Coal-bed gas extraction effect dynamic evaluation method

A coal seam gas and gas drainage technology, which is applied in the field of dynamic evaluation of coal seam gas drainage effect, can solve the problems of tight coal seam gas drainage period, mutual restriction, imbalance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

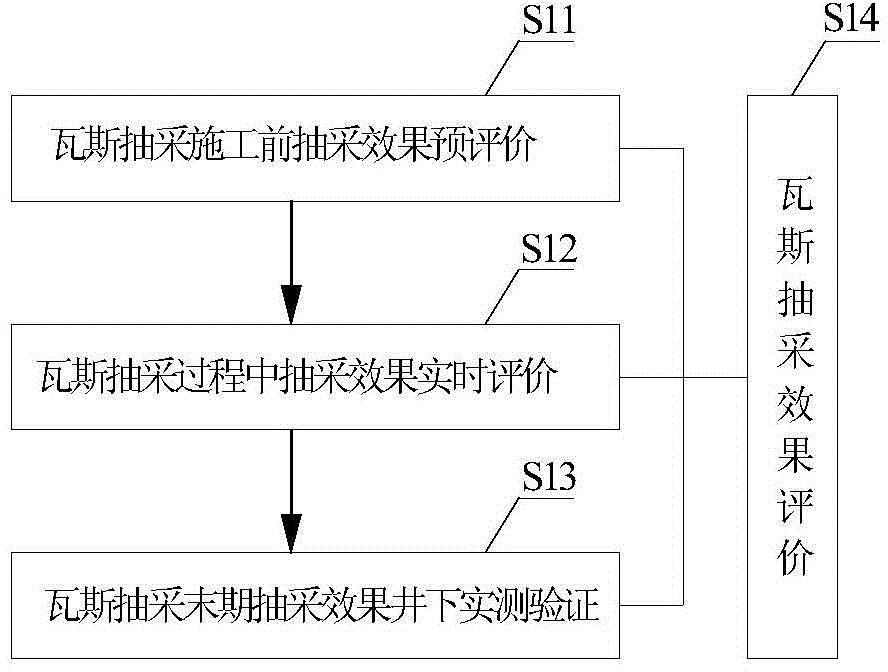

[0039] figure 1 It is a method for dynamically evaluating coal seam gas drainage effect in the present invention. Such as figure 1 As shown, the method includes the following steps:

