Hollow, semi-hollow tooth blade snow plow blade

A technology of snow shoveling and semi-hollowing, which is applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of low work efficiency and high labor intensity, and achieve the effect of simple structure, high efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

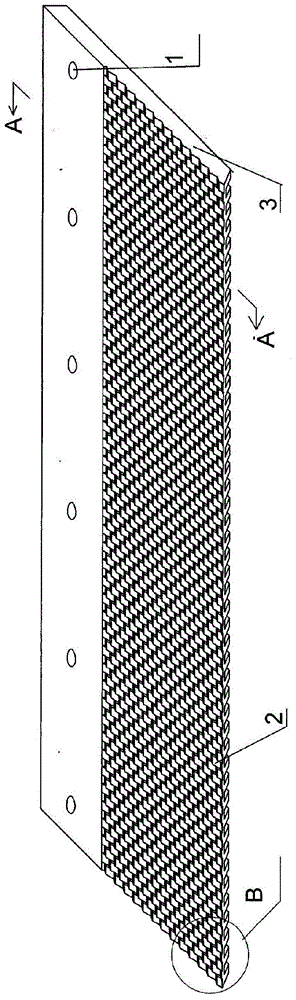

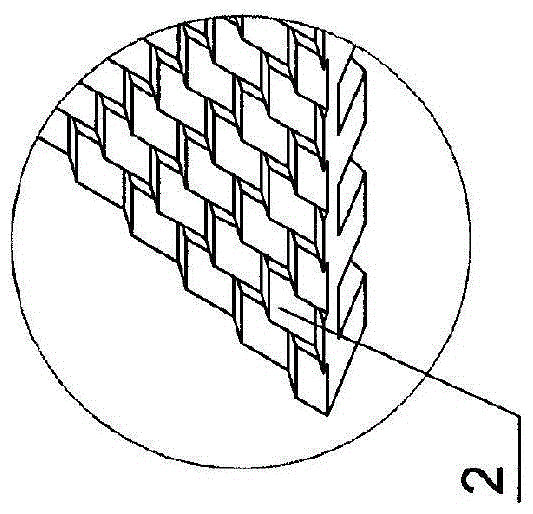

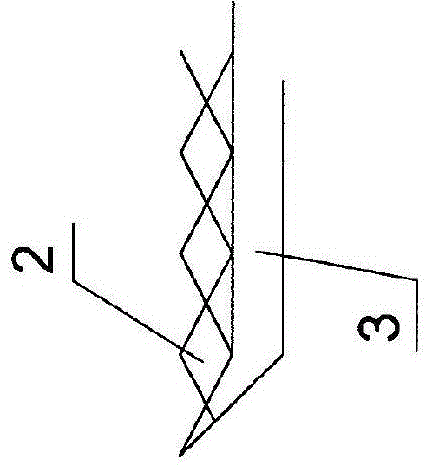

[0020] Depend on Figure 1~6 You can see the semi-hollow structure of the knife board. It is equipped with multiple rows of teeth 2 and 3 on the front of the knife board. 4. Form a semi-hollow structure. Each rectangular groove has reinforcing ribs 5 to increase the stability and strength of the main body. The reinforcing ribs are not on the same line and are staggered from each other. Installing holes 1 are provided in the rear half of the above-mentioned blade. The material of this blade is wear-resistant high manganese steel.

[0021] Depend on Figure 7-8 Can see the hollow structure of this knife plate, it is to establish the teeth 2 of many rows staggeredly arranged on the front half of knife plate, establish through-hole 6 between above-mentioned multiple rows of teeth, through-hole also is arranged in a staggered manner. Evenly arranged rectangular grooves 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com