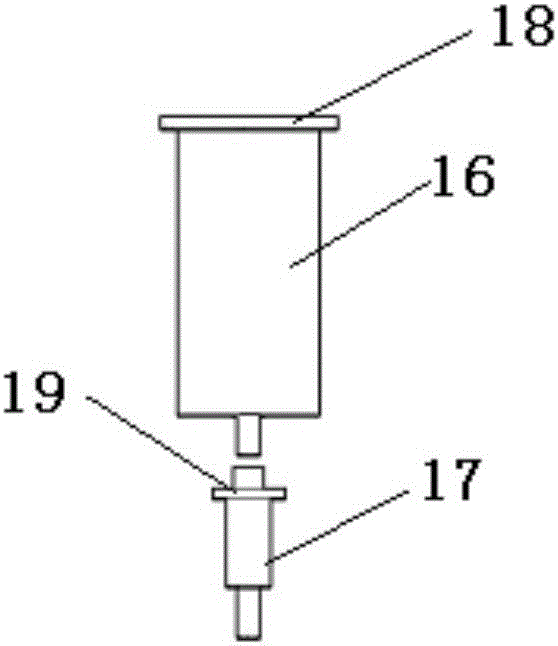

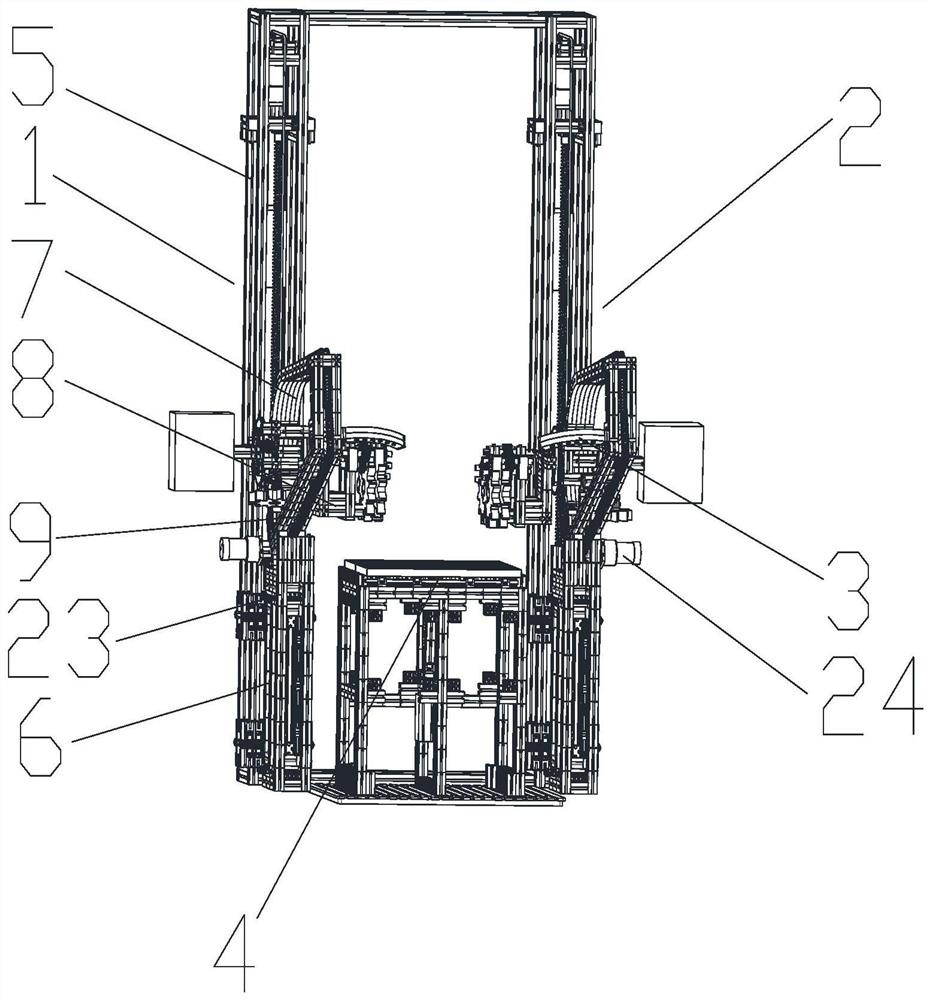

Extraction chromatography separation device applicable to manipulator operation in hot chamber

ActiveCN106486176ANot easy to damageEasy to operateComponent separationSolid sorbent liquid separationCompression deviceHigh intensity

The invention belongs to the technical field of extraction chromatography separation devices, and discloses an extraction chromatography separation device applicable to manipulator operation in a hot chamber. The device comprises a bottom plate, a top plate, a rotary cover plate, a limiting device, an eccentric wheel compression device, a liquid storage tube, a separation column, a column tube collimating device and an inserted separation device, wherein the top plate is positioned above the bottom plate, and a supporting upright post is arranged between the top plate and the bottom plate; and the rotary cover plate is positioned above the top plate, and two upright posts are arranged between the rotary cover plate and the top plate. The device has the beneficial effects of being convenient in manipulator operation in the hot chamber, tolerable to high-intensity radiation and capable of effectively preventing repairing.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Manifold

PendingCN110486487ASmall circumferential resistanceShort operating strokeSlide valveCircular discEngineering

The invention provides a manifold, and belongs to the technical field of valve equipment. The manifold solves the technical problems that an existing manifold is difficult to use, low in flow and thelike. The manifold comprises a valve body and a valve rod, wherein the valve body is provided with a penetrating through hole in the axial direction, the lower end of the valve rod is rotatably inserted into the through hole of the valve body, the upper end of the valve rod extends out of the upper end of the valve body upwards, a water outlet I is formed in the end face of the lower end of the valve body, a water outlet II and a water inlet are formed in the outer peripheral surface of the valve body correspondingly, a water inlet is formed between the water outlet I and the water outlet II,a plugging circular plate is arranged in the through hole and between the water inlet and the water outlet I, the outer peripheral surface of the plugging circular plate is in sealing connection withthe inner wall of the through hole, and the plugging circular plate is provided with a water passing hole I which penetrates vertically; and the lower end of the valve rod is connected with a rotary plate and can drive the rotary plate to rotate, and the side part of the lower end of the valve rod is provided with a plugging part capable of plugging or opening the water outlet II during rotation.The manifold has the advantages that the flow is large and the labor is saved.

