Deep groove ball bearing retainer dismantling method

A deep groove ball bearing and cage technology, applied in the field of cage disassembly, can solve problems such as damage to qualified parts, damage to the roughness and roundness of the bearing steel ball raceway, and inability to re-use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

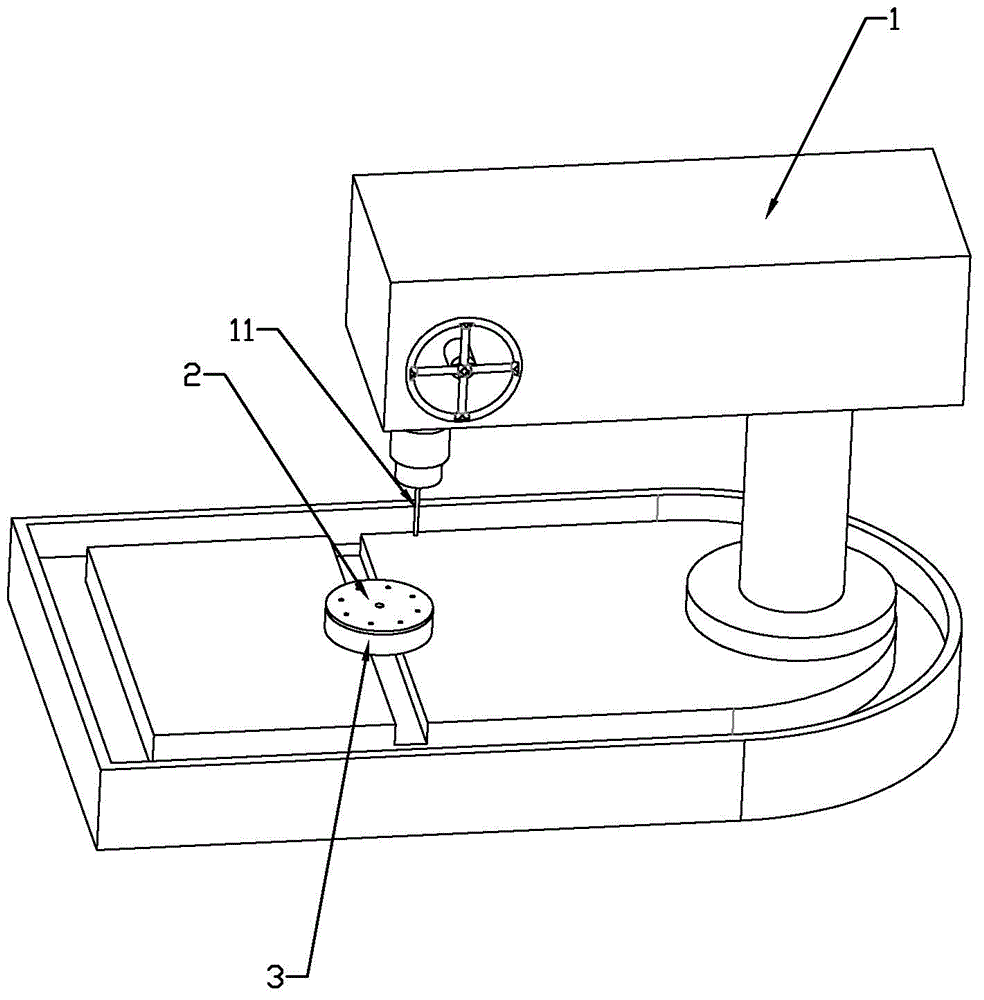

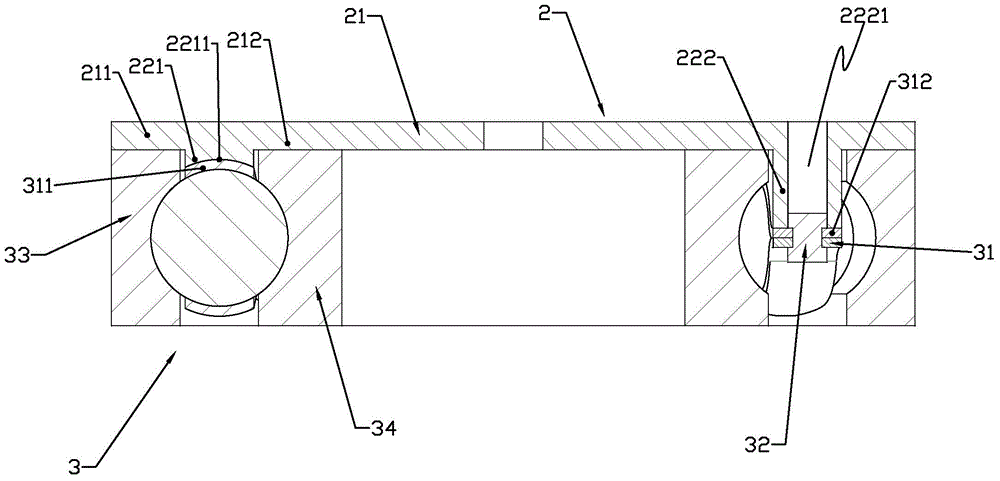

[0019] like Figure 1~3 As shown, a deep groove ball bearing cage removal method disclosed in the present invention uses bearing removal auxiliary tooling 2 to position and support the cage of the deep groove ball bearing to prevent the cage from rotating, and then place it on the workbench of the drilling machine 1, The