Gear shifting mechanism, transmission and vehicle

A technology of shifting mechanism and shifting box, which is applied to vehicle components, vehicle gearboxes, instruments, etc., can solve problems such as affecting the driver's manipulation, long shifting range, and unsmooth gear arrangement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

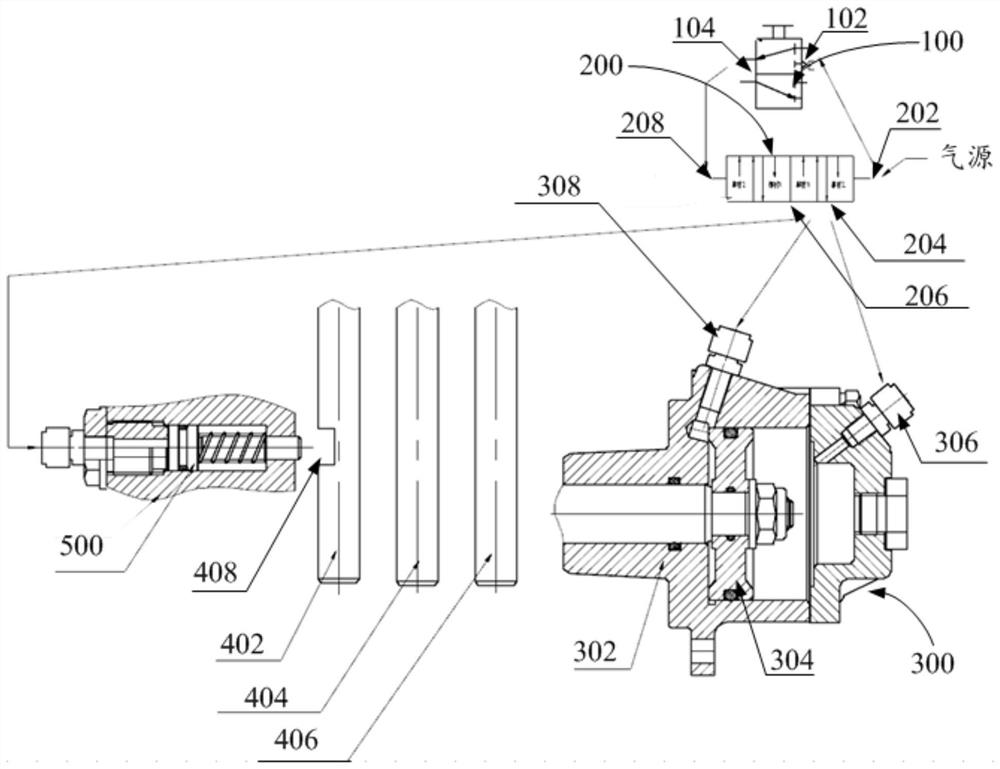

[0045] Such as figure 1 As shown, the present invention firstly proposes a shifting mechanism, including: a control device, an operating cylinder 300, a shifting device and a fork shaft.

[0046] Wherein, the shifting device includes at least two shifting structures, and each shifting structure is provided with a plurality of gears, and at least two shifting structures are connected with the operating cylinder 300, and can be operated under the action of the operating cylinder 300. switch position; the operating cylinder 300 is connected with the control device, and can act under the control of the control device, and then drive one of the gear shifting structures to work and output multiple gear positions; the fork shaft is connected with the control device, and the fork shaft can be in the Driven by the control device, it cooperates with one of the multiple gears provided by the gear shifting device to shift gears, thereby realizing gear shifting.

[0047] In particular, th...

Embodiment 2

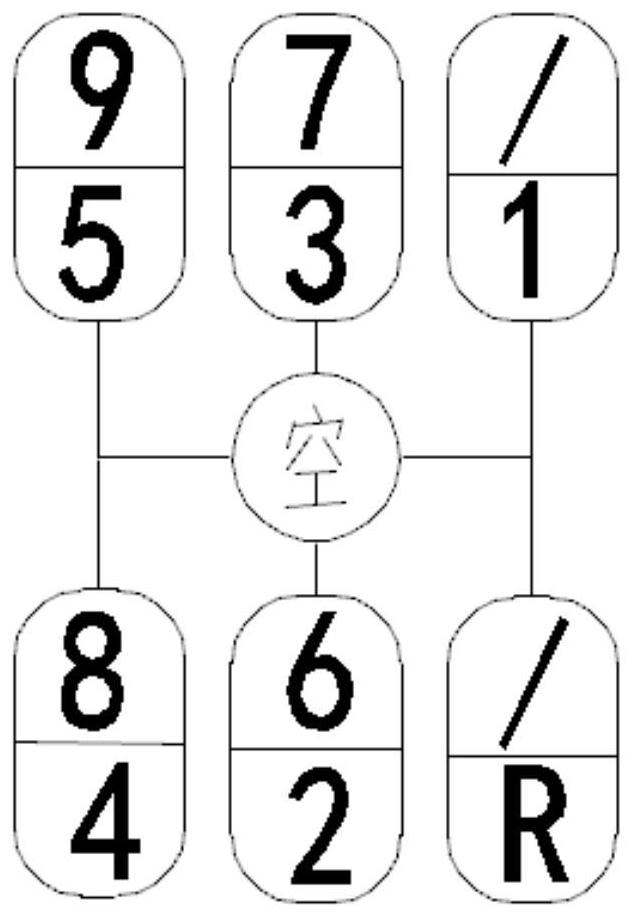

[0050] Such as figure 1 with figure 2 As shown, the second one of the present invention proposes a shifting mechanism, including: a control device, an operating cylinder 300, a shifting device and a fork shaft; the shifting device includes a shifting box, a first shifting structure and a second shifting mechanism blocking structure.

[0051] Wherein, the shifting device includes a first shifting structure and a second shifting structure, each shifting structure is provided with a plurality of gear positions, and both shifting structures are connected with the operating cylinder 300, and can be operated on the operating cylinder The position is switched under the action of 300; the operating cylinder 300 is connected to the control device, and can act under the control of the control device, and then drive the first shifting structure or the second shifting structure to work and output multiple gears; the fork shaft and The control device is connected, and the fork shaft can...

Embodiment 3

[0075] The third embodiment of the present invention proposes a transmission, including: the shifting mechanism as in the first or second embodiment (this embodiment is not shown in the figure).

[0076] The transmission proposed in this embodiment includes the shifting mechanism of the first or second embodiment above. Therefore, it has all the beneficial effects of the above-mentioned shifting mechanism, which will not be stated one by one here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com