A pipe diameter measuring device and its measuring method based on machine vision

A diameter measurement and machine vision technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of complicated measurement devices, influence of measurement results, inability to accurately measure the outer diameter of pipes, etc., to improve measurement efficiency and ensure accuracy. and real-time, the effect of improving production efficiency

Active Publication Date: 2021-04-02

TAIYUAN UNIV OF TECH

View PDF11 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The measuring device is relatively complicated, and there are certain requirements for the fixing device of the pipe, and the position of the centerline of the pipe is also changing with the diameter of the pipe, which will have a greater impact on the measurement results

Patent CN 201488707 introduces a pipe diameter measuring device, which uses a laser to penetrate into the pipe to measure the inner diameter, but it cannot accurately measure the outer diameter of the pipe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0048]

example 2

[0050]

[0051] According to the above measurement examples, it is proved that the inventive device can effectively control the measurement error below 0.5%, and the measurement accuracy meets the production requirements.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

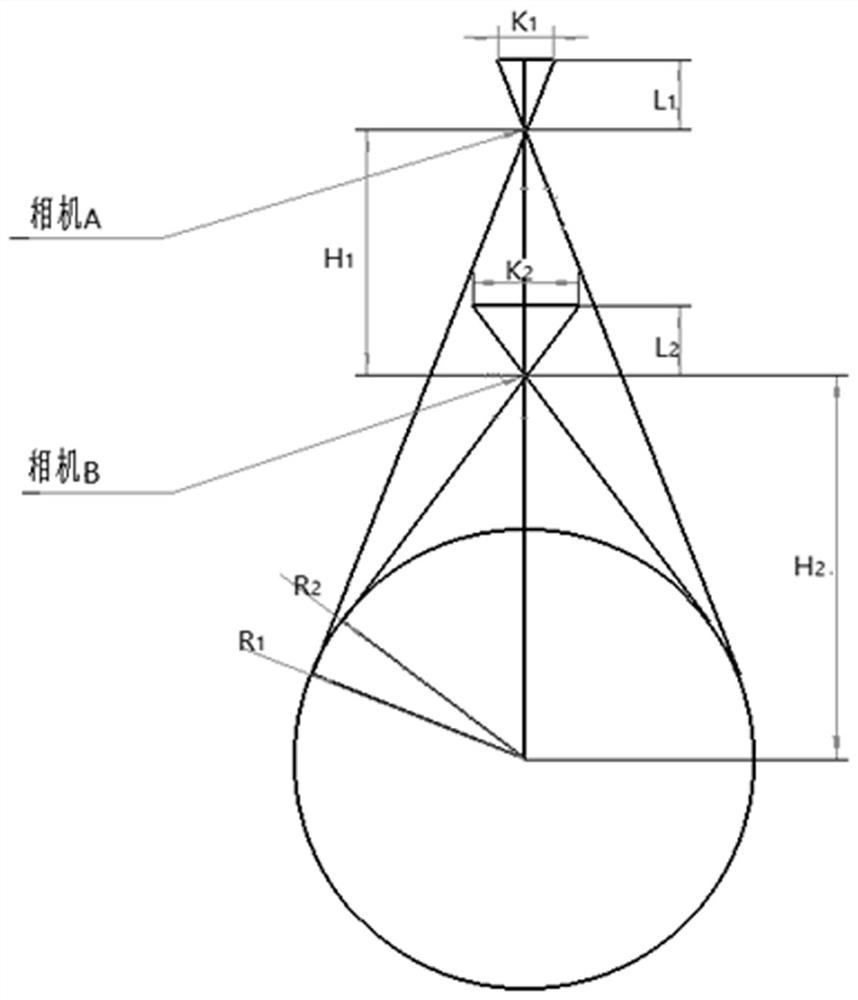

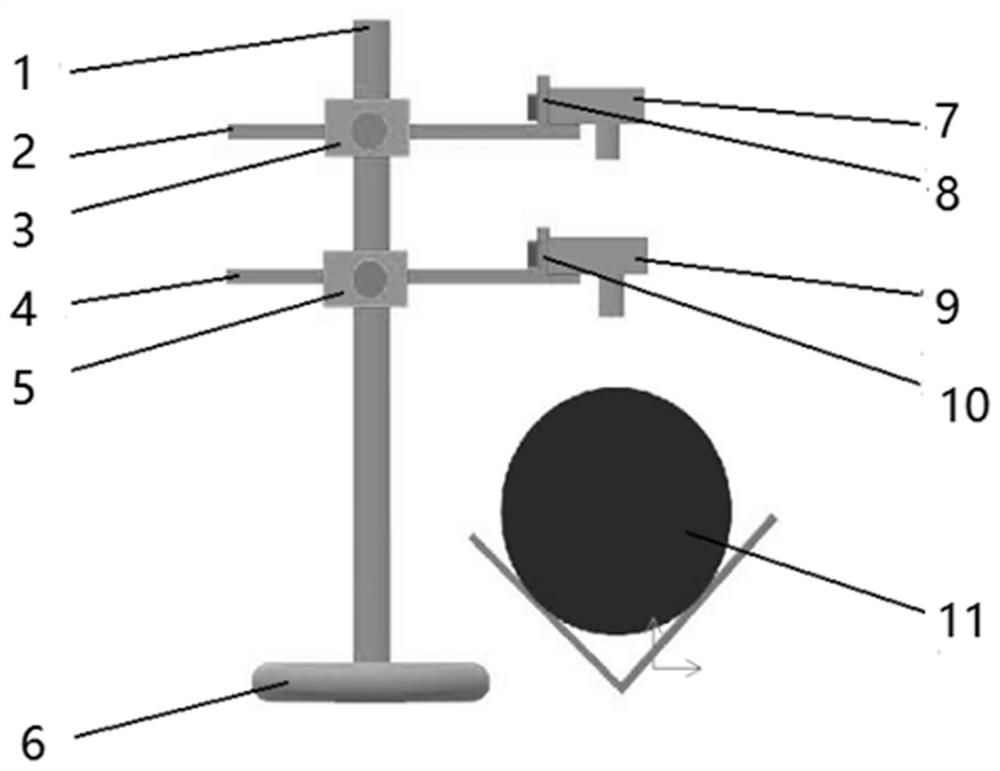

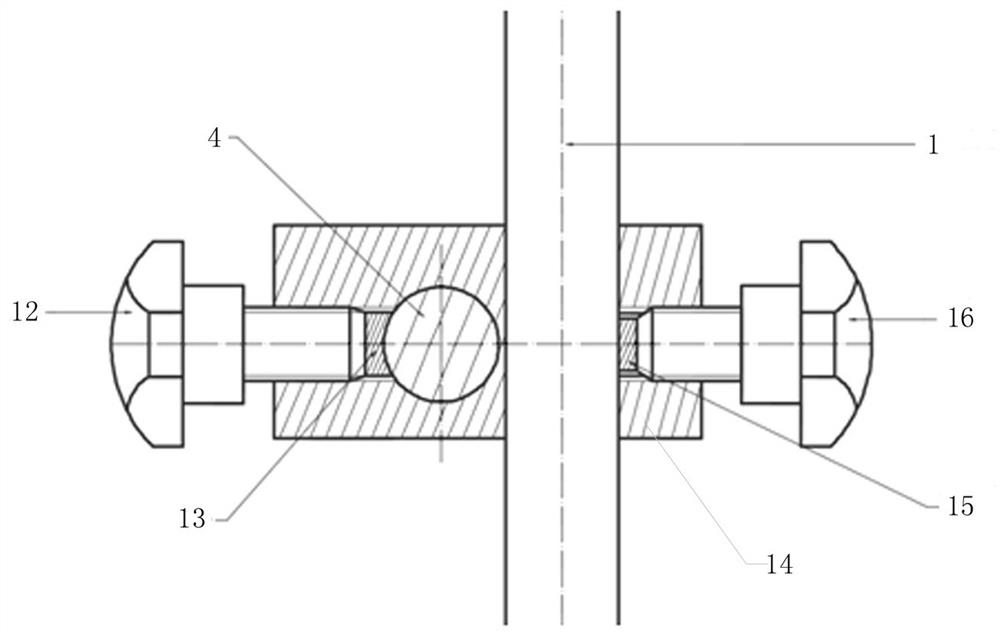

The present invention belongs to the field of pipe measurement, and discloses a machine vision-based pipe diameter measuring device and a measuring method thereof. The device comprises a vertical bracket and a chassis that are vertically connected; the bracket is horizontally connected with two upper and lower horizontal bars; the same ends of the two horizontal bars are provided with a camera respectively; the two cameras are arranged directly above the