A detection and alarm circuit for a stirring pot used in pharmaceutical production

An alarm circuit and a technology for pharmaceutical production, applied in the direction of measuring electrical variables, measuring current/voltage, measuring devices, etc., can solve problems such as reducing production efficiency, increasing equipment costs, and affecting pharmaceutical production, so as to improve production efficiency, reduce use, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

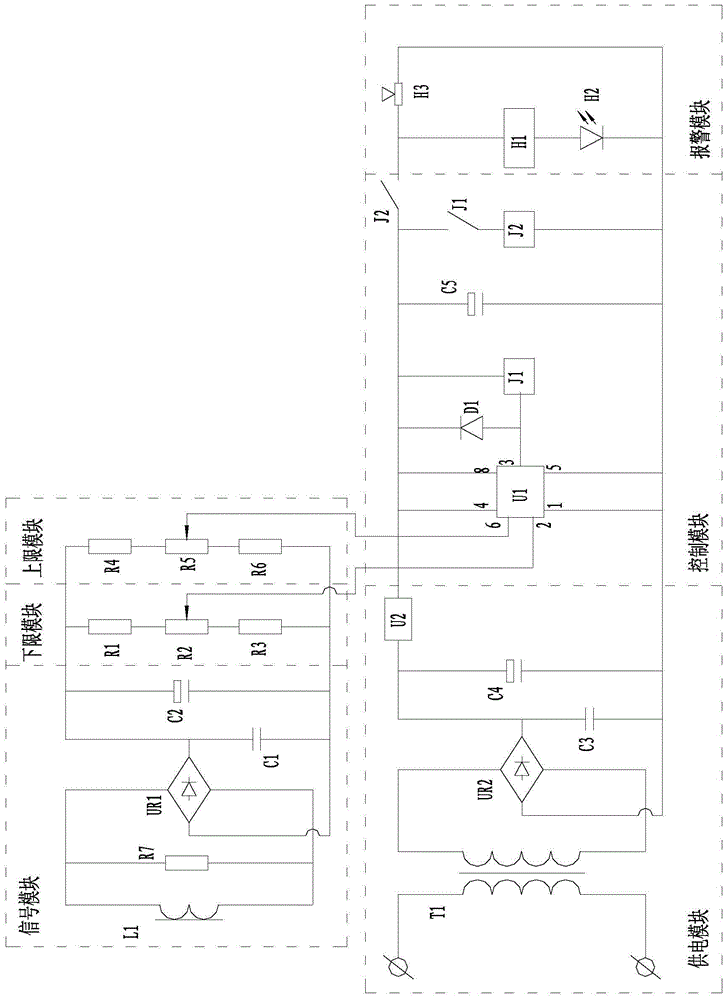

[0028] This embodiment describes a detection and alarm circuit for a stirring pot for pharmaceutical production, such as figure 1 Shown: The circuit includes a power supply module, a signal module, a lower limit module, an upper limit module, a control module and an alarm module.

[0029] Among them, the signal module is used to detect the motor current of the stirring pot, and convert the information of the motor current into an initial voltage signal. The lower limit module and the upper limit module are respectively used for converting the initial voltage signal into a lower limit voltage signal and an upper limit voltage signal. The control module is used to compare the lower limit voltage signal and the upper limit voltage signal with the lower limit set value and the upper limit set value respectively, and control the on-off of the alarm module. The alarm module is used for alarming when the viscosity of the medicine is too high.

[0030]Specifically, the signal module...

Embodiment 2

[0042] The circuit of this embodiment is used for detecting and alarming the viscosity of stirring pots in pharmaceutical production, including a power supply module, a signal module, a lower limit module, an upper limit module, a control module and an alarm module;

[0043] The signal module is used to detect the motor current of the stirring pot, and convert the information of the motor current into an initial voltage signal;

[0044] The lower limit module and the upper limit module are used to convert the initial voltage signal into a lower limit voltage signal and an upper limit voltage signal respectively; the lower limit module is composed of resistor R1, adjustable resistor R2 and resistor R3 connected in sequence; the upper limit module is composed of resistor R4, adjustable resistor R5 and Resistor R6 consists of sequential connections; wherein, resistor R1 and resistor R2 are respectively connected to the output positive terminal of the signal module; resistor R3 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com