Direction switch assembly of a forklift

A direction switch and assembly technology, applied in the direction of the lifting device, etc., can solve the problems of large stroke, large space, unfavorable operation of the driver, etc., and achieve the effect of small operation stroke, small installation space and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

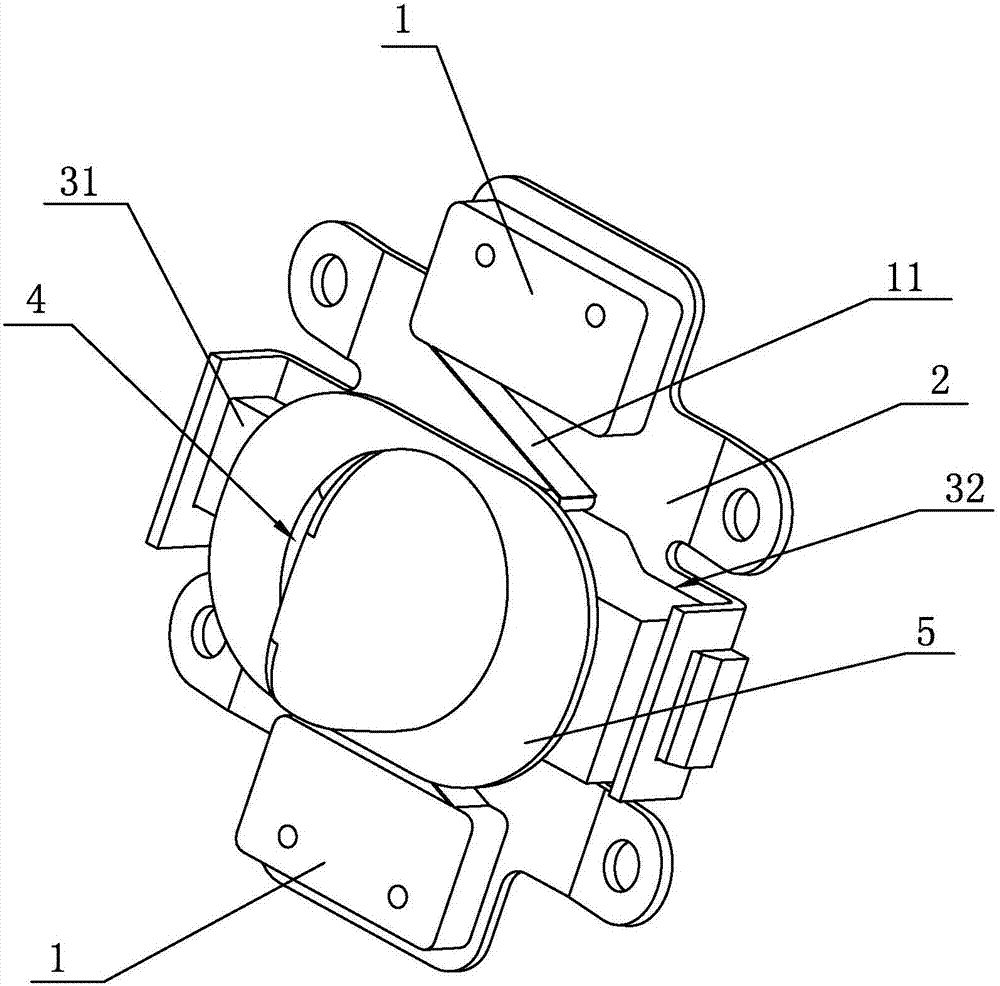

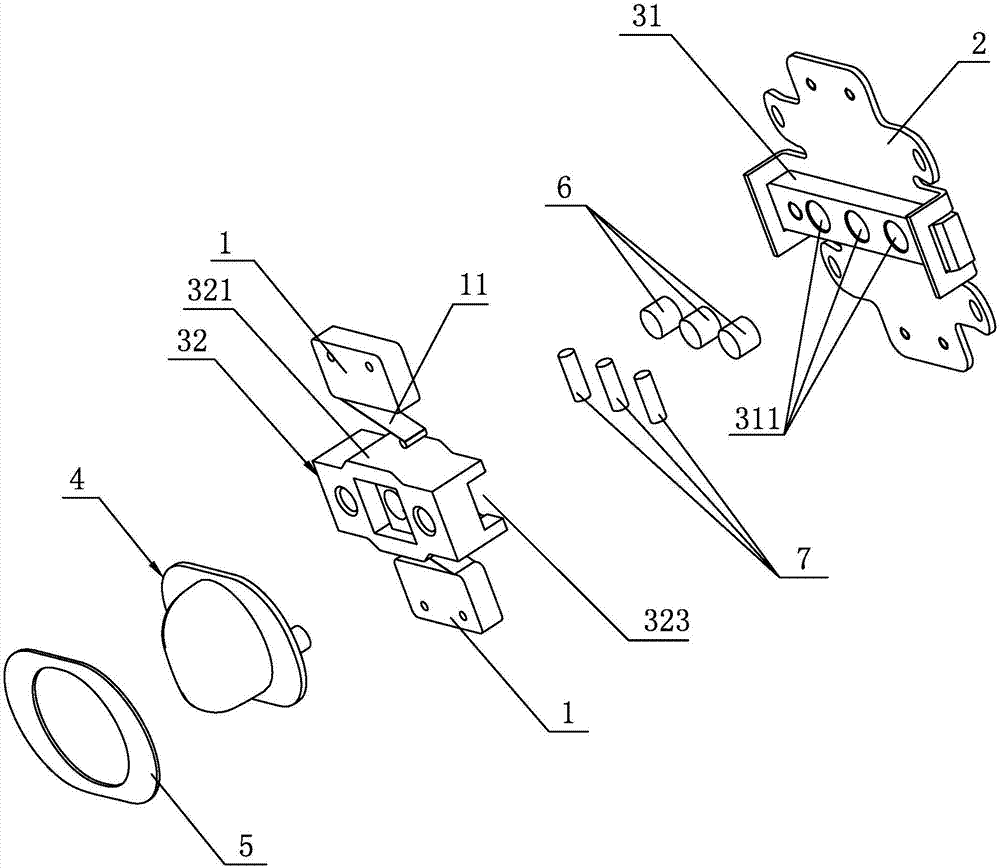

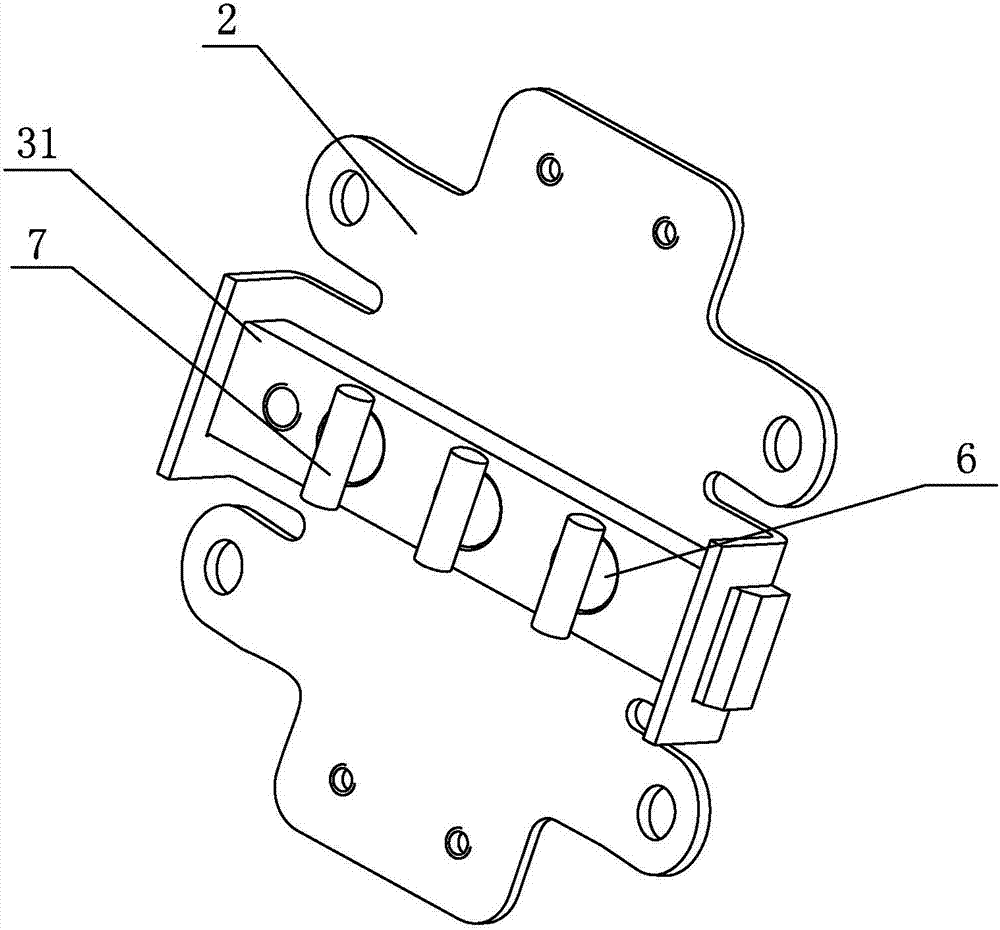

[0027] A direction switch assembly of a forklift proposed in this embodiment, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6As shown, it includes two direction switches 1, a fixing plate 2 for fixing the direction switch assembly, and a shift mechanism for making the direction switch assembly in the middle gear, left gear or right gear , the toggle piece 4 operated by the driver, the dust-proof sheet 5 that is pressed outside the toggle piece 4 to prevent dust from entering the inside of the shift mechanism, the direction switch 1 has a control rod 11, and the shift mechanism is arranged horizontally on the fixed plate 2 The guide rail 31 on the middle position of the guide rail 31 and the slide block 32 matched with the guide rail 31 are composed, the upper side end face and the lower side end face of the slide block 32 are uniformly provided with a protrusion 321 at the middle position, and the height and direction of the protrusion 321 T...

Embodiment 2

[0033] The direction switch assembly of a forklift proposed in this embodiment specifically defines the structure of the toggle member in the direction switch assembly of a forklift proposed in Embodiment 1, that is, as Figure 7 As shown, the shifting member 4 is made up of a positioning plate 41 and a shifting block 42 installed on the front of the positioning plate 41, and a device for connecting the positioning plate 41 and the sliding block 32 is provided between the reverse side of the positioning plate 41 and the front of the slider 32. The positioning component. Here, the positioning plate 41 plays a role of connecting the toggle piece 4 and the slider 32, and the toggle piece 42 serves as an external force applying component.

[0034] In this specific embodiment, the positioning assembly includes at least two positioning holes 324 disposed on the front side of the slider 32 and a positioning post 411 disposed on the reverse side of the positioning plate 41 to match th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com