Preparation method of impurity compound in ramelteon and prepared standard substance

A technology of ramelteon and compound, applied in preparation method and prepared standard, in the field of quality analysis and inspection of medicine ramelteon, and can solve the problem that there is no compound of formula (I) and/or formula (II), There are no problems such as preparation and sales of standard compounds of formula (I) and/or formula (II), and the effects of easy availability of raw materials, low cost and suitable yield are achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Step 1, preparation of ramelteon damage sample

[0081] Take 20 grams of ramelteon raw material (manufactured by Zhuhai United Laboratories Co., Ltd., batch number 140218), and place it at 160° C. for 2 hours to generate the impurities.

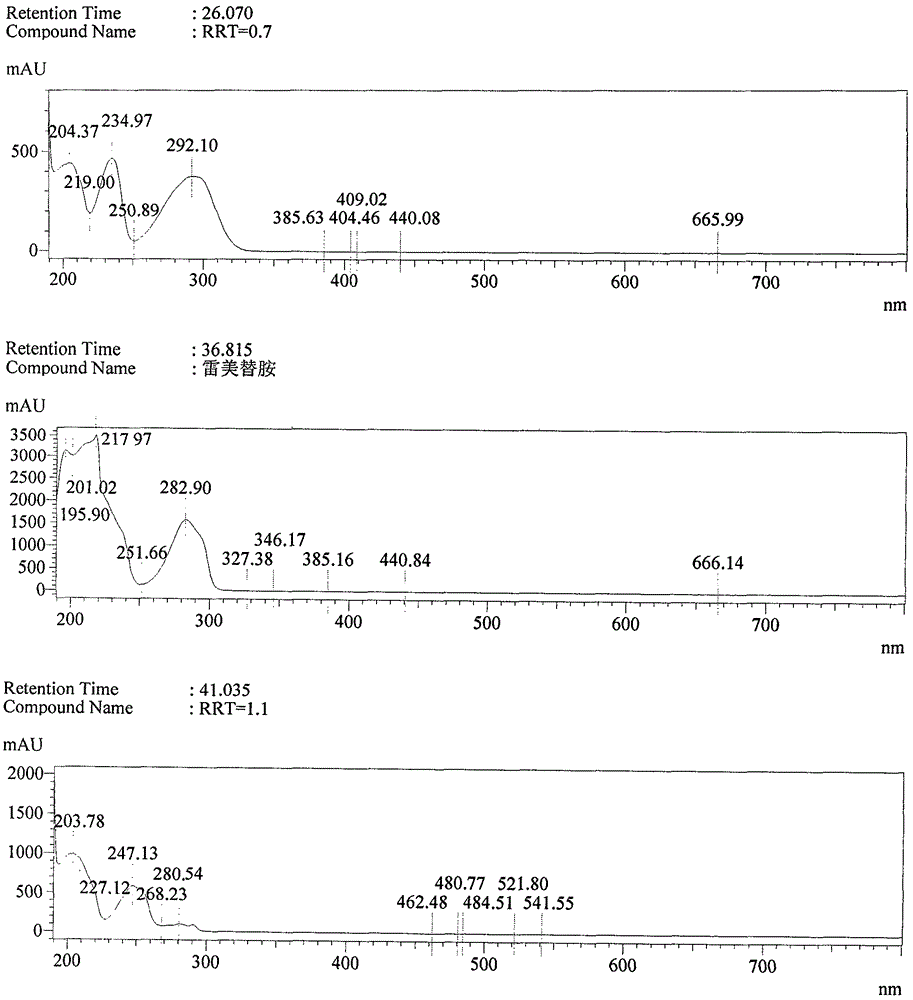

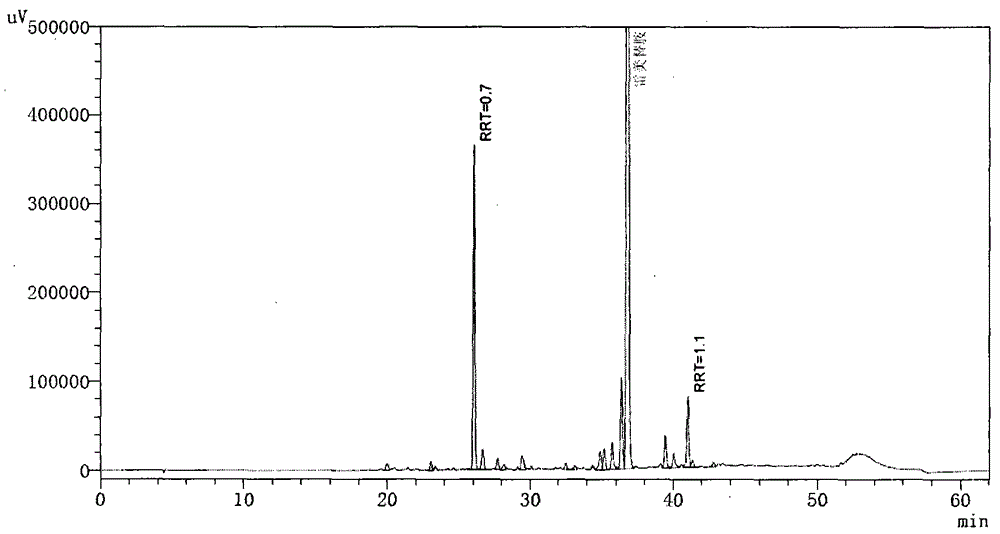

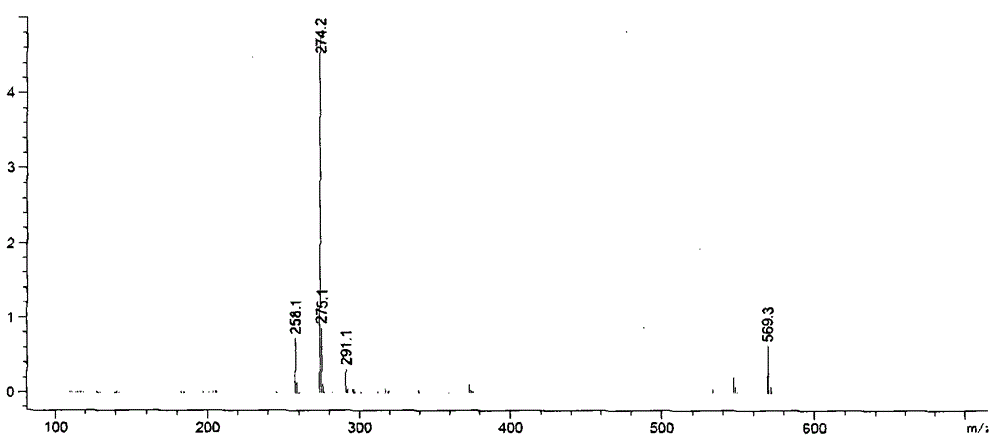

[0082] Step 2, HPLC Determination of Ramelteon Destruction Sample

[0083] High performance liquid chromatography: Shimadzu 20A HPLC (equipped with DAD detector);

[0084] Chromatographic column: Hypersil GOLD 5μ250×4.6mm;

[0085] Mobile phase A: 0.1% formic acid solution; Mobile phase B: acetonitrile;

[0086] Gradient: 0min (A: 90%, B: 10%), 5min (A: 90%, B: 10%), 45min (A: 40%, B: 60%), 50min (A: 10%, B: 90%), 51min (A: 90%, B: 10%), 60min (A: 90%, B: 10%);

[0087] Flow rate: 0.8ml / min;

[0088] Injection volume: 20μL;

[0089] Detection wavelength: 288nm.

[0090] Get above-mentioned destruction sample appropriate amount, be mixed with the solution that contains ramelteon about 2mg / ml with 50% acetonitrile-water, sample in...

Embodiment 2

[0116] Step 1, preparation of ramelteon damage sample

[0117] Take 10 grams of ramelteon raw material (manufactured by Zhuhai United Laboratories Co., Ltd., batch number 140218), and place it at 180° C. for 3 hours to generate the impurities.

