A kiln-shaped antique brick and its production method

A production method and technology of antique bricks, applied in covering/lining, construction, building construction, etc., can solve the problems of singleness and insufficient layers, and achieve the effect of strong metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

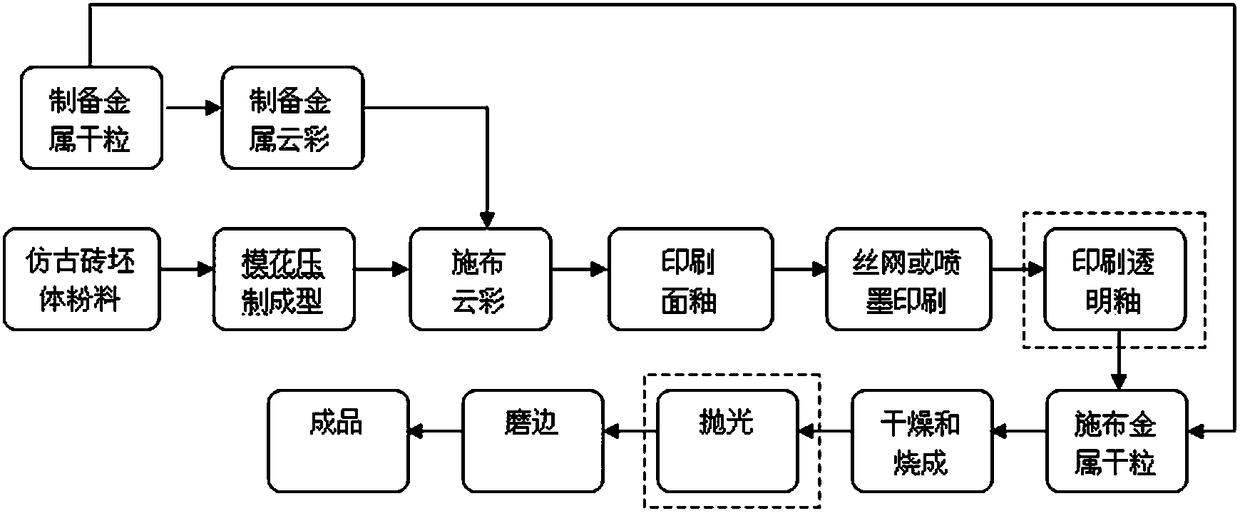

Method used

Image

Examples

Embodiment 1

[0028] 1) Preparing brick adobes: Prepare porcelain antique brick adobe powder according to conventional methods, and press molds to prepare adobes for use;

[0029] 2) Preparation of metal dry particles: according to the conventional glass frit preparation process, select lithium-containing minerals, quartz and chemical raw materials, and obtain The composition range is SiO2 25%, Al2O3 6%, Fe2O3 7%, Li2O 1%, B2O3 4%, ZnO 35%, PbO 15%, the rest is clarifying agent and impurities, and the particle size of moisture ≤ 0.5% is 100~200 Purpose frit, spare;

[0030] 3) Preparation of metal cloud: Based on the dry metal particles prepared in step 2), introduce an appropriate amount of suspending agent and debonding agent, add water and grind, control the fineness of the glaze slurry to be less than 0.05% on a 325 mesh sieve, and obtain a density of 1.3g / cm3 clouds of metal;

[0031] 4) Spreading clouds: spread metal clouds on the adobe prepared in step 1) by spraying glaze, and the...

Embodiment 2

[0038] 1) Preparing brick adobes: Prepare porcelain antique brick adobe powder according to conventional methods, and press molds to prepare adobes for use;

[0039] 2) Preparation of metal dry particles: according to the conventional glass frit preparation process, select lithium-containing minerals, quartz and chemical raw materials, and obtain The composition range is SiO2 30%, Al2O3 3%, Fe2O3 5%, Li2O 2%, B2O3 5%, ZnO 28%, PbO 18%, the rest is clarifying agent and impurities, and the particle size of moisture ≤ 0.5% is 100~ 200 mesh frit, spare;

[0040] 3) Preparation of metal cloud: Based on the dry metal particles prepared in step 2), introduce an appropriate amount of suspending agent and debonding agent, add water and grind, control the fineness of the glaze slurry to be less than 0.05% on a 325 mesh sieve, and obtain a density of 1.4g / cm3 clouds of metal;

[0041] 4) Spreading clouds: spread metal clouds on the adobe prepared in step 1) by spraying glaze, and the amo...

Embodiment 3

[0049] 1) Preparing brick adobes: Prepare porcelain antique brick adobe powder according to conventional methods, and press molds to prepare adobes for use;

[0050] 2) Preparation of metal dry particles: According to the conventional glass frit preparation process, select lithium-containing minerals, quartz and chemical raw materials, and obtain The composition range is SiO2 30%, Al2O3 6%, Fe2O3 9%, Li2O 1.5%, B2O3 2.5%, ZnO 26%, PbO 14%, the rest is clarifying agent and impurities, and the particle size of moisture <0.5% is 100~ 200 mesh frit, spare;

[0051] 3) Preparation of metal cloud: Based on the dry metal particles prepared in step 2), introduce an appropriate amount of suspending agent and debonding agent, add water and grind, control the fineness of the glaze slurry to be less than 0.05% on a 325 mesh sieve, and obtain a density of 1.1g / cm3 clouds of metal;

[0052] 4) Spreading clouds: spread metallic clouds on the adobe prepared in step 1) by throwing glaze, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com