center line of a to-be-tested pipe; the two horizontal bars are adjustably arranged through a clamping device and the vertical bracket respectively; and the vertical distance of the camera from the pipe and the extended length of the camera in the horizontal direction are continuously adjusted by using the clamping device. According to thetechnical scheme of the present invention, a combination of a natural light source and two high-definition cameras are used for non-contact measurement, and the device is simple and low in cost, andcan be used to remove the measurement error caused by the runout of the center of the pipe; and real-time online measurement during the pipe operation can be realized, and even if the pipe has radialrunout during the operation, the diameter can also be accurately measured.

Description

technical field [0001] The invention relates to a machine vision-based pipe diameter measurement device and a measurement method thereof, which is a non-contact diameter measurement device and belongs to the field of pipe measurement. Background technique [0002] In the production process of pipes, especially the production of welded pipes (including straight seam and spiral seam welded pipes), due to its special production process, the diameter of welded pipes is often unstable, and the diameter error range needs to be controlled within 0.5%. In order to ensure the production quality of the product, it is necessary to measure the diameter of the moving pipe in real time. [0003] At present, most manufacturers specially send personnel to carry out manual diameter detection on the assembly line. If the diameter does not meet the requirements, they will stop the machine for detection and adjustment, which will easily cause waste products due to pipe diameter exceeding the st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B11/08

CPCG01B11/08

Inventor 陈占春孙亮于兵姚爱英

Owner TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com