Lamination anti-twist device

A lamination and anti-torsion technology, applied in the mechanical field, can solve the problems that the installation side should not bear axial load and radial load, the 4 bolts on the planetary wheel installation side are overloaded, and the test load of the rotor shaft is large, etc., to achieve Large torsional rigidity, simple assembly, and easy processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

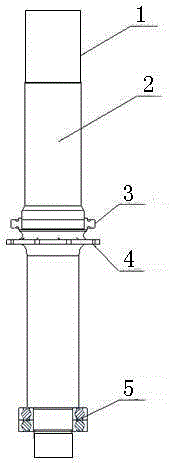

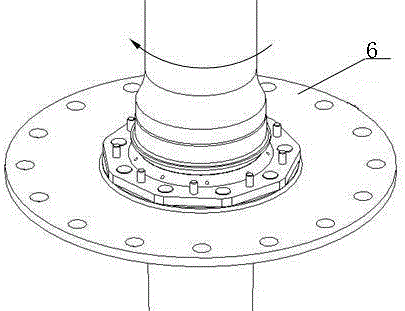

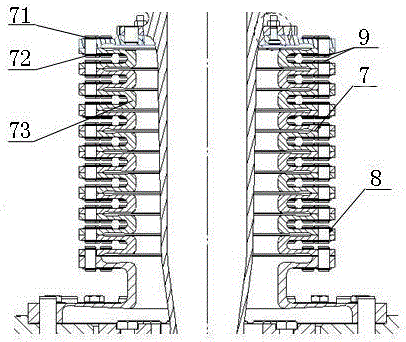

[0025] In this embodiment, the device is applied to a certain type of rotor shaft planetary gear to prevent torsion, such as figure 1 shown; as image 3 As shown, the lamination anti-torsion device of this embodiment includes a plurality of laminations 7, the laminations 7 are annular, the laminations 7 are stacked together, and the laminations 7 are connected by pins 8 and retaining rings 9; The lamination 7 includes an upper surface 71, a lower surface 72 and a connecting portion 73 connecting the upper surface 71 and the lower surface 72, the upper surface 71 is connected to the lower surface 72 of the previous lamination 7, and the lower surface 72 is connected to the lower surface 72. The upper surface 71 of one lamination 7 is connected; the upper surface 71 of the lamination 7 at the top is fixed to the component to be tested by a fastener.

[0026] Further, the connecting portion 72 is an arc-shaped structure concaved inwardly along the radial direction of the laminat...

Embodiment 2

[0033] In this embodiment, the device is applied to a certain type of rotor shaft planetary gear to prevent torsion, such as figure 1 shown; as image 3 As shown, the lamination anti-torsion device of this embodiment includes a plurality of laminations 7, the laminations 7 are annular, the laminations 7 are stacked together, and the laminations 7 are connected by pins 8 and retaining rings 9; The lamination 7 includes an upper surface 71, a lower surface 72 and a connecting portion 73 connecting the upper surface 71 and the lower surface 72, the upper surface 71 is connected to the lower surface 72 of the previous lamination 7, and the lower surface 72 is connected to the lower surface 72. The upper surface 71 of one lamination 7 is connected; the upper surface 71 of the lamination 7 at the top is fixed to the component to be tested by a fastener.

[0034] Further, the connecting portion 72 is an arc-shaped structure concaved inwardly along the radial direction of the laminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com