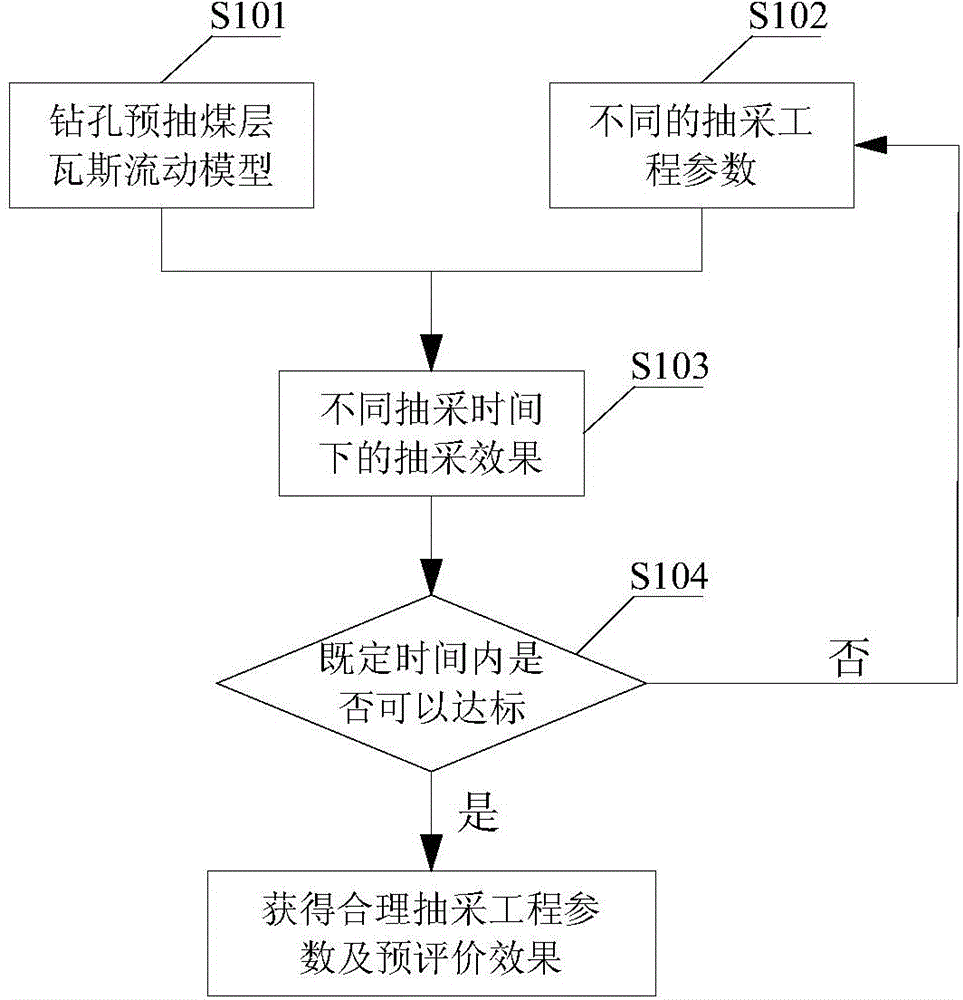

[0040] Step S11: Before the construction of the coal seam gas drainage project, pre-evaluate the coal seam gas drainage effect by using the drilling pre-drainage coal seam gas flow theory, drainage effect prediction and drainage engineering optimization methods.

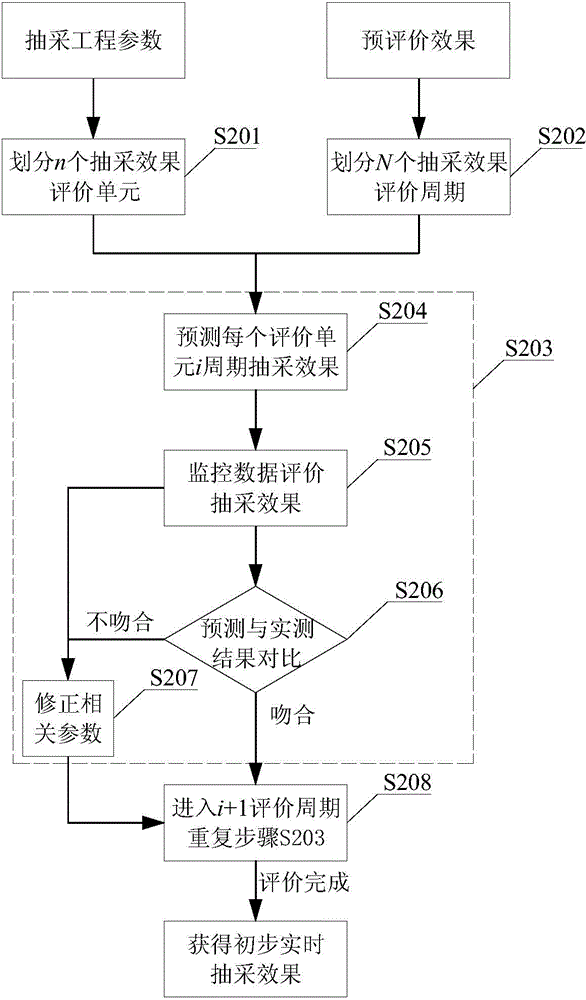

[0041] Step S12: During the coal seam gas drainage process, use the coal seam gas drainage prediction theory, drainage monitoring and monitoring technology, underground coal seam gas parameter measurement technology and mathematical inversion to evaluate the drainage effect in real time.

[0042] Step S13: At the end of the coal seam gas drainage, verify whether the drainage meets the standard thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com