Owner:ZHEJIANG SUERDA SANITARY

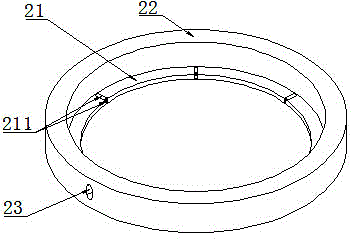

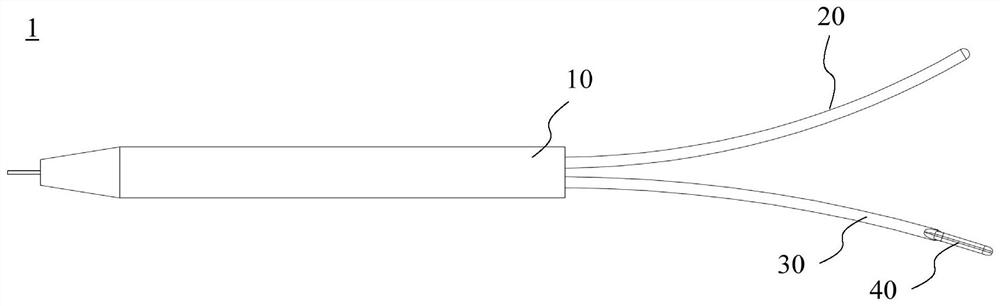

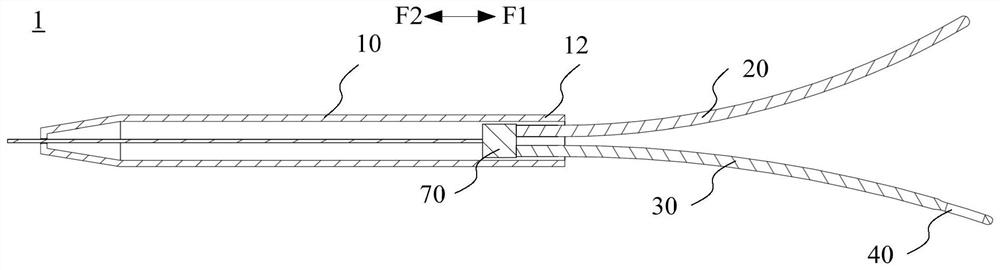

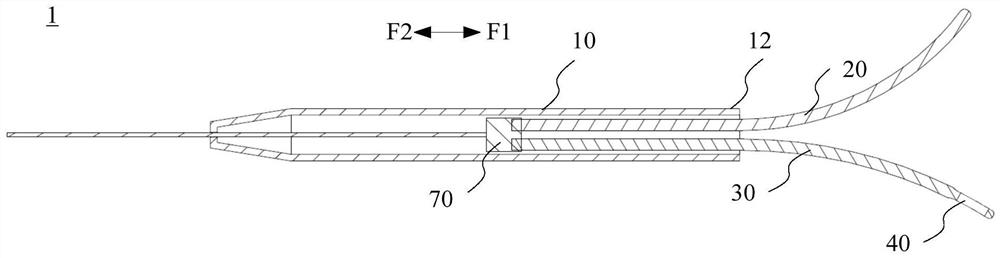

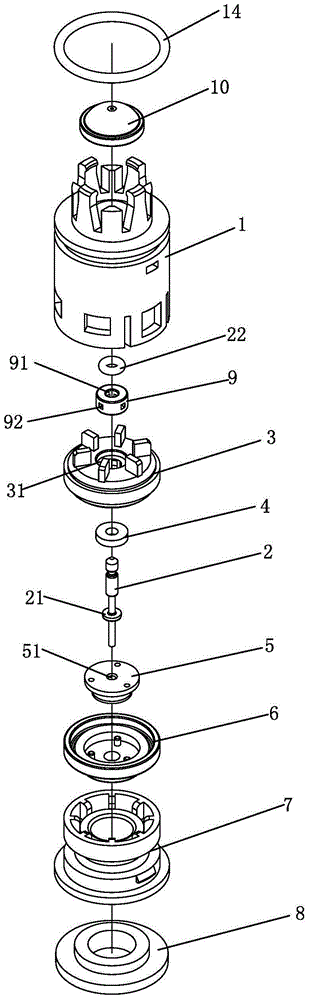

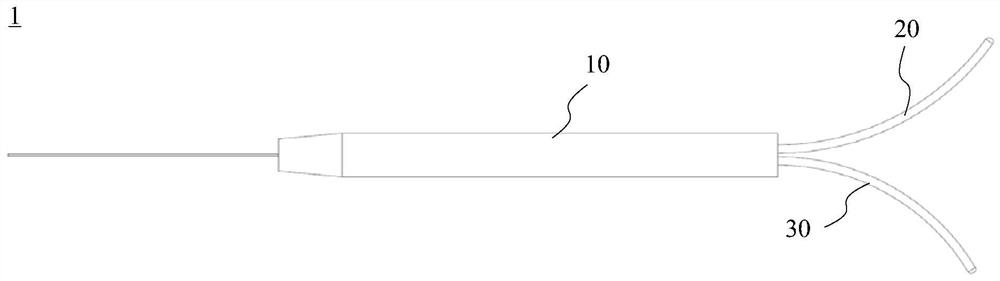

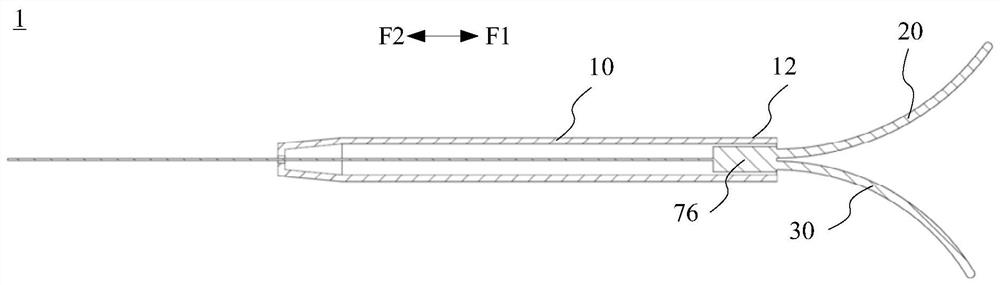

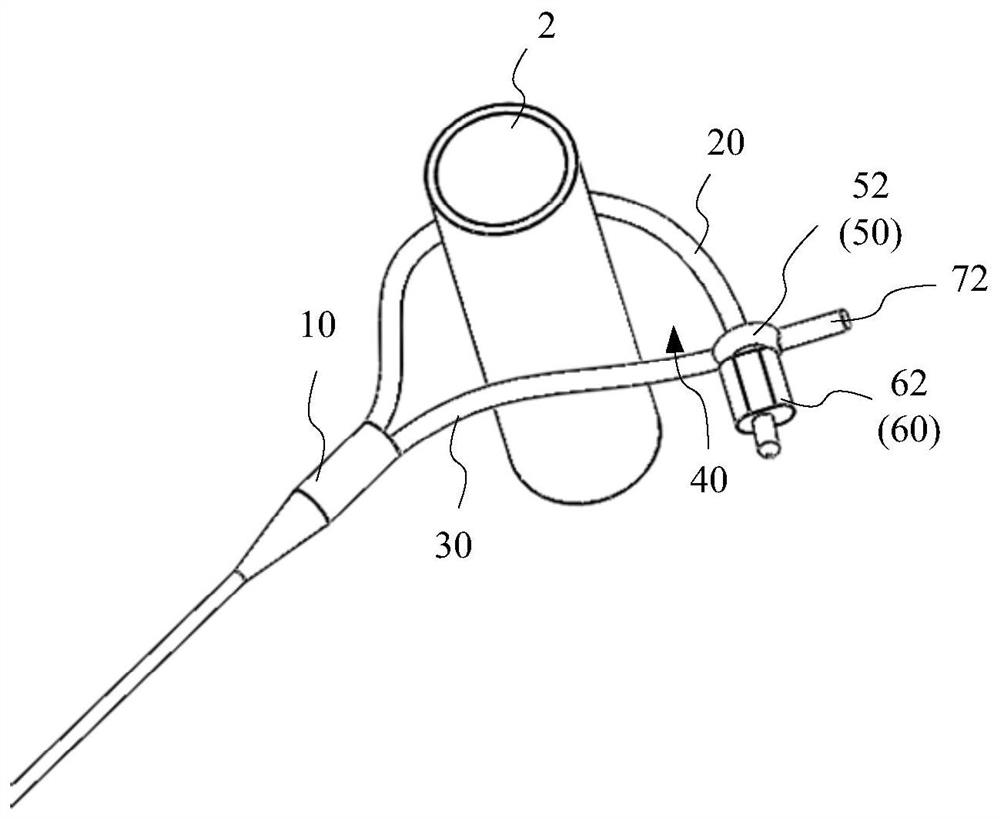

Cavity tube adjusting instrument

The invention provides a cavity tube adjusting instrument which mainly comprises a body, a first surrounding piece and a second surrounding piece, wherein the first surrounding piece and the second surrounding piece are movably connected with the body. Wherein at least one of the first surrounding piece and the second surrounding piece is provided with a locking structure, the locking structure can enable the first surrounding piece and the second surrounding piece to be combined with each other so as to form a surrounding part surrounding a target lumen in the circumferential direction, and the first surrounding piece and the second surrounding piece can synchronously reciprocate relative to the body so as to adjust the sectional area of the surrounding part. And the cross section of the target cavity tube is deformed to different degrees according to different sectional areas of the surrounding part. Therefore, the flow rate of the liquid in the target cavity tube can be conveniently and accurately regulated and controlled, and the flow rate regulating device has the advantage of being short in operation stroke.

Owner:THE NAVAL MEDICAL UNIV OF PLA +1

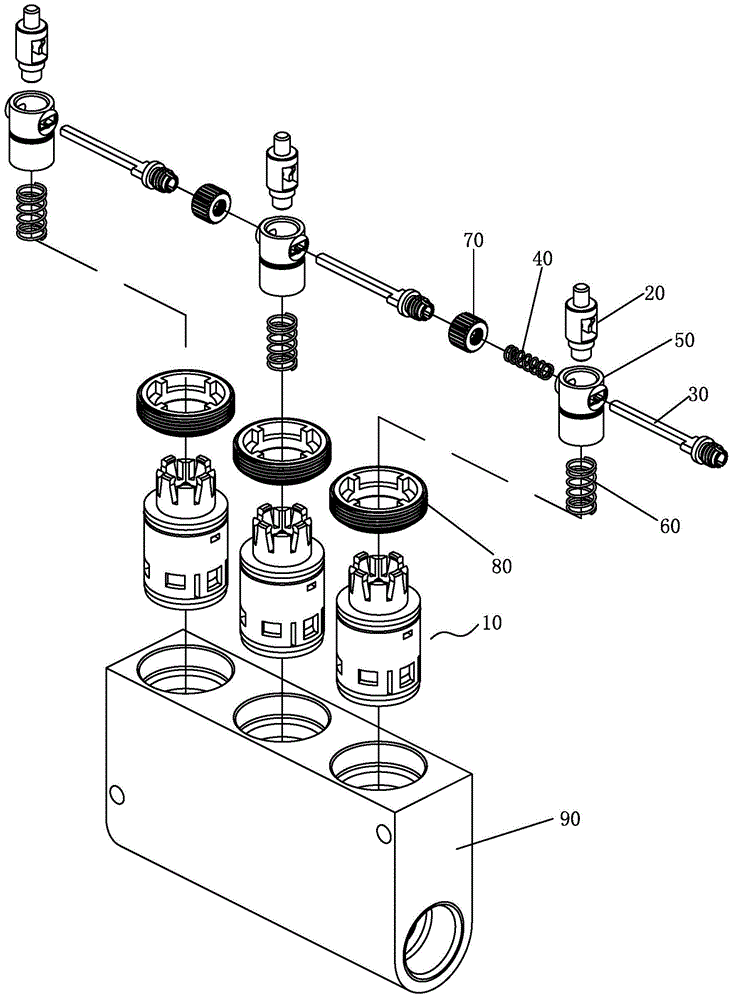

A valve core group switching control mechanism

ActiveCN103851227BNew control methodSimple controlOperating means/releasing devices for valvesMultiple way valvesKey pressingComputer module

The invention discloses a valve element group switching control mechanism. The valve element group switching control mechanism comprises at least two valve elements and further comprises at least two key modules and a first elastic piece. Each key module comprises a key for opening the corresponding valve element and a control rod, wherein the keys and the valve elements are correspondingly matched; each control rod can be assembled on the corresponding key in a way of being capable of moving along the axial direction of the corresponding key; a locking structure for locking the corresponding key is matched between each control rod and the corresponding key. The control rods of at least two key modules are coaxially linked; the control rod of at least one key module is connected with the first elastic piece for resetting; any one key at a resetting state is used for opening the corresponding valve element in a pressing manner and drives each control rod to do the axial movement; the corresponding control rod is used for driving the corresponding locking structure through resetting to lock the pressed key; the residual control rod is used for driving the corresponding locking structure through axial movement to unlock the corresponding pressed key, so that the key is reset. With the adoption of the structure, the valve element group switching control mechanism can be used for realizing linkage type switching control of at least two valve elements.

Owner:JOMOO KITCHEN & BATHROOM

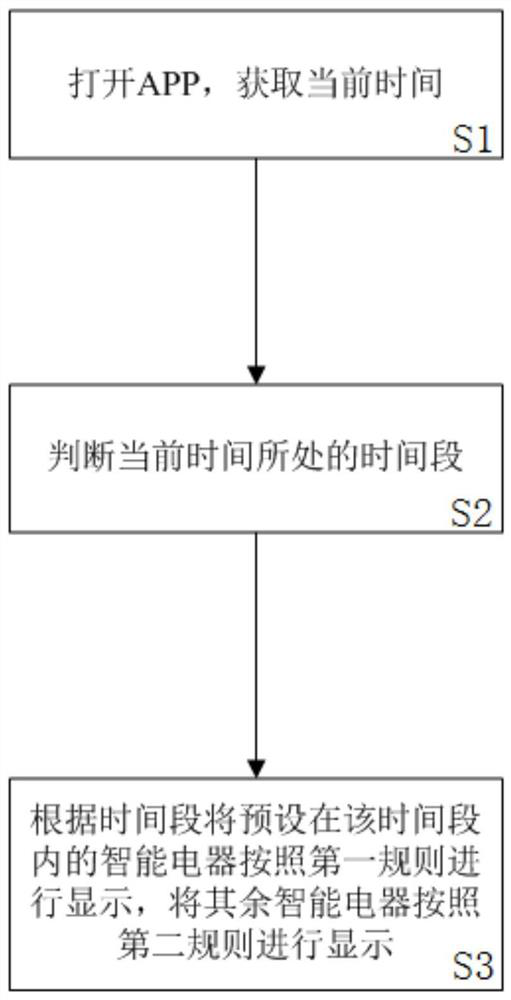

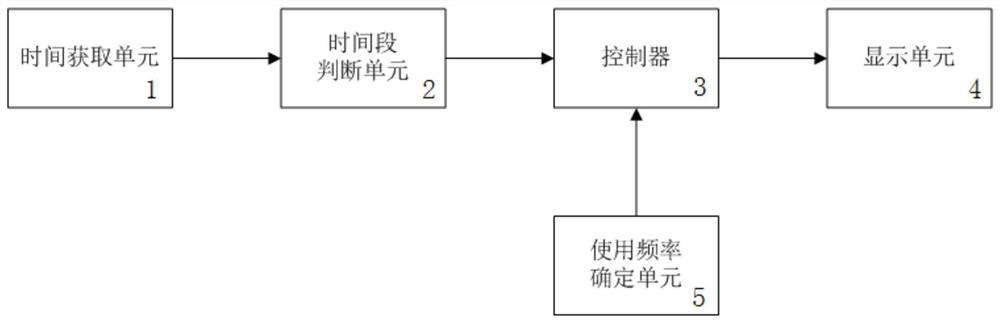

APP display method and device and mobile terminal applying same

PendingCN112198806AShort operating strokeImprove experienceComputer controlProgramme total factory controlComputer hardwareReal-time computing

The invention discloses an APP display method and device and a mobile terminal applying the APP display method and device, and the APP display method specifically comprises the steps: S1, starting anAPP, and obtaining the current time; S2, judging a time period in which the current time is located; and S3, according to the time period, displaying the intelligent electric appliances preset in thetime period according to a first rule, and displaying the rest intelligent electric appliances according to a second rule, wherein the rest intelligent electric appliances are intelligent electric appliances which are not preset in the time period. The method is divided according to different time periods of each day, electric appliance icons possibly needed in the current time period are displayed at the front positions in the different time periods, the other electric appliance icons are displayed at the rear positions, a consumer can quickly find an electric appliance needing to be operated, the operation stroke of the consumer is reduced, and the operation experience feeling is improved.