[0118] Step 2, HPLC Determination of Ramelteon Destruction Sample

[0119] High performance liquid chromatography: Shimadzu 20A HPLC (equipped with DAD detector);

[0120] Chromatographic column: Hypersil GOLD 5μ250×4.6mm;

[0121] Mobile phase A: 0.1% formic acid solution; Mobile phase B: acetonitrile;

[0122] Gradient: 0min (A: 90%, B: 10%), 5min (A: 90%, B: 10%), 45min (A: 40%, B: 60%), 50min (A: 10%, B: 90%), 51min (A: 90%, B: 10%), 60min (A: 90%, B: 10%);

[0123] Flow rate: 0.8ml / min;

[0124] Injection volume: 20μL;

[0125] Detection wavelength: 288nm.

[0126] Get above-mentioned destruction sample appropriate amount, be mixed with the solution that contains ramelteon about 2mg / ml with 50% acetonitrile-water, sample in...

Embodiment 3

[0145] Step 1, preparation of ramelteon damage sample

[0146] Take 10 grams of ramelteon raw material (manufactured by Zhuhai United Laboratories Co., Ltd., batch number 140218), and place it at 140° C. for 1.5 hours to generate the impurities.

[0147] Step 2, HPLC Determination of Ramelteon Destruction Sample

[0148] High performance liquid chromatography: Shimadzu 20A HPLC (equipped with DAD detector);

[0149] Chromatographic column: Hypersil GOLD 5μ250×4.6mm;

[0150] Mobile phase A: 0.1% formic acid solution; Mobile phase B: acetonitrile;

[0151] Gradient: 0min (A: 90%, B: 10%), 5min (A: 90%, B: 10%), 45min (A: 40%, B: 60%), 50min (A: 10%, B: 90%), 51min (A: 90%, B: 10%), 60min (A: 90%, B: 10%);

[0152] Flow rate: 0.8ml / min;

[0153] Injection volume: 20μL;

[0154] Detection wavelength: 288nm.

[0155]Get above-mentioned destruction sample appropriate amount, be mixed with the solution that contains ramelteon about 2mg / ml with 50% acetonitrile-water, sample i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| chromatographic purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com