A carbon material roasting and graphitization production line hoisted by bridge lifting equipment

A kind of lifting equipment and graphitization technology, applied in the direction of walking bridge cranes, cranes, lighting and heating equipment, etc., can solve the problems of inconvenient operation and maintenance of staff, occupying the usable area of the processing workshop, affecting the baking of graphite electrodes, etc. Improve processing efficiency, reduce floor space, and achieve the effect of precise grasping and placing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

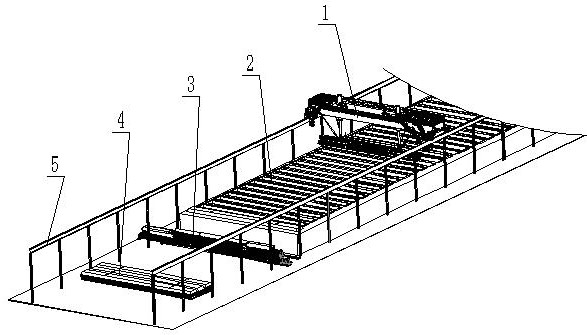

[0059] Embodiment 1, please refer to the appended figure 1 , 2 , 4, 6, 7, 10, 13, 16, a carbon material roasting and graphitization production line hoisted by bridge-type lifting equipment, including graphite electrode grouping equipment 3 arranged in sequence along the running direction of bridge-type lifting equipment 1 and Roasting furnace 2, graphite electrode marshalling equipment 3 is used to carry out series marshalling and sheeting operations on graphite electrodes, and bridge lifting device 1 is used to grab and lift graphite electrode marshalling and adding sheets in graphite electrode marshalling equipment 3, and place It is put into the roasting furnace 2 for roasting processing. In order to facilitate the effective grabbing and lifting of the graphite electrode by the bridge lifting device 1 and the subsequent unloading and feeding, the graphite electrodes grouped by the graphite electrode grouping device 3 and the bridge crane Equipment 1 and roasting furnace 2 ...

Embodiment 2

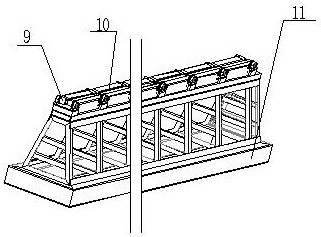

[0063] Embodiment 2, please refer to the appended image 3 , 8 And 9, in order to enable the transmission frame 11 and the bracket frame 31 to transport the graphite electrodes stably and effectively, the transmission frame 11 and the bracket frame 31 are evenly arranged with several rolling conveying parts 9 for transporting the graphite electrodes in an orderly manner, The rolling conveying member 9 includes a conveying roller 32 and a drive reduction motor 35. The conveying roller 32 is composed of two cone-shaped rollers, and the small-diameter ends of the two tapered rollers are arranged oppositely. With the bracket frame 31 top, one end of the conveying roller 32 is provided with a driving sprocket 33, and the transmission frame 11 and the bracket frame 31 side are provided with a driving reduction motor 35 corresponding to the conveying roller 32, and the output end of the driving reduction motor 35 passes through The drive chain 34 is driven and connected with the dri...

Embodiment 3

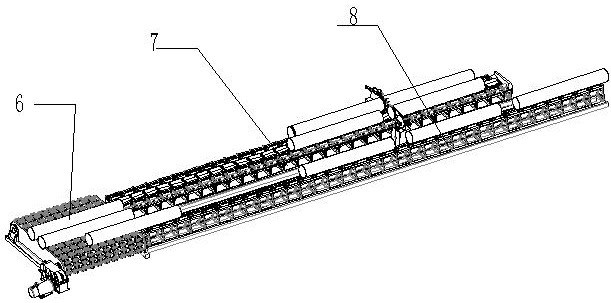

[0066] Embodiment three, please refer to the appended Figure 4 , 5 , 6, 7 and 8, in order to realize the driving connection of the drive frame 13 and the conveyor chain frame 23, the drive frame 13 includes two symmetrically arranged side plates 20, transmission shaft 18, transmission gear 17, supporting wheel shaft 16 and drive mechanism 14, two Two transmission shafts 18 are rotationally connected between the symmetrically arranged side plates 20, and the two transmission shafts 18 are located at both ends of the opposite surfaces of the two side plates 20 respectively. The transmission gear 17 meshed with the frame 23, several supporting wheel shafts 16 for supporting the conveyor chain frame 23 are arranged between the two transmission shafts 18, and the two ends of the supporting wheel shaft 16 are respectively connected to the opposite surfaces of the two side plates 20 in rotation, and the side plates One side of the plate 20 is provided with a driving mechanism 14 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com