Owner:VATTI CORP LTD

Not-opening door operation tapping unit of low voltage distribution cabinet

InactiveCN101051734BTo achieve the purpose of not opening the doorHigh strengthSwitchgear with horizontal withdrawalElectricityLow voltage

Owner:周金隆 +1

Deep groove ball bearing cage removal method

Owner:C&U CO LTD

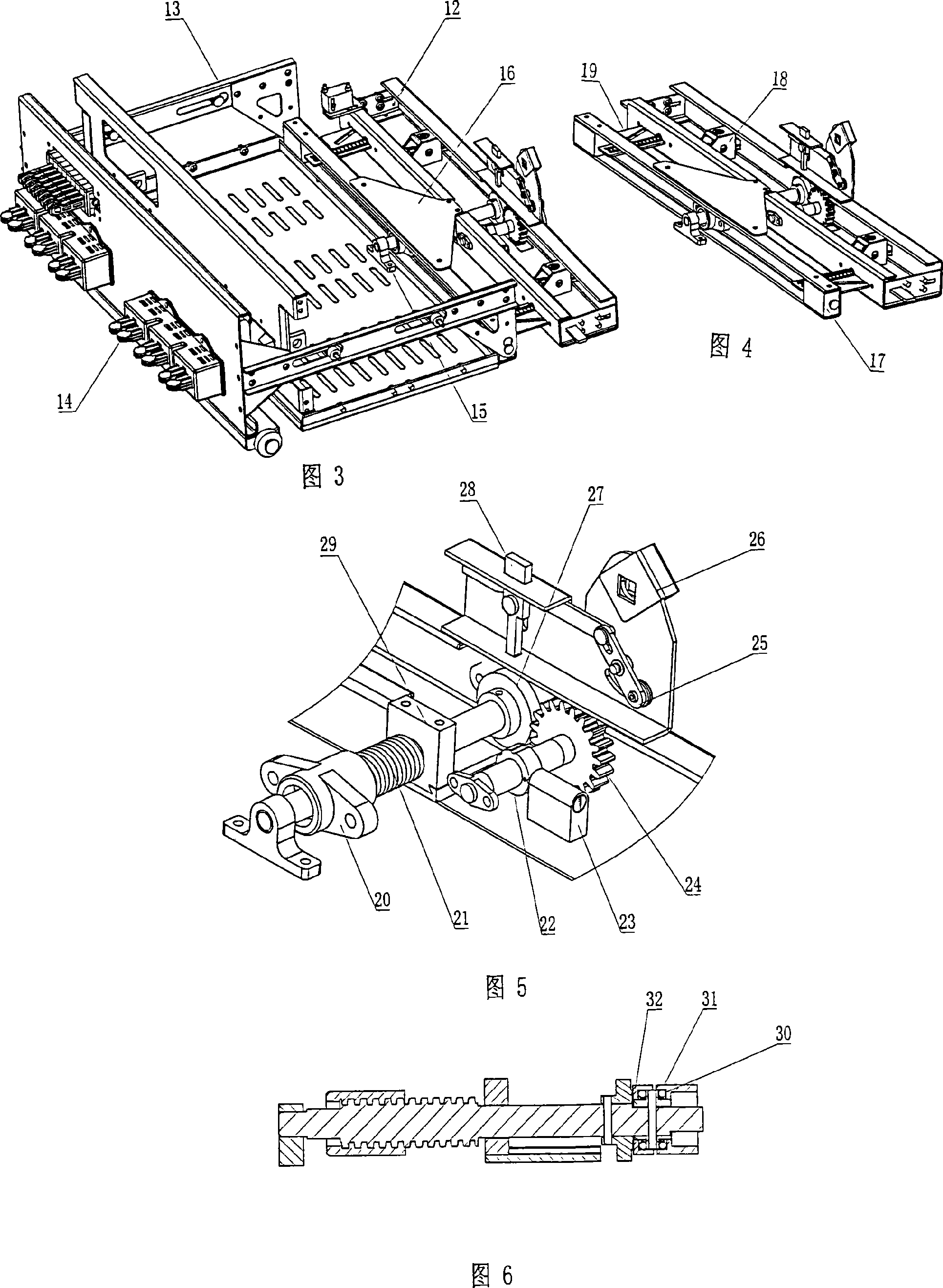

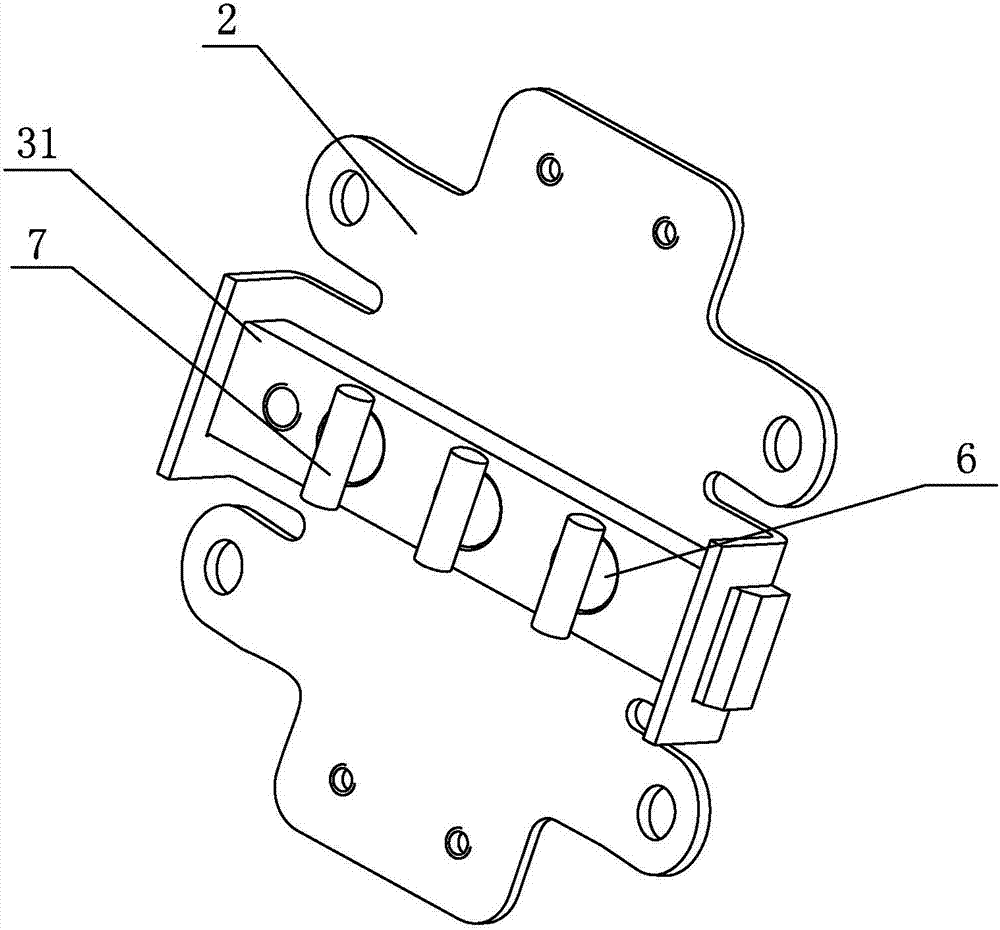

Direction switch assembly of a forklift

The invention discloses a direction switch assembly of a forklift. The direction switch assembly comprises two direction switches, a fixing plate, a gear shift mechanism and a prodding element, wherein the gear shift mechanism consists of a guide rail which is horizontally arranged at the intermediate position of the fixing plate and a sliding block matched with the guide rail, and protrusions are respectively arranged at the intermediate position of the upper side end surface and the intermediate position of the lower side end surface of the sliding block; the two direction switches are respectively fixed on the fixing plate, and are oppositely and symmetrically distributed on the upper side and the lower side of the sliding block, and when free ends of control rods of the direction switches are in contact with the end faces of the protrusions, the direction switches are closed; the prodding element is connected to the front surface of the sliding block. The direction switch assembly disclosed by the invention has the advantages that the direction switch assembly adopts a tiled structure, the switching off or the switching on of the two direction switches is controlled through different positions of the sliding block on the guide rail, and besides, the prodding element is directly connected to the sliding block, so that the structure is more compact; therefore, the mounting position of the direction switch assembly can be changed and is no longer limited to steering tube columns of the forklift, and besides, the prodding operation mode of the prodding element conforms to human engineering.

Owner:宁波海迈克动力科技有限公司

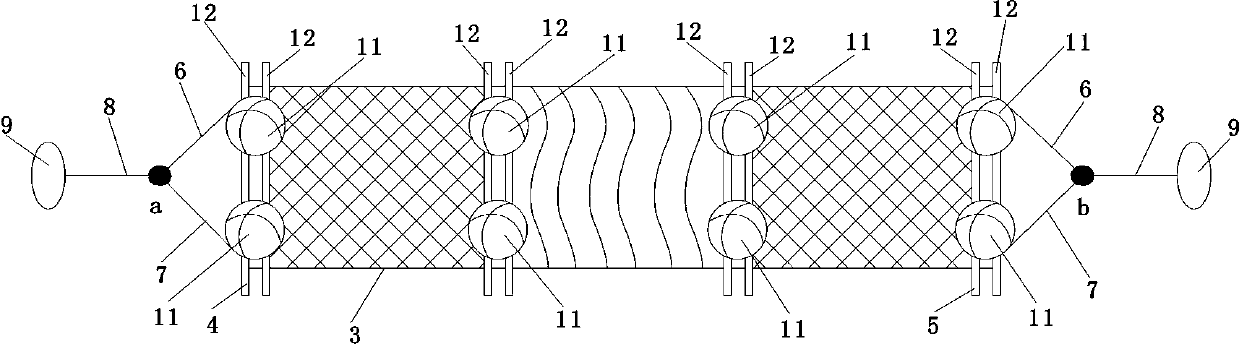

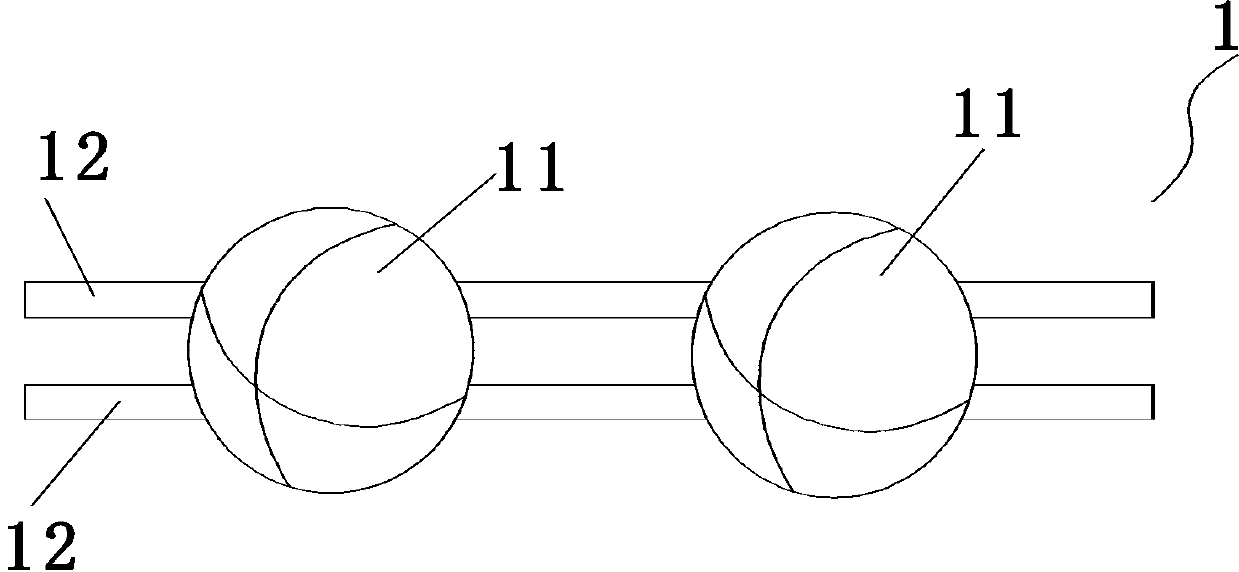

Laver breeding device

InactiveCN110800602AEasy to operateSimple structureCultivating equipmentsSeaweed cultivationAnimal scienceEngineering

