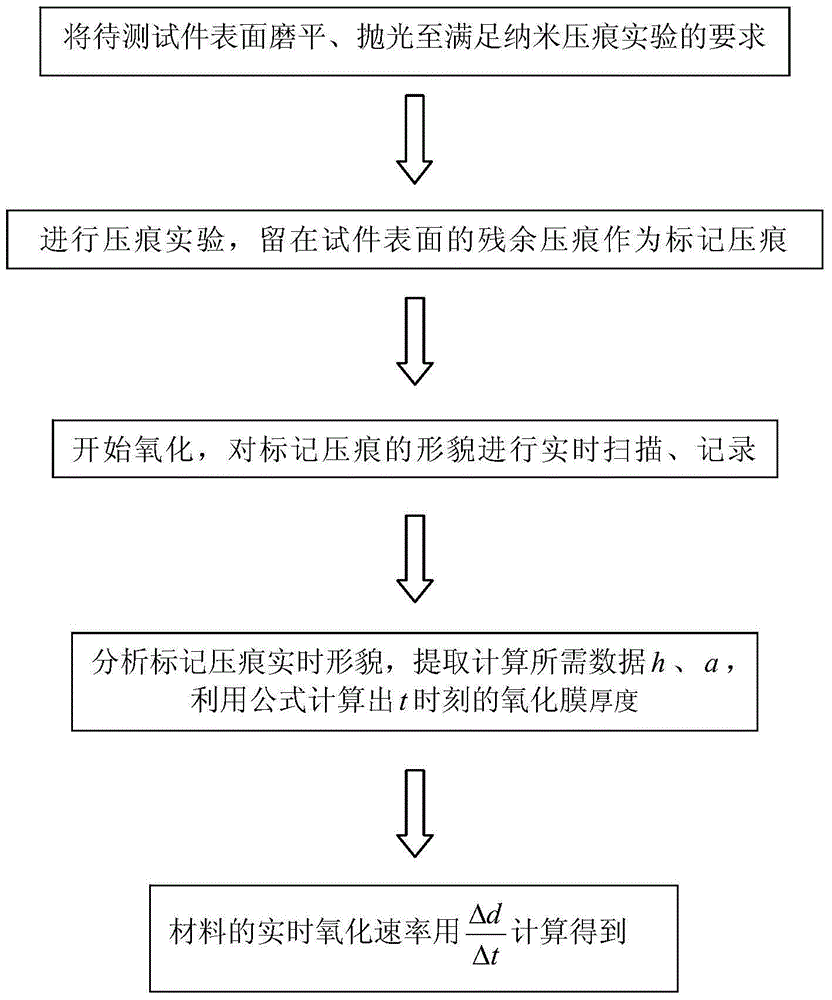

A method for real-time measurement of material oxidation rate using nanoindentation topography

A nano-indentation and oxidation rate technology, applied in measurement devices, analysis materials, material analysis by optical means, etc., can solve the problems of lack of real-time monitoring of material oxidation process, and lack of micro-scale real-time evolution data in oxidation process observation and analysis. , to achieve the effect of real-time online measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] a. Prepare the niobium 521 alloy material test piece, and polish the surface of the test piece to meet the requirements of the high-temperature nano-indentation test on the surface finish of the test piece;

[0044] b. Use the high-temperature Berkovich indenter of the high-temperature nanoindenter to press a 146nm-deep marking indentation on the surface of the test piece with a load of 7250uN at room temperature;

[0045] c. Heat the test piece to 100°C, 200°C, 300°C, 400°C, 500°C, 600°C, 700°C, the material is oxidized at high temperature, and the marked indentation is scanned in real time and in situ at each temperature point Record;

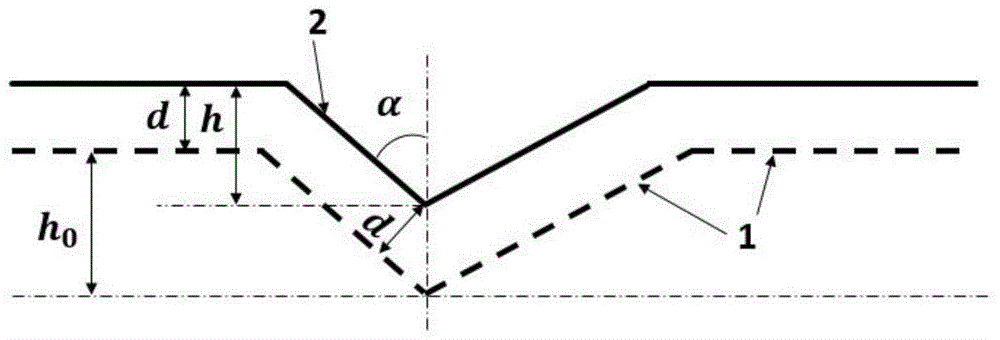

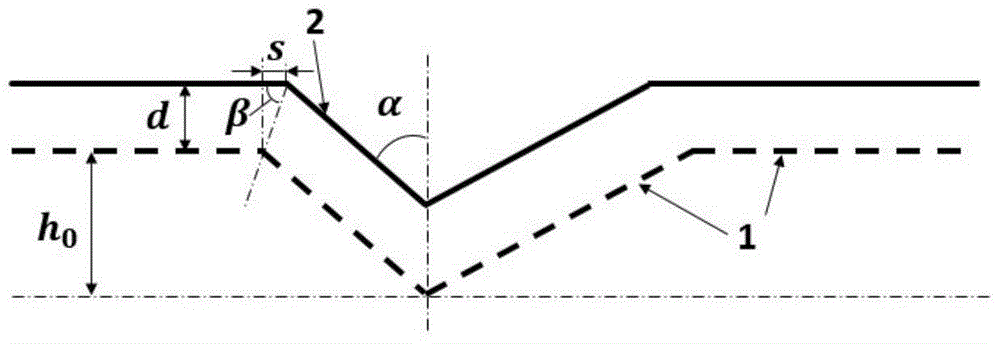

[0046] d. Use software to extract the depth h of the marking indentation at different times and the average value a of the lengths of the three sides from the real-time shape information of the marking indentation;

[0047] e. Since the thermal expansion rate of niobium 521 alloy is very small, the dimensional change caused by tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com