drill bit of the drilling machine 1 removes all the rivet head cuttings from the cage of the deep groove ball bearing 3, so that the two frames of the cage of the deep groove ball bearing 3 are separated to complete the disassembly.

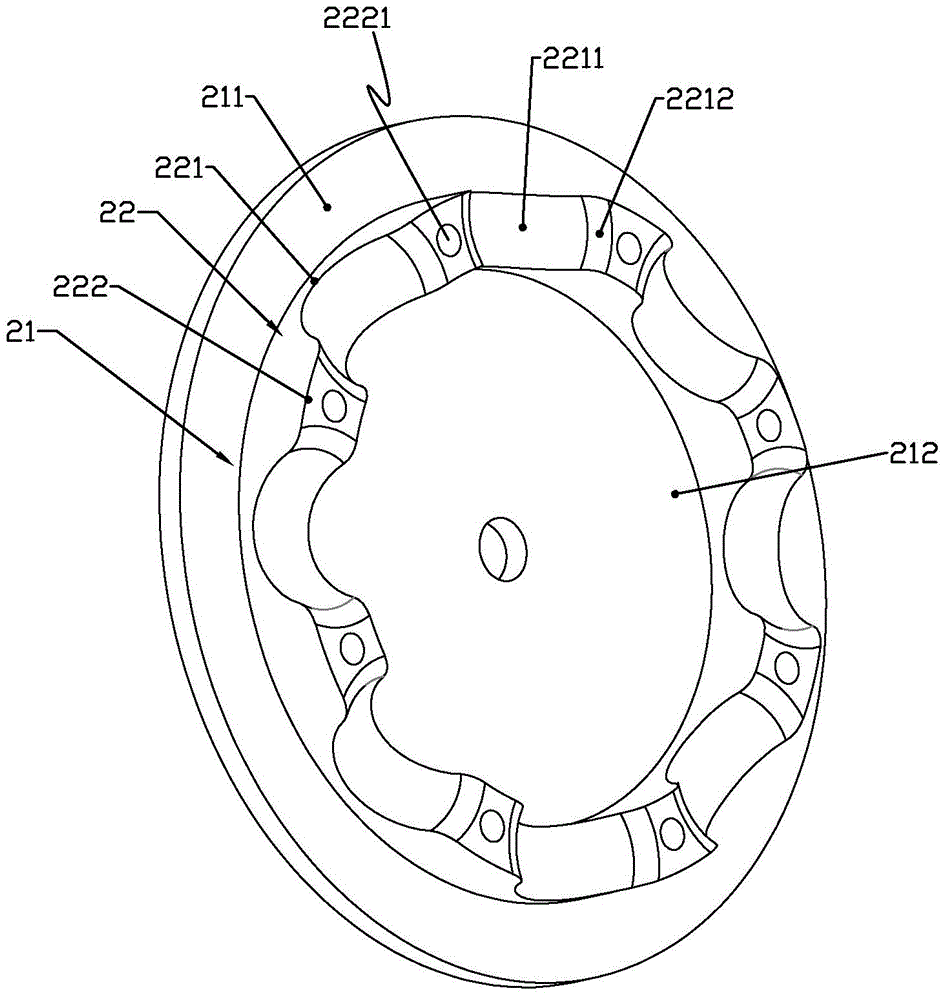

[0020] Further, the bearing removal auxiliary tooling used in the present invention is as follows: the bearing removal auxiliary tooling 2 includes a base plate 21, and the base plate 21 is provided with an annular retainer positioning boss 22, and the retainer positioning boss 22 is positioned by a spherical surface. The support part 221 and the cage beam positioning support part 222 are arranged alternately in order to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com