Owner:汕头市佳盛食品科技有限公司

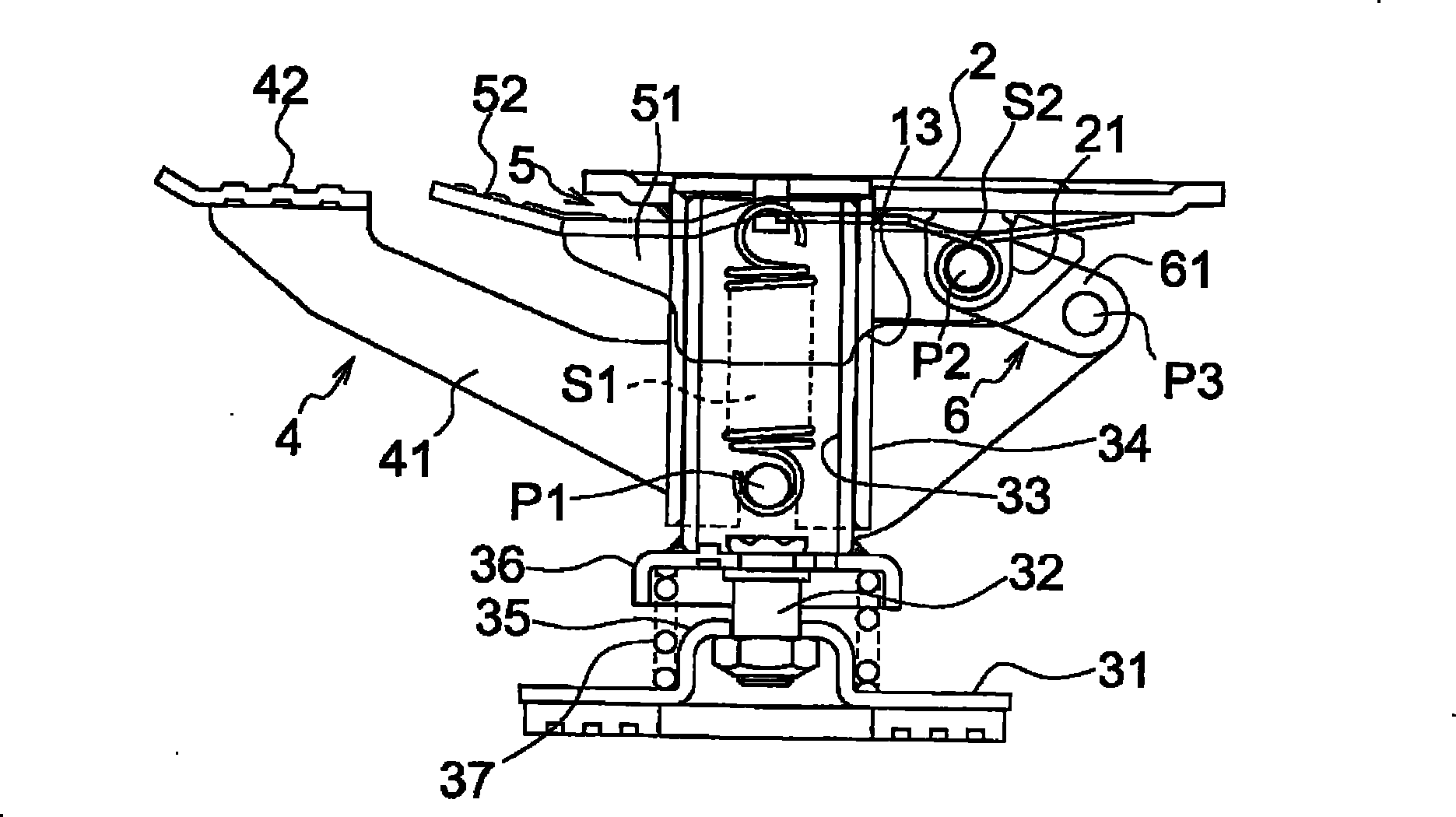

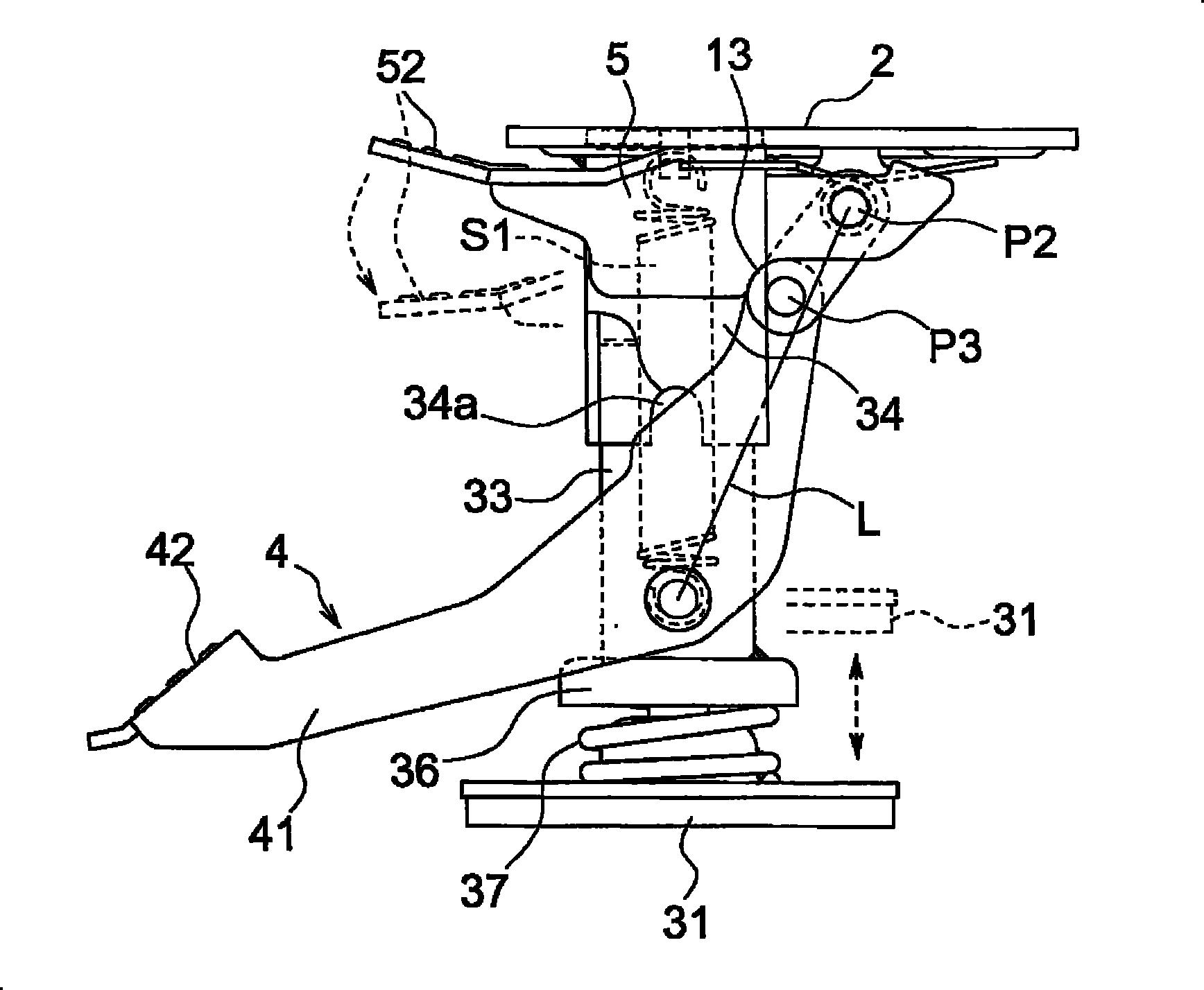

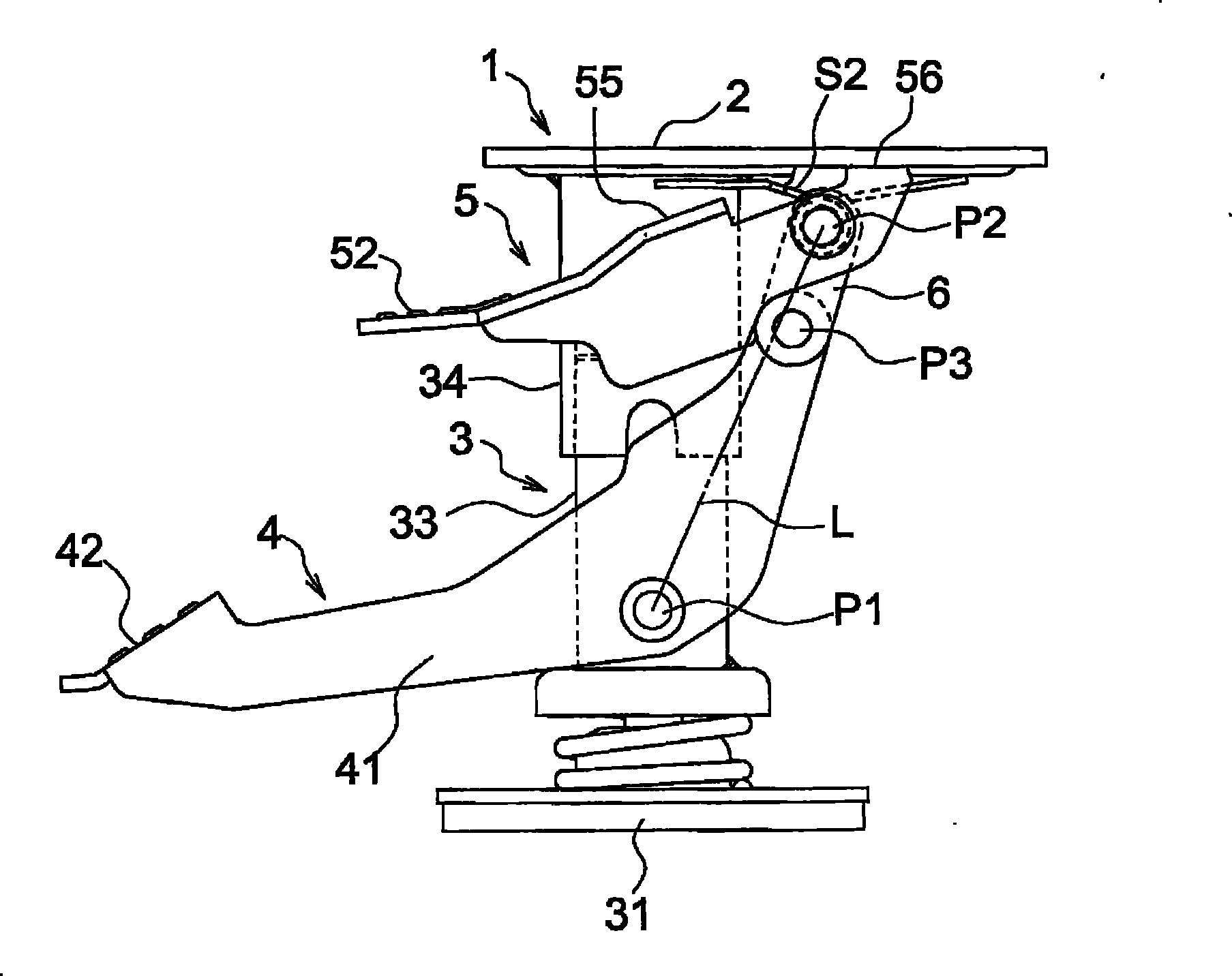

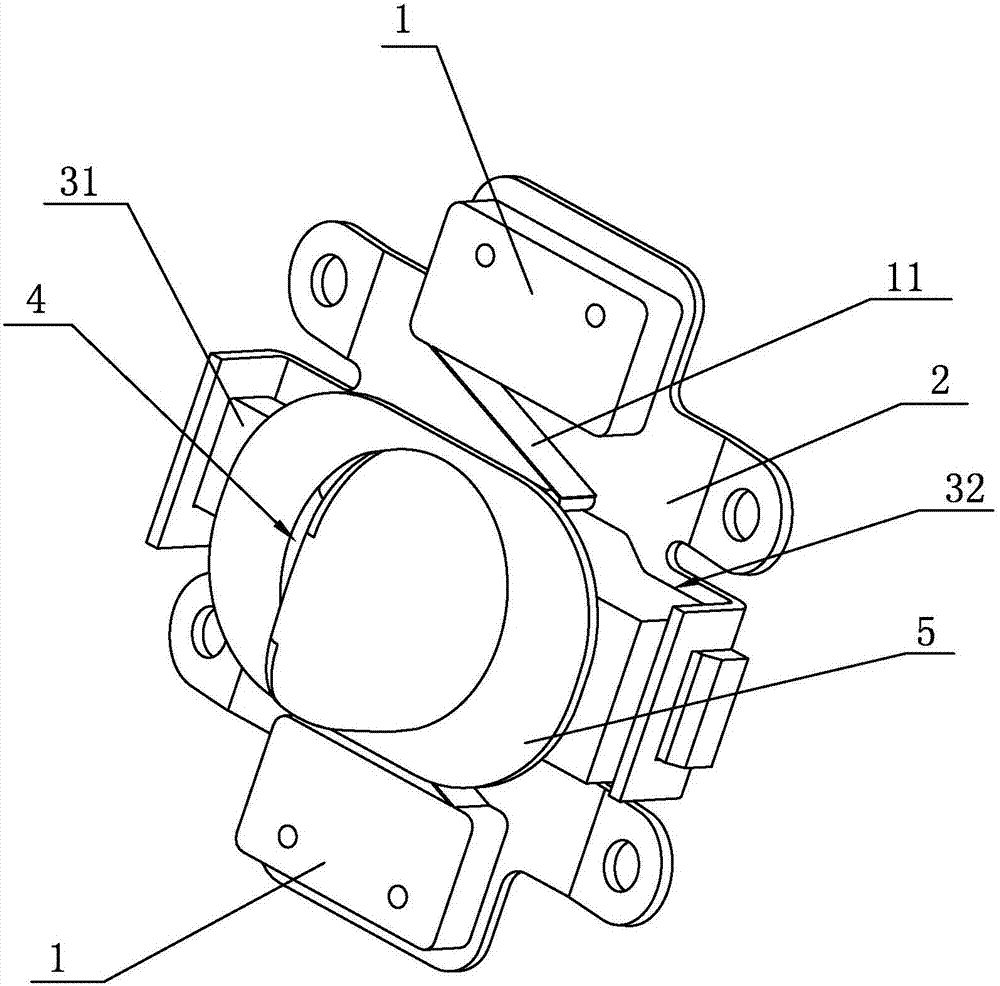

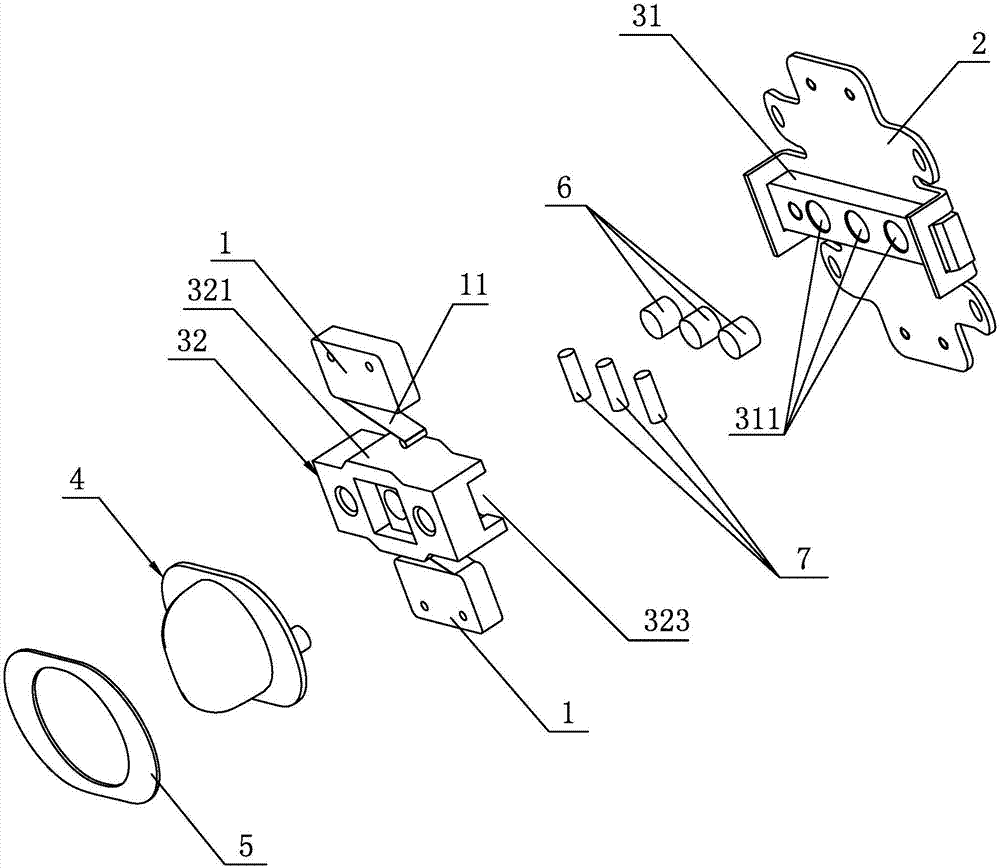

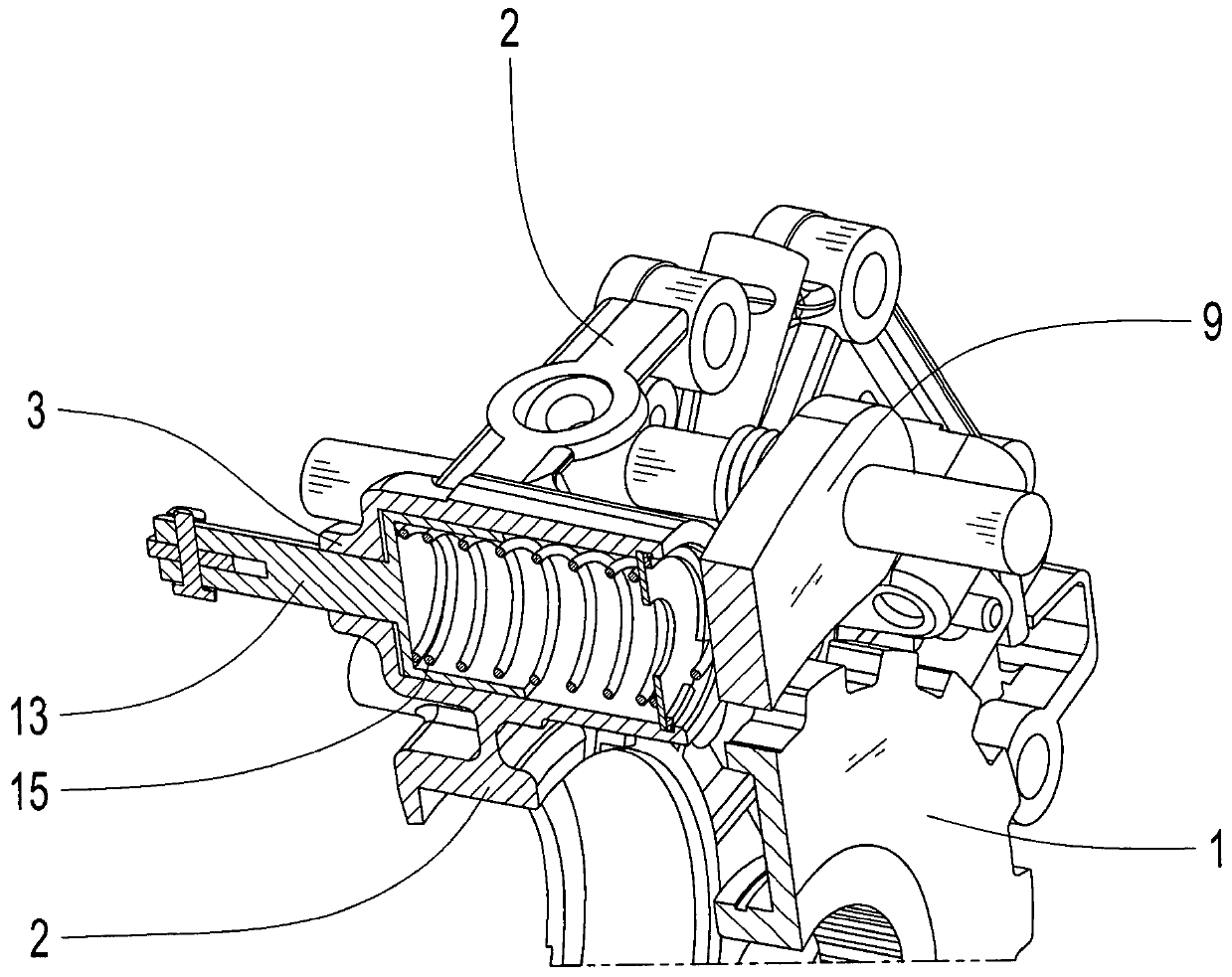

Arrangement of a Parking Lock in a Vehicular Transmission

ActiveCN110748641ASimple structureSave installation spaceBraking element arrangementsGearing controlControl theoryMechanical engineering

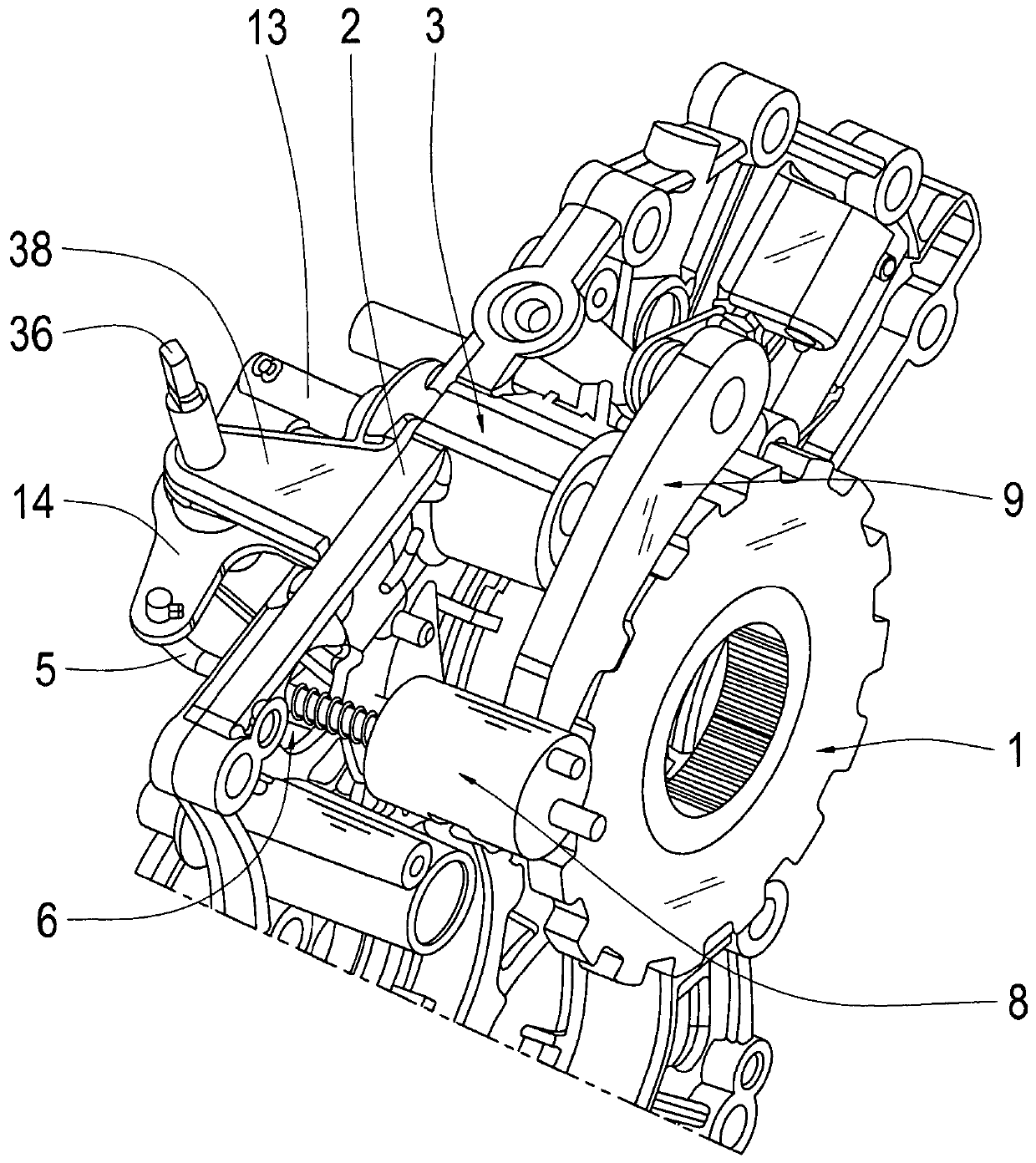

The invention relates to an arrangement of a parking lock in a vehicular transmission. A parking lock in a vehicle transmission includes a locking mechanism for locking and releasing a parking interlock gear (1) and an actuating unit. The actuating unit is coupled via a coupling mechanism to the locking mechanism in order to actuate the locking mechanism between an interlock position and a releaseposition of the parking interlock gear (1). The parking lock is arranged on an intermediate plate (2) in a housing of the vehicle transmission.

Owner:ZF FRIEDRICHSHAFEN AG

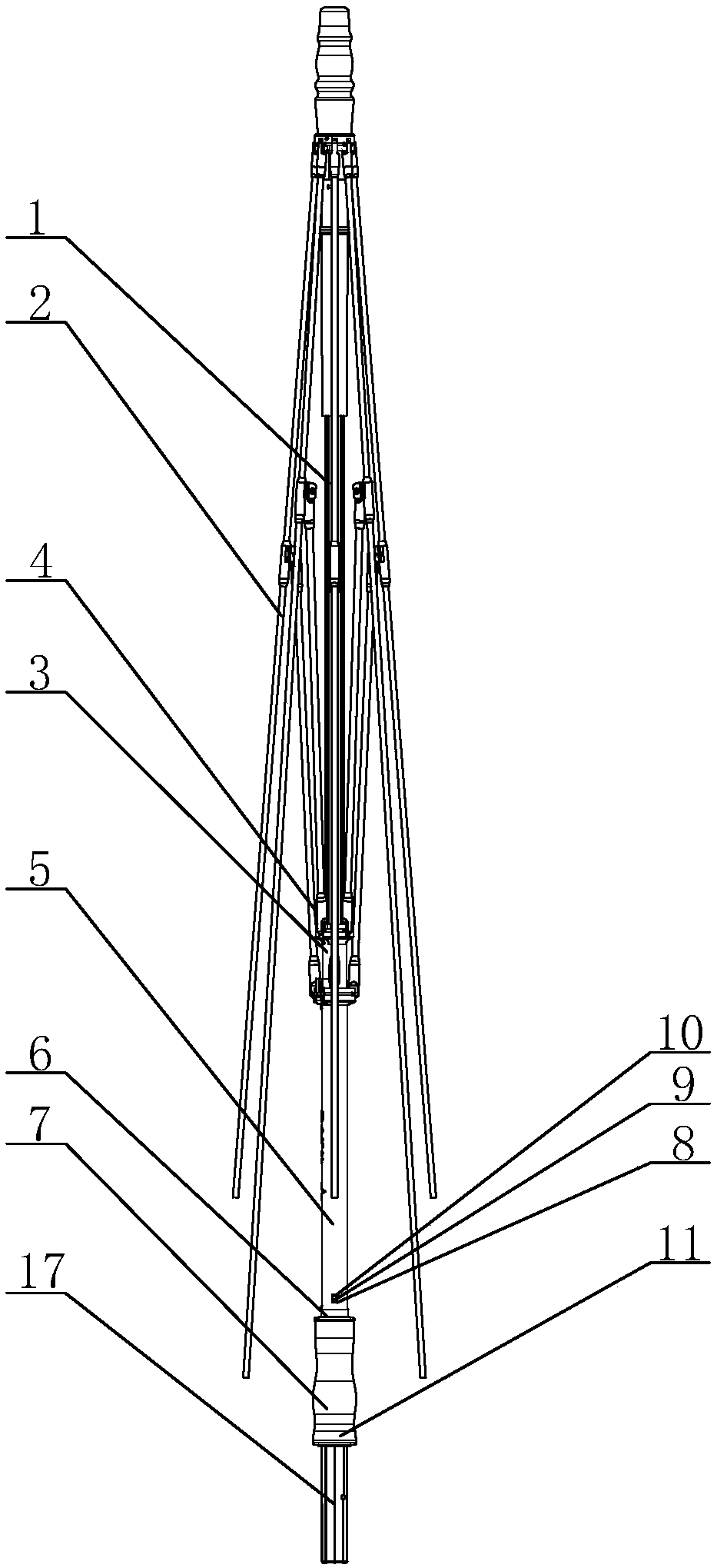

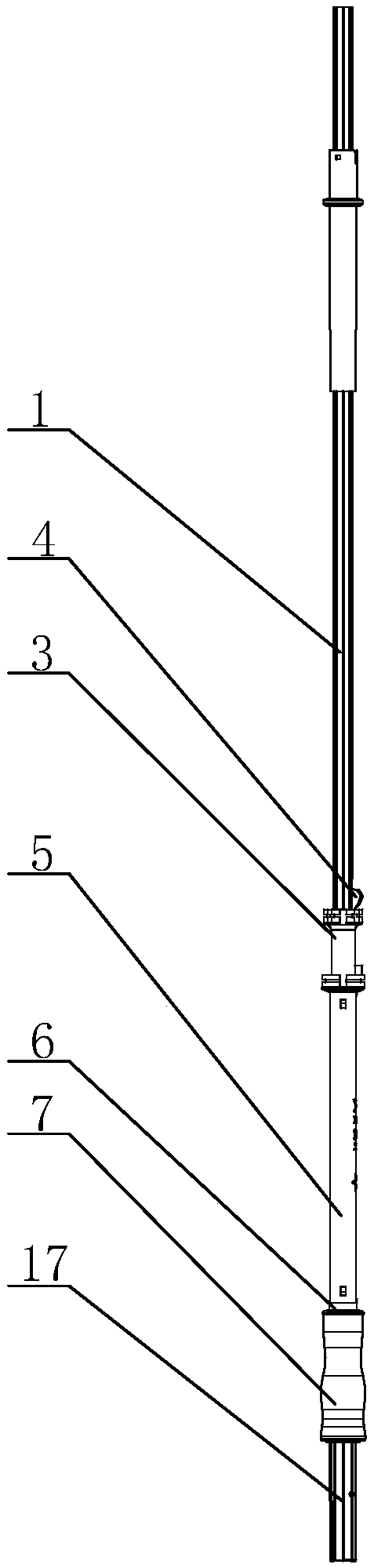

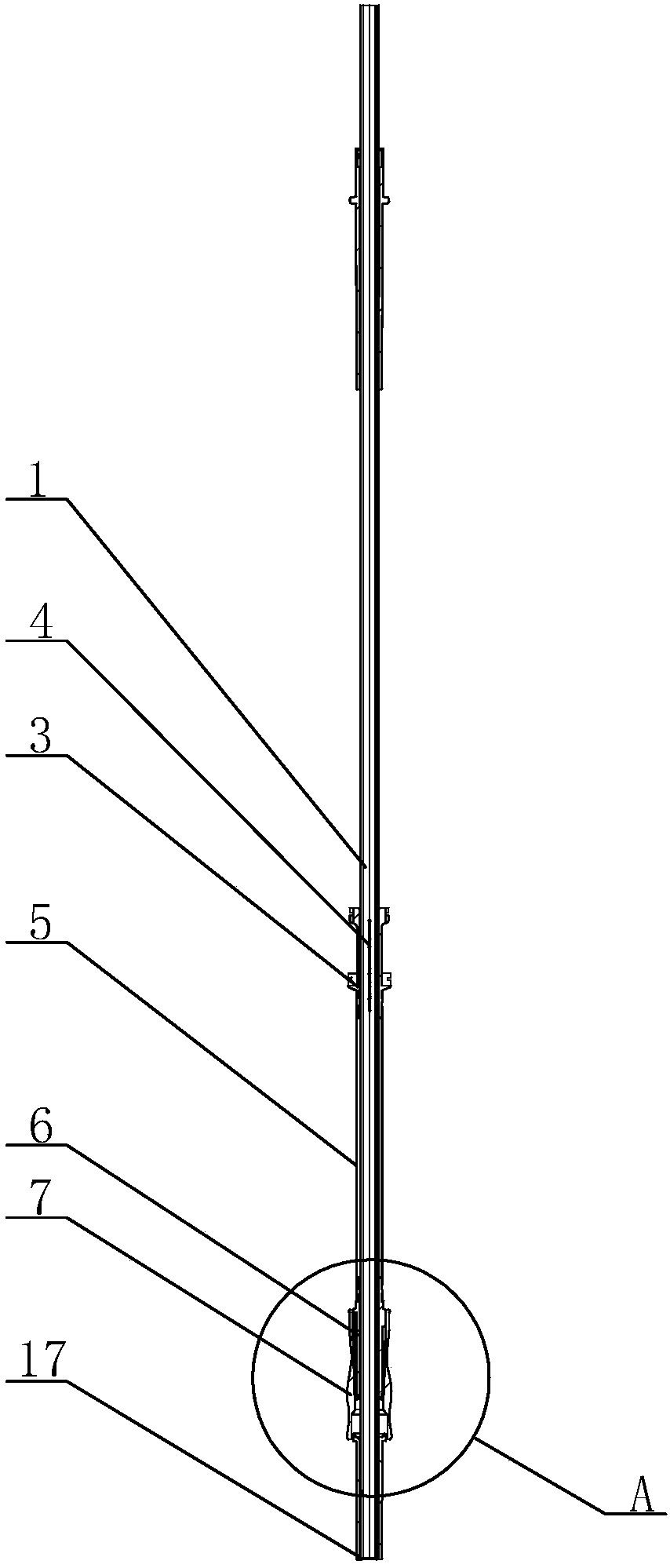

Quick and labor-saving unfolding and folding device of umbrella

The invention discloses a quick and labor-saving unfolding and folding device of an umbrella. The quick and labor-saving unfolding and folding device of the umbrella comprises a middle rod. The middlerod is sleeved with a lower nest connected with umbrella ribs. An elastic arch piece is installed in the middle of the middle rod. The lower end of the lower nest is fixedly connected with a lengthened pushing rod. An unfolding and folding structure is installed at the lower part of the lengthened pushing rod and comprises a limiting barrel and a pushing disc, the limiting barrel is fixed to thelower end of the lengthened pushing rod, the pushing disc is arranged on the limiting barrel in a sleeving mode and is in sliding fit with the limiting barrel, and the lower end of the pushing disc isconnected with an arch piece barrel. According to the quick and labor-saving unfolding and folding device of the umbrella, the operation length of the arms of a user is reduced by means of the lengthened pushing rod and the unfolding and folding structure, more labor is saved during use, and convenience is brought during use.

Owner:ZHEJIANG TIANHE RAIN GEAR DESIGN

Drain valve manual integrated button

Owner:XIAMEN JIAPULE ELECTRONICS TECH

An auxiliary rack for putting on and taking off a pullover

ActiveCN112056903BResolve the difficulty of movementLower operating heightApparel holdersElectric machineryEngineering

The present invention is an auxiliary frame for putting on and taking off a pullover, which comprises a symmetrically arranged first auxiliary frame and a second auxiliary frame. The first auxiliary frame includes a fixed bracket. There is an arc-shaped front pull guide rail on the seat, and a manipulator is installed sliding on the front pull guide rail, and a transmission chain for driving the manipulator to slide is also provided on the front pull guide rail. The rotating arm on the seat, the finger clamp mechanism fixed on the rotating arm and the rotating arm motor fixed on the sliding seat, the rotating arm motor is used to drive the rotating arm to rotate, and the finger clamp mechanism includes a pressing bracket and a clothes folding bracket set oppositely , the pressing bracket is rotated with a pressing plate, the pressing plate is rotated with a roller one, and the clothes-folding bracket is rotated with a roller two that cooperates with the roller one to compress the pullover. Clothes machine, the structure of the second auxiliary frame is the same as that of the first auxiliary frame.

Owner:CHANGZHOU INST OF TECH

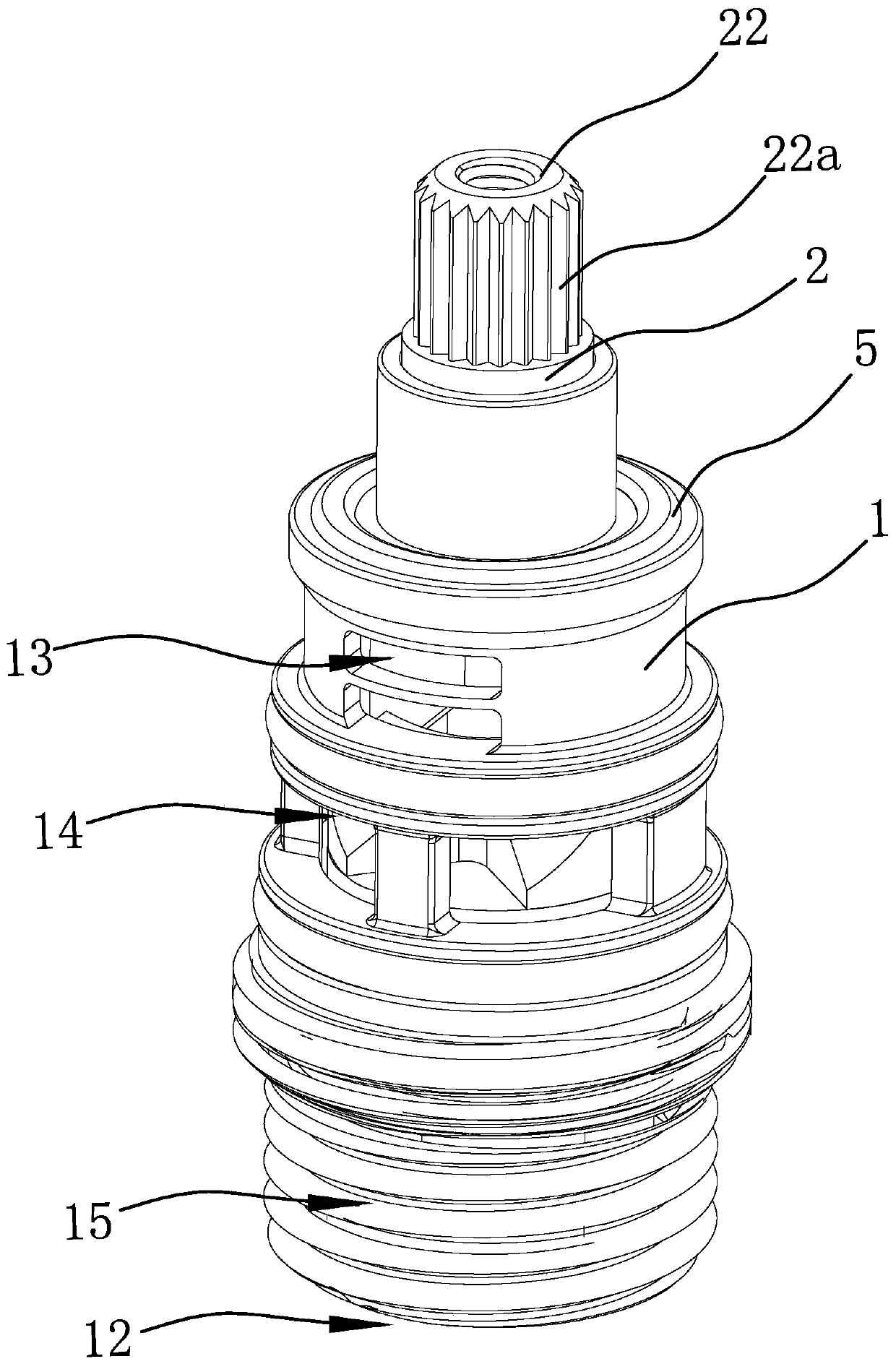

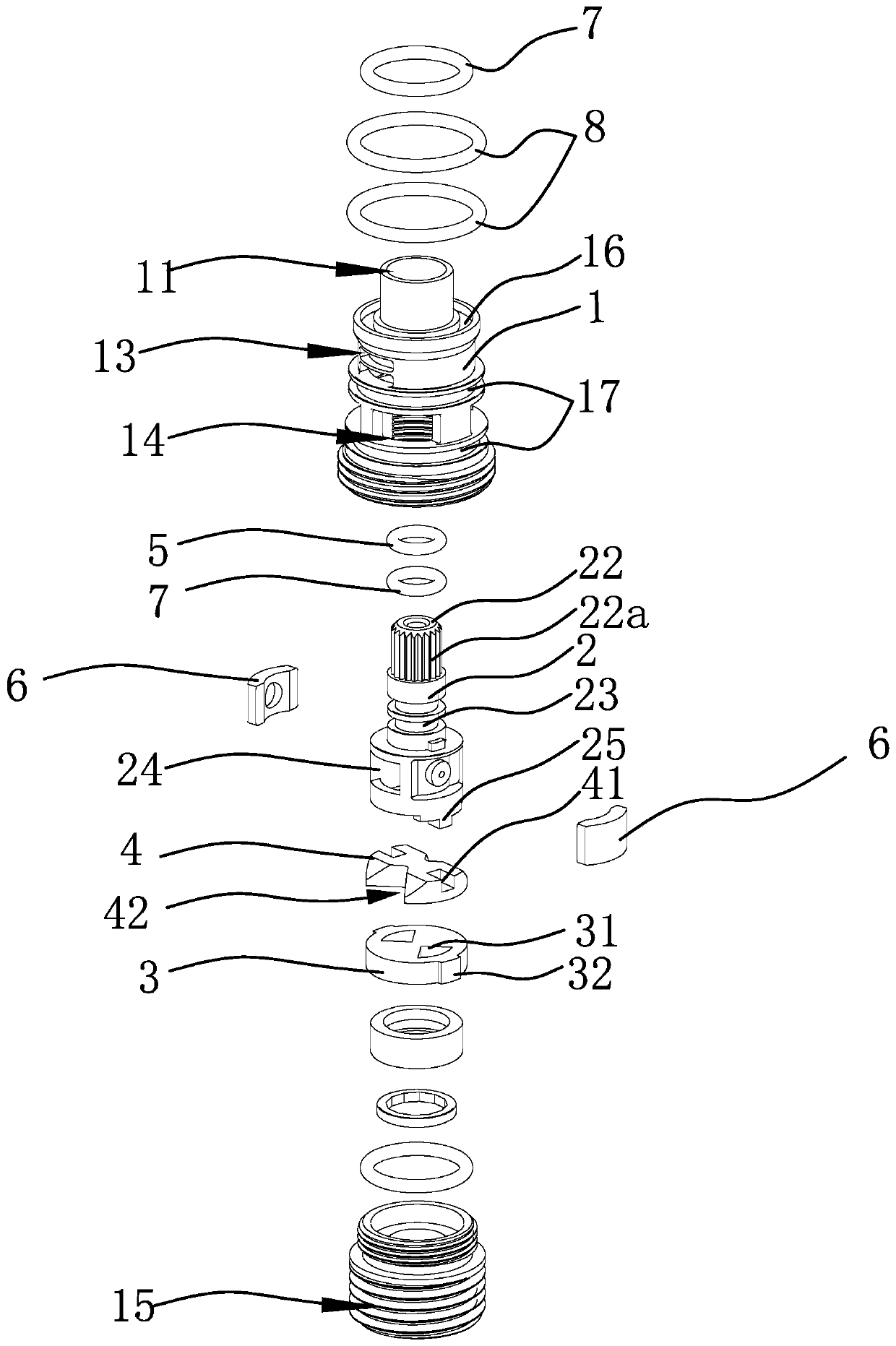

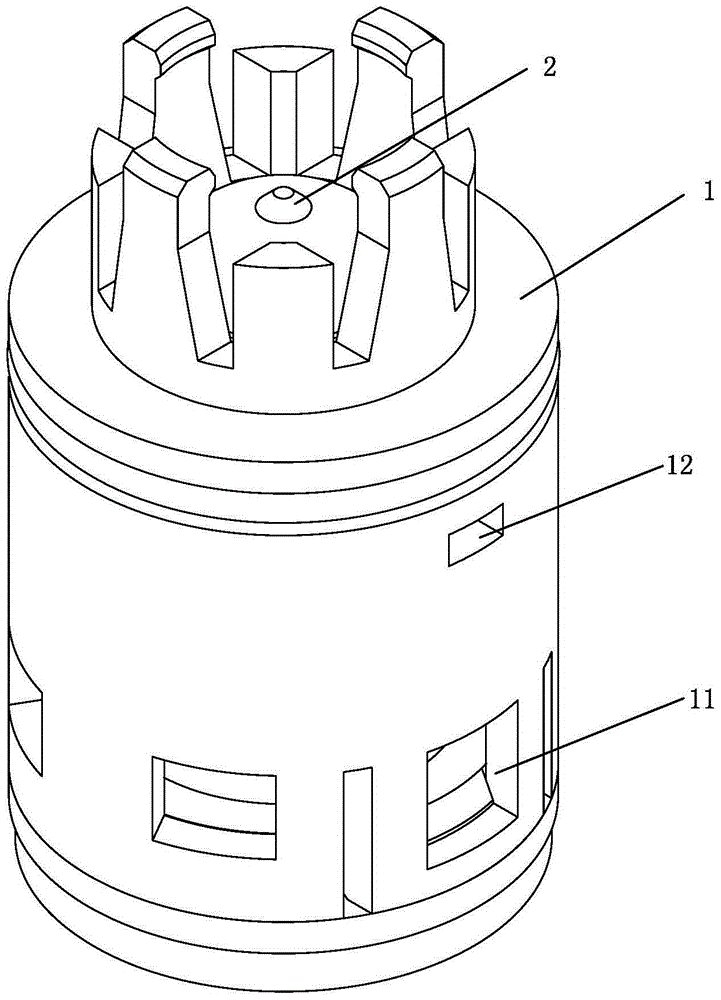

A spool and waterway control valve

ActiveCN103742675BEasy to useReduce water pressureOperating means/releasing devices for valvesMultiple way valvesEngineeringControl valves

The invention discloses a valve element and a water way control valve. The valve element comprises a valve shell, a control rod, a water pressure control piece, a water way control sealing piece and a capillary hole forming element. The water pressure control piece forms a water pressure cavity with a first opening and a second opening. An auxiliary water outlet and a main water outlet are formed in the side face of the valve shell, wherein one end is a water inlet end. The water pressure control piece and the water way control sealing piece are arranged in the valve shell in a sleeved mode. The water way control sealing piece is provided with a deforming part which is directly or indirectly matched with the main water outlet of the valve shell in a sealing mode. The capillary hole forming element is arranged on the water way control sealing piece in a sleeved mode, and a capillary hole for being communicated with the water pressure cavity and the water inlet end of the valve shell is formed. The first opening of the water pressure cavity is communicated with the auxiliary water outlet of the valve shell. The control rod is movably arranged the water pressure control piece in a sleeved mode and is provided with a sealing part. The first opening is opened or sealed by the fact that the sealing part moves in the axial direction along with the control rod. The water way control valve comprises a valve body and the valve element. The water way control valve has the advantages that operation force is small, and operation stroke is short.

Owner:JOMOO KITCHEN & BATHROOM

Laver breeding method

InactiveCN110800603AEasy to operateReduce the cost of farmingCultivating equipmentsSeaweed cultivationAnimal scienceEngineering

The invention discloses a laver breeding method, which includes the following steps: (10) fixing floating balls on cross rods to form floating ball carriers; (20) arranging a plurality of floating ball carriers transversely along the length direction of a breeding net; (30) in a pair of cables, respectively tying, by a first cable and a second cable, with a front floating ball carrier, and tying the free ends of the two cables together to form a first connection knot; and in other pair of cables, respectively tying, by a first cable and a second cable, with a rear floating ball carrier, and tying the free ends of the two cables together to form a second connection knot; (40) respectively connecting two third cables with the first and second connection knots; (50) planting laver seedlings in the breeding net; (60) respectively fixing the free ends of the two third cables on front and rear column piles, with the floating ball carriers on the upper side and the breeding net on the lower side; and (70) during the breeding period, hooking and lifting the distal ends of the cross rods of the front or rear floating ball carriers to one side of people by manually adopting a pull rod on oneside of the breeding net every day, so as to enable the floating ball carriers to rotate to turn over the breeding net to expose the laver seedlings to sunlight for a certain period of time.

Owner:汕头市佳盛食品科技有限公司

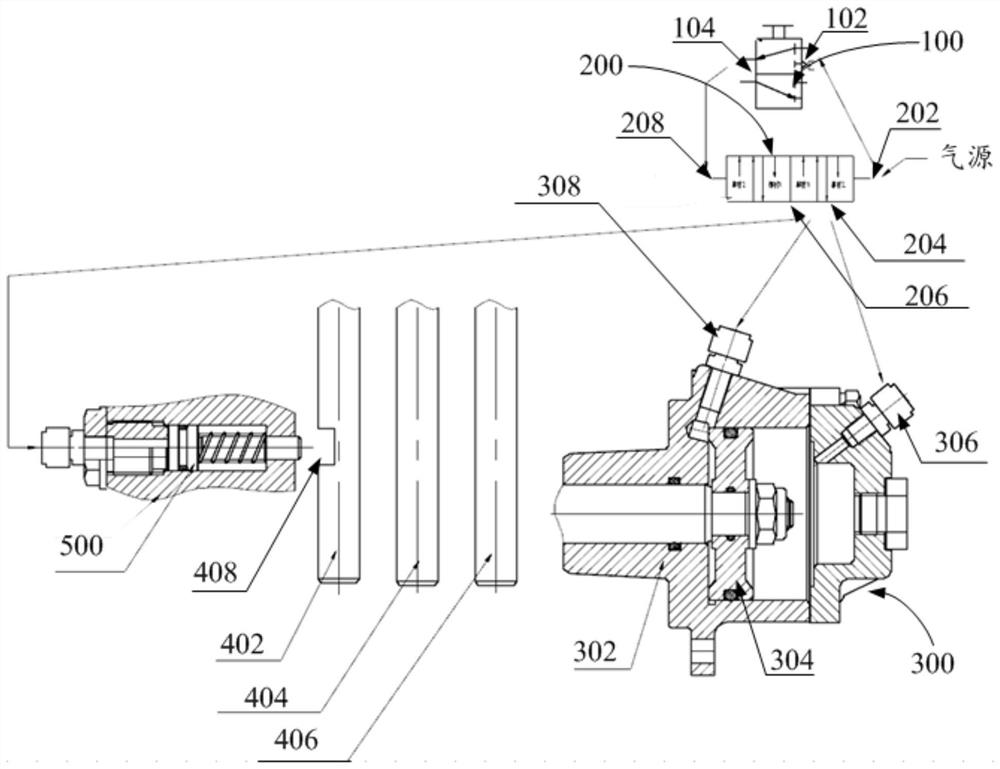

Gear shifting mechanism, transmission and vehicle

PendingCN113639039AIn line with the N-type shift control ideaImplement low-speed shiftingControlled membersGearing controlControl theoryMechanical engineering

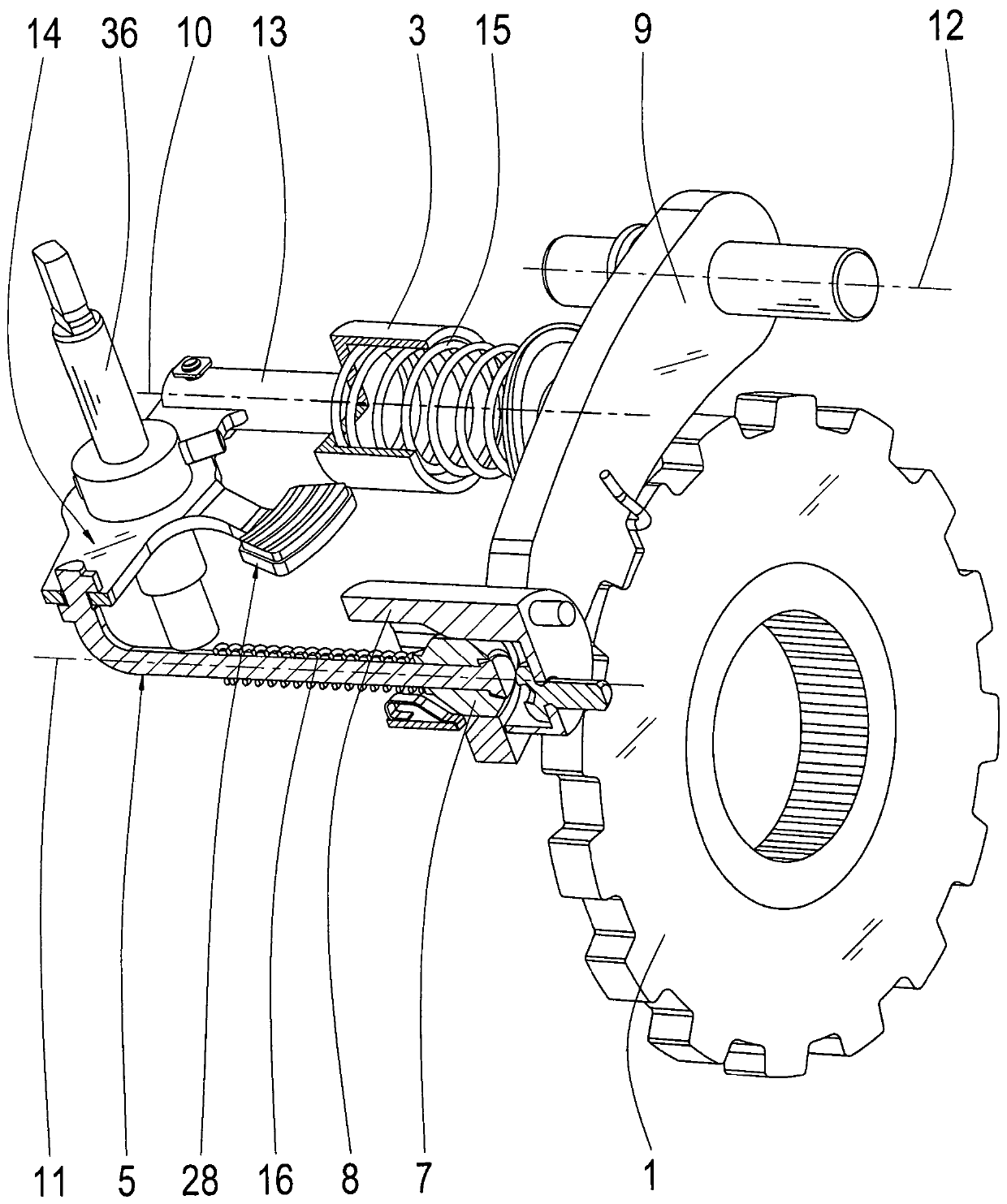

The invention provides a gear shifting mechanism, a transmission and a vehicle, wherein the gear shifting mechanism comprises a control device, a control air cylinder, a gear shifting device and gear fork shafts; the control air cylinder is connected with the control device, and the control air cylinder is configured to be suitable for acting under the control of the control device; the gear shifting device comprises at least two gear shifting structures, the at least two gear shifting structures are each provided with a plurality of gears, the at least two gear shifting structures are connected with the control air cylinder, and the gear shifting device is configured to be suitable for driving one of the at least two gear shifting structures to output multiple gears under the action of the control air cylinder; and the gear fork shafts are connected with the control device, and each gear fork shaft is configured to be suitable for being driven by the control device to be matched with one of the multiple gears for gear shifting. According to the gear shifting mechanism, each gear fork shaft can be matched with four gears for gear shifting, the action stroke of each time of gear shifting can be shortened, and a user can operate and use the gear shifting mechanism conveniently.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

Cavity tube adjusting instrument

PendingCN114366216AAdjust cross sectionQuick and accurate adjustmentSurgeryMedicineMechanical engineering

The invention provides a cavity tube adjusting instrument. The cavity tube adjusting instrument comprises a body, a first surrounding piece and a second surrounding piece, the first surrounding piece and the second surrounding piece can be combined with each other to form a surrounding part capable of surrounding a target lumen in the circumferential direction; the first surrounding piece and the second surrounding piece can synchronously move in a reciprocating mode relative to the body so as to adjust the sectional area of the surrounding part, and the cross section of the target cavity tube can deform to different degrees according to the different sectional areas of the surrounding part. Therefore, the flow rate of the liquid in the target cavity tube can be conveniently and accurately regulated and controlled, and the flow rate regulating device has the advantage of being short in operation stroke.

Owner:THE NAVAL MEDICAL UNIV OF PLA +1

Household elevator safety door locking device

The invention relates to the technical field of elevator door locks, and relates to a household elevator safety door locking device. A positioning switch is arranged at one side of a fish mouth type buckle, a contact of the positioning switch is matched with the side wall of the fish mouth type buckle, the other end of the inner side of the box body is fixedly provided with a signal input interface through a cross-shaped screw, a traction electromagnet and a double-contact switch are arranged between the fish mouth type buckle and the signal input interface in sequence, one end of the traction electromagnet is arranged in the middle of one side of the fish mouth type buckle, an inserting groove at the other end of the traction electromagnet is connected with an extension portion of a limit switch seat in an inserting mode, a limit switch is fixed on the limit switch seat, and a contact of the limit switch is matched with the double-contact switch. The household elevator safety door locking device is simple in structure, reasonable design, convenient to install and debug, high in safety, and favorable for popularization and use.

Owner:NANTONG YAO TELEI ELEVATOR PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com